Search this article

Improving MOCVD with mass flow and pressure control

Chemical vapor deposition (CVD) describes various methods to create functional coating layers using volatile gas phase compounds. There are many different types of CVD, including but not limited to MOCVD, ALD, CVI, and PECVD.

Metal organic chemical vapor deposition, or MOCVD, describes CVD which uses metal complexes with organic ligands as precursors. As in other CVD methods, MOCVD creates coating layers as these volatile compounds decompose on heated substrate surfaces, typically heated around temperatures between 400°C – 1300°C. Operating pressures for these systems typically run in a vacuum between 10-100 torr. As we will discuss, many MOCVD systems additionally utilize bubblers to vaporize precursors, determining the precursor concentration, growth time, and growth rate. After vaporization, the precursors move by carrier gases such as N2 or H2 to the main growing chamber where they interact with heated substrates as described above.

MOCVD is used to produce various types of powders, fibers, thin and thick films, film heterostructures, single crystals, glasses, as well as their structural varieties (amorphous materials, polycrystalline materials with different microstructures, etc.). MOCVD is the most popular system for production of GaN- and GaAs-based optoelectronic devices, such as light-emitting diodes (LEDs), laser diodes, hetero-bipolar junction transistors (HBTs), high electron mobility transistors (HEMTs), solar cells, and photodetectors.

Benefits of optimizing MOCVD system efficiency

A main advantage of MOCVD is the possibility of forming compact coatings from high-temperature oxides and refractory metals such as iridium and platinum at temperatures well below their typical melting points. These types of coatings are excellent for various manufacturing processes, including building internal combustion engines, jet gas turbine blades, and pyrochemical processing. Such coatings are considered extremely profitable, consisting of 35% of all aerospace components in the multi-billion dollar aviation industry.

Alicat’s mass flow and pressure controllers are ideal for use in MOVCD systems since both flow rates and pressures of captured precursor and carrier gases must be carefully controlled to reach maximum operating efficiency. Here we will discuss several MOCVD system design options where Alicat devices provide repeatable, fast, closed-loop control for important MOVCD variables such as gas flow, pressure, and more.

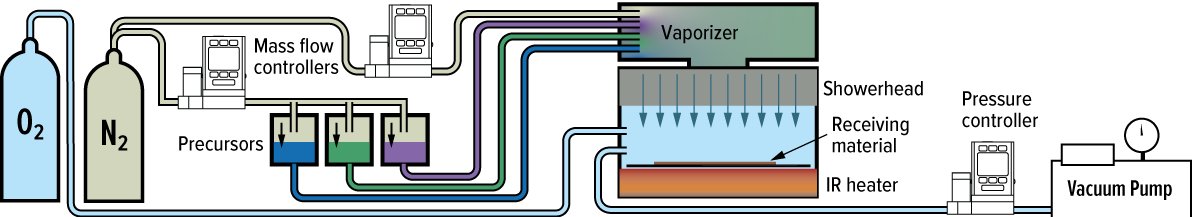

Setup 1: Gas mass flow and pressure control

In the typical MOCVD setup, liquid metalorganic precursors located in separate solution chambers are mildly heated as needed, sparged or bubbled to dissolve the precursor gases, and transported via high purity carrier gas (often nitrogen or hydrogen) into an MOCVD reactor via a temperature-controlled flash-vaporizer. The temperature of this delivery line is precisely controlled to avoid condensation or premature reactions of the precursors prior to their introduction into the MOCVD reactor. The precursors flow with the high purity reactive gases through special orifice manifolds designed to provide uniform deposition and thickness over heated substrates.

In this configuration, a high precision of carrier gas flow rates is critical. Alicat’s mass flow controllers repeatedly and accurately regulate such carrier gas flow rates with the following specifications:

- Control gas flows from 0.5 SCCM to 5,000 SLPM

- Accuracy of ±0.5% of reading or ±0.05% of full scale (whichever is greater)

- Wide control range of 0.01-100% (10,000:1 turndown)

This ensures that correct amounts of precursor gases are bubbled/sparged and flowed into the chemical deposition chambers.

In addition, Alicat’s pressure controllers provide back pressure chamber control, reaching pressure setpoints within 30 ms with NIST-traceable accuracy to ±0.125% of full scale, so that the chemical deposition chamber can hold a constant vacuum between 10-100 torr. Moreover, since carrier gases must remain pure for successful reactions, a low leak rate is ideal in order to limit contamination by ambient gases. Alicat’s pressure and flow controllers each have low leak rates, down to just 10e-9 atm-cc/sec, greatly limiting unwanted gas mixing conditions.

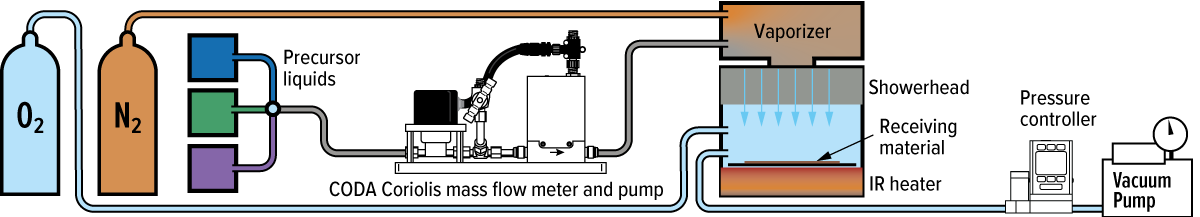

Setup 2: Liquid mass flow and pressure control

Alternatively to the above setup, MOVCD can be more precisely optimized using liquid flow controllers such as Alicat’s CODA KC-Series combined with gas mass flow controllers and pressure controllers. Rather than sparging the precursors as in the previous procedure, liquid flow controllers such as Alicat’s CODA KC-Series carry precise amounts of precursor liquids to the flash-vaporizer. At this point, just as in the previous procedure, the precursors combine with the carrier gas (still controlled by a gas mass flow controller) and flow into the main chemical deposition chamber at vacuum pressures to react with the heated substrate.

Successful operation of this method depends on repeatable and precise liquid precursor flow control at very low flow rates. Alicat’s CODA KC-Series have the following specifications:

- Control the low flow precursor fluids down to 0.8 g/h (40 g/h full scale with a 2-100% control range)

- NIST-traceable liquid flow accuracy of ±0.2% of reading or ±0.05% of full scale (whichever is greater) for precursors, even with changing or unknown composition

- Repeatability of ±0.05% of reading or ±0.025% of full scale (whichever is greater)

Just as in the previous MOCVD configuration, Alicat’s gas mass flow controllers deliver exactly the right amounts of carrier gases needed for the reactions while Alicat’s pressure controllers regulate chamber vacuum back pressures. Moreover, Alicat’s flow controllers provide continuous temperature measurement for additional monitoring of operating conditions.

Additional info

Additionally, in combination with a computer or PLC, Alicat’s gas mass flow controllers and CODA KC-Series liquid flow controllers can easily totalize and batch precursor liquid and gas mixes.

Whether your process requires precision, repeatability, accuracy, or automation, Alicat’s liquid and gas mass flow and pressure controllers provide the latest tech, most unique features, and fastest results for all MOCVD applications.