Search this article

Bioreactor and fermentation research

Alicat has been cited in over 1,000 peer-reviewed research papers. The following papers focus on bioreactors and fermentation and emerging technologies in that field. Contact us if you’d like your research to be highlighted.

Abstract

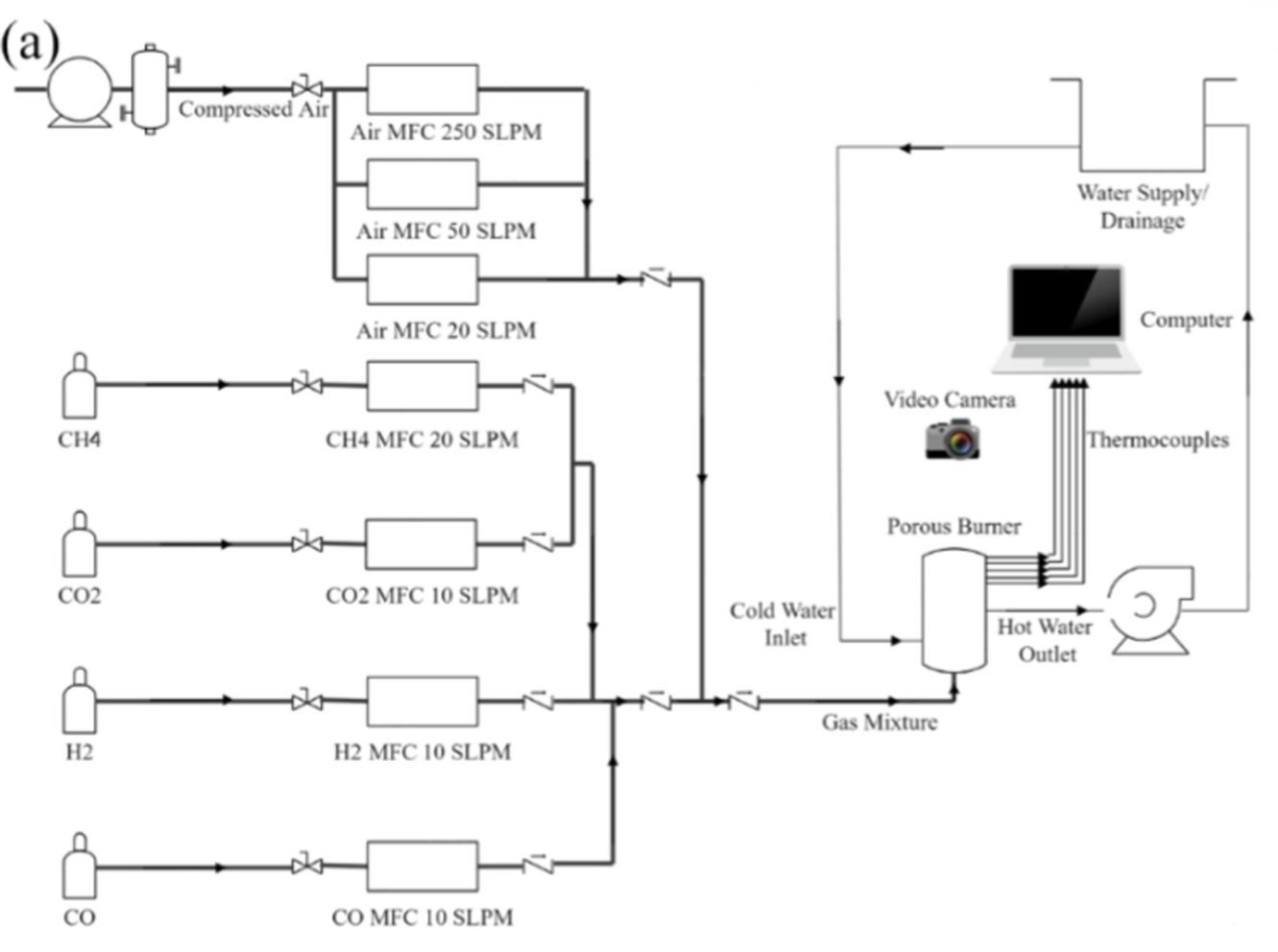

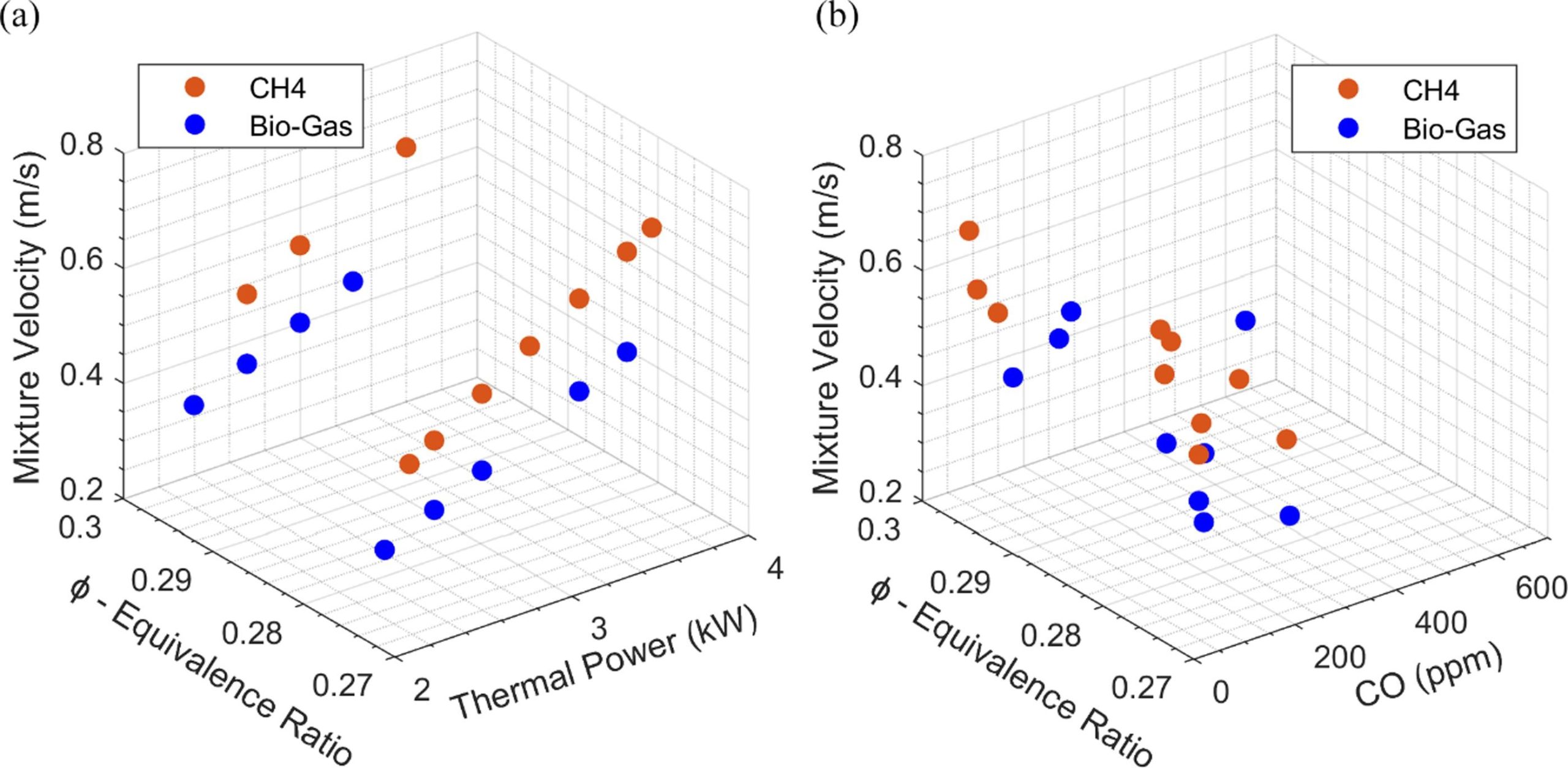

The response of ultra-lean flames, stabilised in a porous burner, to the fluctuations imposed on the fuel flow rate is investigated experimentally. The study is motivated by the likelihood of small biogas generators to produce fuels with temporal variations in their flow rate and chemical composition. The employed porous burner includes layers of silicon carbide porous foam placed inside a quartz tube. The burner is equipped with a series of axially arranged thermocouples and is imaged by a digital camera. Methane and a blend of methane and carbon dioxide (mimicking biogas) are mixed with air and then fed to the burner at equivalence ratios below 0.3. The fuel flow rate is modulated with a programmable mass flow controller by imposing a sinusoidal wave with variable amplitude and frequency on the steady fuel flow.

Schematic of the experimental setup

Through analysis of the flame images and collected temperature traces, it is shown that the imposed disturbances result in motion of the flame inside the burner. Such motion is found to qualitatively follow the temporal variation in the fuel flow for both methane and biogas. Nonetheless, the amplitude of the flame oscillations for methane is found to be higher than that for biogas. Further, it is observed that exposure of the burner to the fuel fluctuations for a long time (180 s) eventually results in flame destabilisation. However, stabilised combustion was achieved for methane mixtures at amplitudes between 0 and 30% of steady values over a period of 60 s. This study reveals the strong effects of unsteady heat transfer in porous media upon the fluctuations in flame position.

Steady CH4/Biogas mixtures (a) Equivalence Ration vs. Thermal Power (b) Equivalence Ration vs. CO emissions

Reference

Habib, R., Yadollahi, B., Saeed, A., Doranehgard, M. H., Li, L. K. B., & Karimi, N. (2021). Unsteady ultra-lean combustion of methane and biogas in a porous burner – an experimental study. Applied Thermal Engineering, 182, 116099. https://doi.org/10.1016/j.applthermaleng.2020.116099

Abstract

This paper details the development, validation, and analysis of a conceptually correct mathematical model for biogas upgrading biological trickling filter (BTF) reactors. The model considers convective transport and dispersion of gases through the fixed bed and mass transfer and reaction of absorbed gases in immobilized biofilms. Wetted and non-wetted biofilms, gas volume contraction through the bed as hydrogen and CO2 are converted to methane, and axial dispersion were all included in the model. The model successfully predicted the performance of a laboratory scale BTF upgrading various raw biogas compositions.

A parametric sensitivity analysis revealed that the influent gas flow rate, biofilm specific surface area, and maximum rate of reaction (Rmax) were the most sensitive parameters. Furthermore, reducing the wetted biofilm ratio by 54% (12% wetted) was the easiest optimization measure for achieving renewable natural gas standards (>97% effluent methane).

Practically, this could be achieved e.g., by applying an intermittent trickling regime. The liquid-film mass transfer coefficient (kLa) was not a sensitive parameter. This was because the model predicted that a majority of substrate conversion was occurring in the non-wetted biofilm, a finding that further supports the importance of reducing biofilm wetting in these BTFs. Overall, the model provides a strong conceptual framework for future studies modeling biogas upgrading processes. Additionally, it has the potential to be a useful tool in scaling and optimizing BTF bioreactors for biogas upgrading applications.

Reference

Dupnock, T. L., & Deshusses, M. A. (2020). Development and validation of a comprehensive model for biotrickling filters upgrading biogas. Chemical Engineering Journal, 407, 126614. https://doi.org/10.1016/j.cej.2020.126614

Abstract

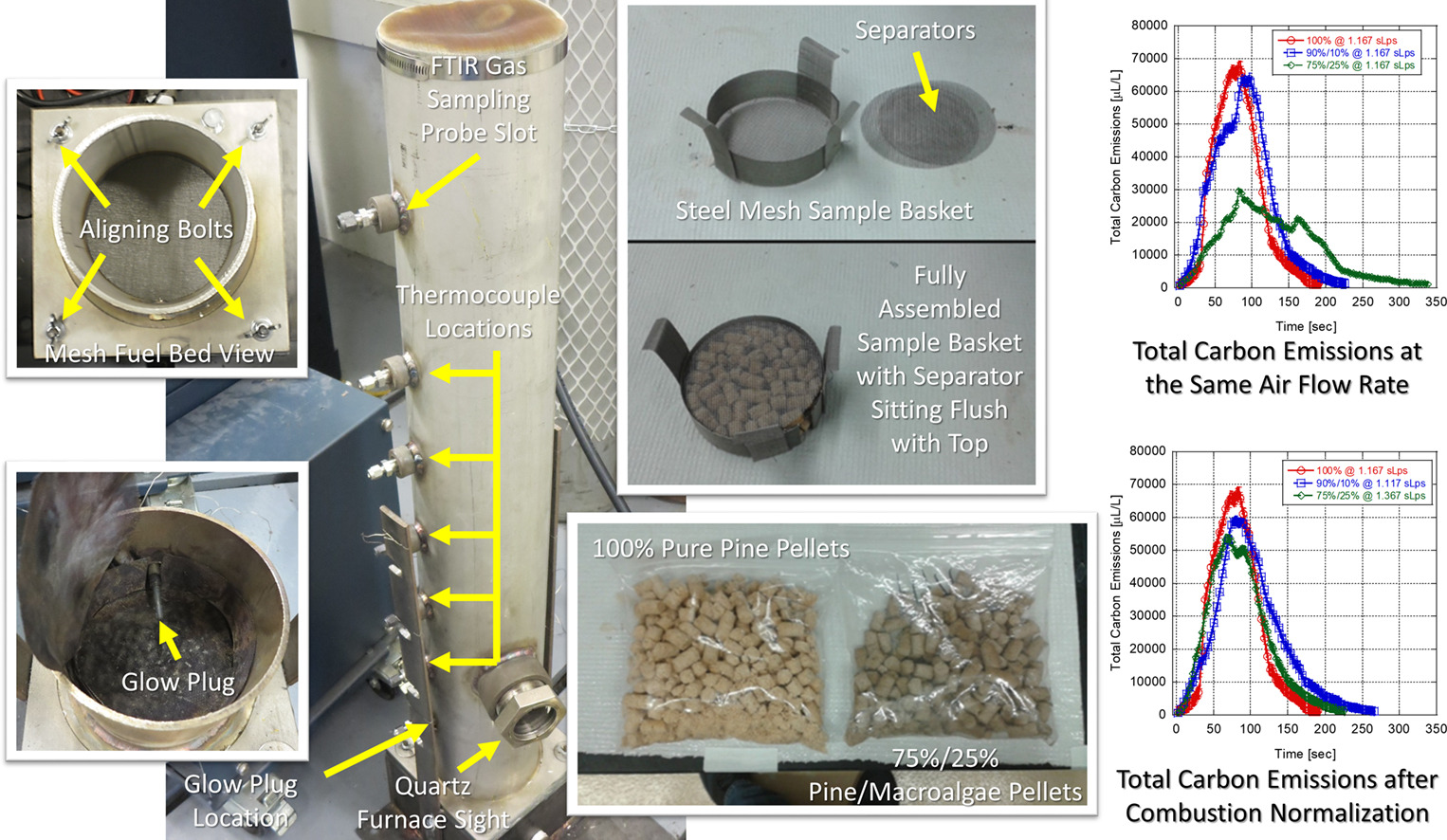

Freshwater macroalgae are an underutilized group of ubiquitous algae with greater yield potentials than most terrestrial energy crops, but whose combustion characteristics are not thoroughly understood. This effort compared the combustion of pelletized 100% pine and macroalgae-containing solid fuel mixtures (90%/10% and 75%/25% pine/macroalgae) using a fixed bed co-current reactor. Macroalgae increased pellet density as its protein and calcium content promoted hydrogen bonding and cross-linked the carboxylic acid functionality of polysaccharides.

In addition, higher concentrations of freshwater macroalgal biomass required a greater air flow rate to achieve the mixing required for combustion. Since the macroalgae had a higher level of fuel nitrogen and fuel sulfur, emissions of nitrogen and sulfur oxides largely grew with an increasing proportion of this fuel. Overall, pelletized macroalgae can be co-combusted with woody biomass and its pre-treatment (water-rinsing and modulating cultivation conditions) can reduce or eliminate drawbacks found in the harvested naturally-occurring algal material.

Reference

Gessler, B., Jalal, A., Yun, J., Peltier, E., & Depcik, C. (2021). Combustion of pelletized freshwater macroalgae and pine blends using a fixed bed reactor. Bioresource Technology Reports, 16, 100871. https://doi.org/10.1016/j.biteb.2021.100871

Abstract

The boil-off gas (BOG) produced from liquefied natural gas (LNG) mixtures in cryogenic storage tanks must be predicted reliably as a function of tank shape, heat ingress, thermal stratification, pressure, and liquid volume fraction. However, current methods of estimating BOG rates for large-scale tanks are entirely empirical and based on limited available data, with no models available for reliable predictions. This affects the ability of LNG carriers to optimise BOG compressor sizing. A new apparatus was developed to explore the effects of heat flux, liquid stratification, volume, and mixture composition on the measured boil-off rate.

The apparatus is demonstrated using liquid nitrogen with BOG rates quantified as a function of various heat fluxes, pressures, and initial liquid volume fractions. Three distinct periods of boil-off were observed: the pressurisation, transient, and steady-state stages. The data are compared with the available literature and the predictions of a new dynamic model accounting for heat transfer from the super-heated vapour. Excellent agreement is observed between model predictions and the data measured during the pressurisation and steady-state stages. However, the model does not capture the BOG rate observed in the transient stage, suggesting liquid thermal stratification should be considered in future models for LNG boil-off.

Reference

Perez, F., Al Ghafri, S. Z. S., Gallagher, L., Siahvashi, A., Ryu, Y., Kim, S., Kim, S. G., Johns, M. L., & May, E. F. (2021). Measurements of boil-off gas and stratification in cryogenic liquid nitrogen with implications for the storage and transport of Liquefied Natural Gas. Energy, 222, 119853. https://doi.org/10.1016/j.energy.2021.119853

Abstract

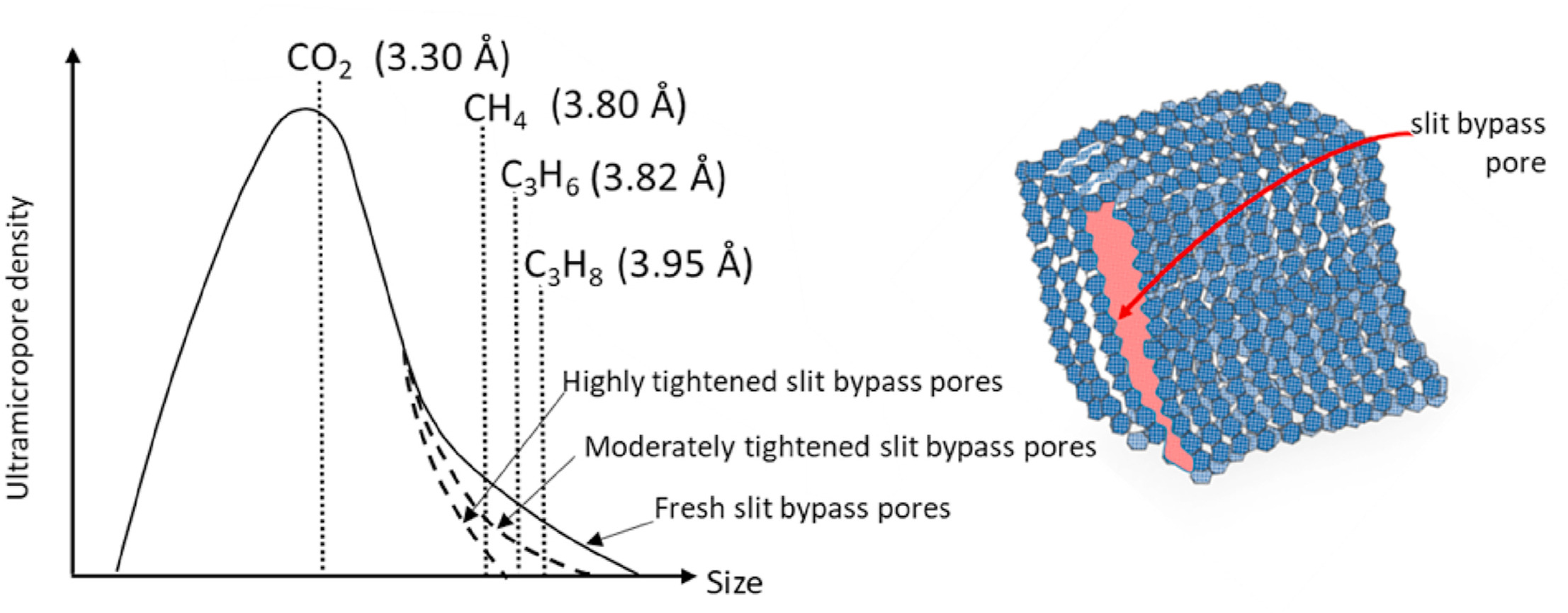

Economically scalable carbon molecular sieve (CMS) hollow fiber membranes rely upon a tunable bimodal pore morphology to separate gas pairs using angstrom-level size discrimination. Freshly formed CMS membranes experience self-retarding physical aging, reflected by permeance losses and selectivity gains that stabilize over short times compared to the lifetime of the membrane. Self-retarding morphology rearrangements are of special interest here due to tightening of the largest size range of ultramicropores, thereby causing aging for polyimide-derived CMS. We report effects of such aging for two A/B penetrant pairs, C3H6/C3H8 and CO2/CH4. These two pairs not only have different average sizes, d¯A/B, but also different size differences,ΔdA/B, between the members in each pair.

We focus primarily on the C3H6/C3H8 pair, which is the most difficult of the two pairs to separate, and use some CO2/CH4 results as a comparison case. We study CMS derived from 6FDA:BPDA-DAM (1:1) polyimide by pyrolysis at 550 °C, 600 °C and 650 °C. We suggest conditions and physical causes that expedite, retard or even suppress the aging process within CMS membranes. Finally, we suggest how analysis of CMS derived from other precursors and other penetrant pairs can be generalized by understanding the results for the 6FDA:BPDA-DAM (1:1) polyimide derived CMS.

Reference

Reference

Arab, P., Liu, Z., Nasser, M., Qiu, W., Martinez, M., Flick, D., Roy, A., Liu, J., & Koros, W. J. (2021). Subtle penetrant size effects on separation of carbon molecular sieve membranes derived from 6FDA:BPDA-Dam Polyimide. Carbon, 184, 214–222. https://doi.org/10.1016/j.carbon.2021.08.005