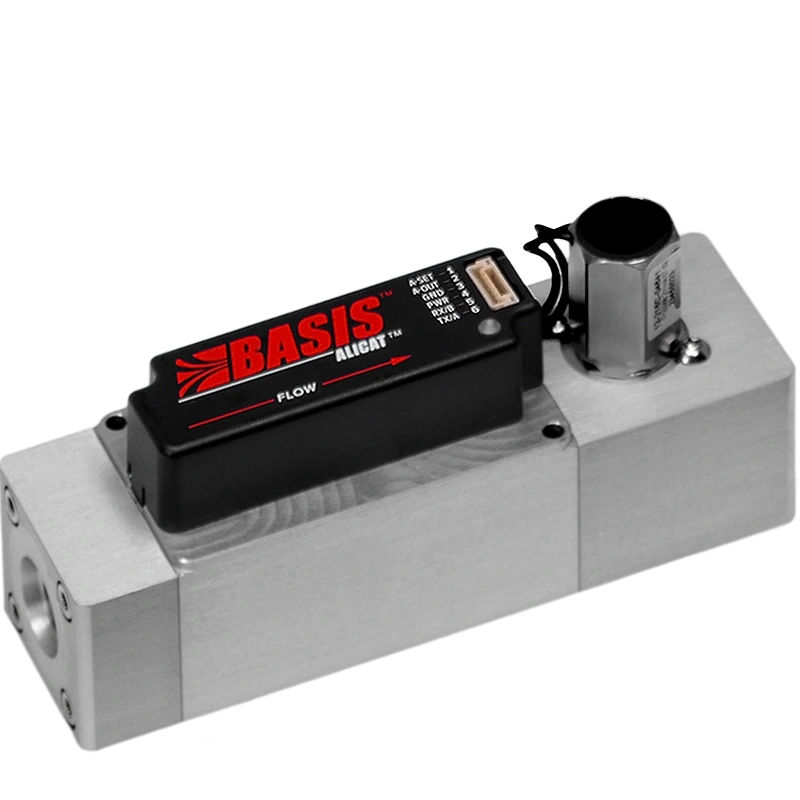

FastTrack Flow & Pressure Devices

FLOW METER RANGES

2 SCCM – 500 SLPM

FLOW CONTROLLER RANGES

Do FastTrack instruments meet your requirements?

Not sure what works best?

Your flow rate, pressure, and choice of gas can all affect which Alicat instruments work for your application.

Our Applications Engineers can answer your questions and help you find the best option.

Related Products

Liquid Flow

Liquid flow meters and controllers use Coriolis or laminar flow sensors to accurately measure or control liquids for many applications. Low flow to higher volume.

Pressure

Pressure transducers or pressure controllers measure or control pressure in flowing, dead-ended or vacuum processes. Dual valve controllers and remote sensing options.

Custom Instrumentation

Flow and pressure instruments crafted to your specifications. Engineered to perform to your unique needs. Customize our products or get wholly new systems—like gas mixers, manifolds, or control loops.

Accessories

Get essential cables and specialized supplies for your meter or controller. Alicat offers breakout boxes for communication to multiple devices, fittings, adapters and more.

Call Us

+1 (888) 290-6060

Live Chat

Ask us a question

Help Near You

Find a local representative

Self Help

Technical documentation

Call Us

+31 262-031-651

Live Chat

Ask us a question

Help Near You

Find a local representative

Self Help

Technical documentation