Search this article

Alicat mass flow controllers resist back pressure contamination

Evaluation of Alicat mass flow controllers’ resistance to back pressure contamination

Mass flow controllers (MFCs) are essential to many modern production and test processes. Precise and reliable flow control is particularly important for efficient, sustainable production in applications such as glass fabrication and bioprocessing. Within such processes, MFCs occasionally face the challenge of encountering unexpected water or foam contamination. This is especially common in bioprocessing applications, where large quantities of liquid and foam/film can lead to gas buildup. This can increase the downstream pressure, introducing the potential for contamination of upstream process devices with biological materials and culture media.

This buildup leads to decreased accuracy in thermal conductivity-based flow designs1. Alicat’s differential pressure-based mass flow meters and controllers, on the other hand, are more resistant to errors caused by this type of contamination – but just how resistant are they? We set up an experiment to simulate contamination of an Alicat MFC with foamy liquid and examined its effects on the MFC’s ability to accurately control mass flow.

Experimental setup

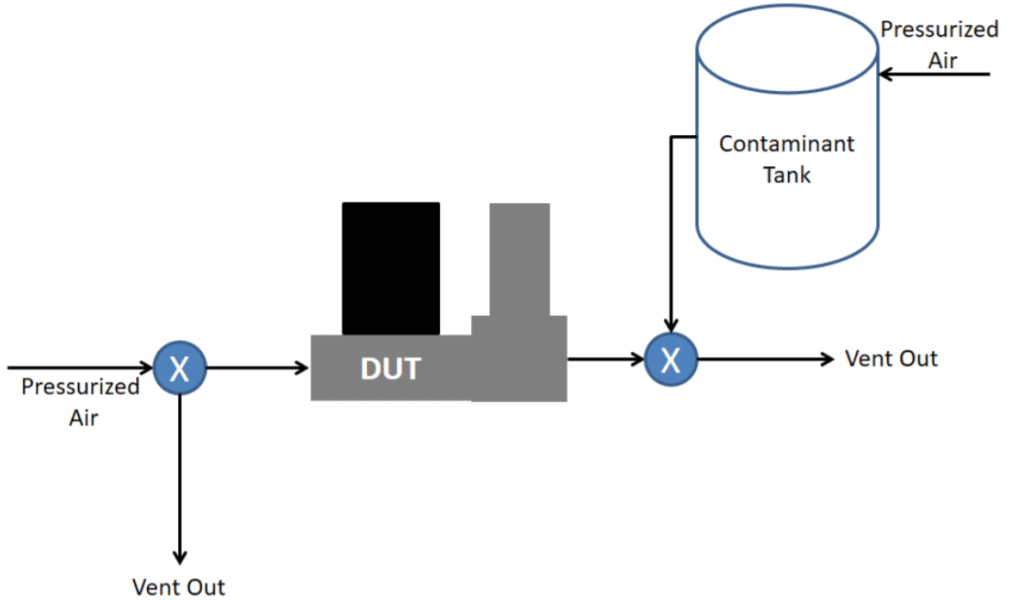

Figure 1. Schematic of experimental setup. Blue circles represent 3-way valves; DUT = device under test.

To simulate the conditions under which the unit might be contaminated, we created and installed a pressurized foam contaminant tank downstream of the MFC (see Figure 1). Foam was made using a mixture of yeast, 3% hydrogen peroxide solution, and dish soap – simulating a biological contaminant. An Alicat Bio-Series2 1 SLPM mass flow controller was used for the test. This series uses materials compliant with ASME BPE-2016 standards3, and includes additional features to facilitate use in a bioprocessing environment. Its performance under these conditions should be representative of other Alicat MFCs as well. Foam was generated and the contaminant tank was pressurized to 40 PSIG, 60 PSIG, and 80 PSIG. 12.45 mL of the foam solution was repeatedly introduced into the MFC at various pressures; accuracy and control ability were then measured at 16 ± 1 minutes after each contamination event.

Results

The Alicat MFC was surprisingly resistant to contamination from watery foam. Anecdotal reports had indicated that the unit would likely respond poorly to even slight contamination events. Loss of accuracy and control due to contamination with process fluids is common with thermal-based MFCs1. However, despite repeated contamination events, the Alicat MFC continued to perform within normal operating parameters.

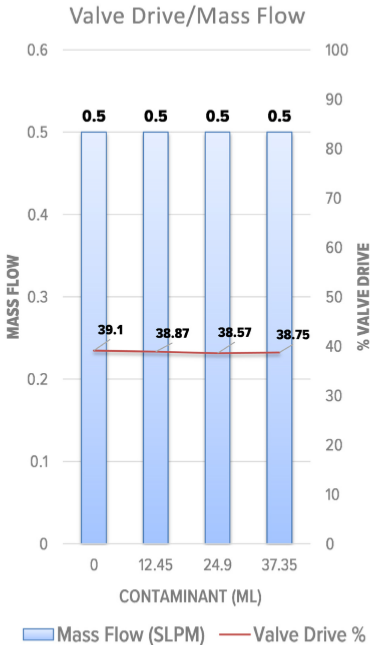

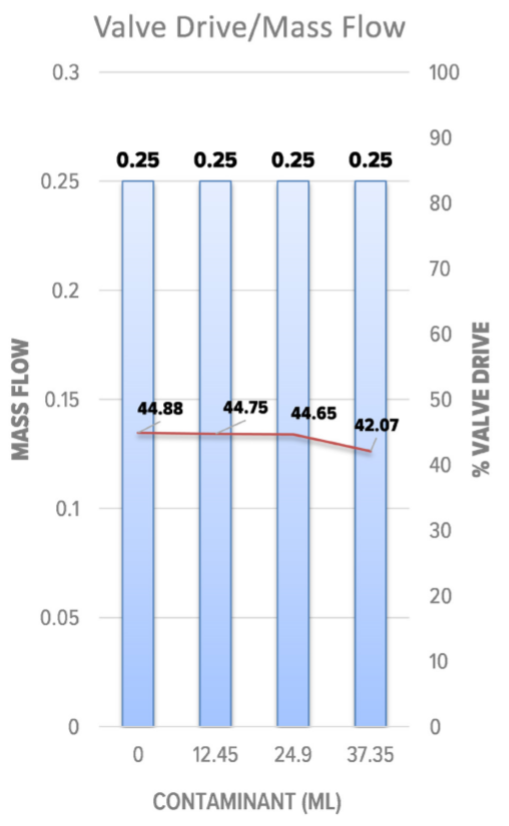

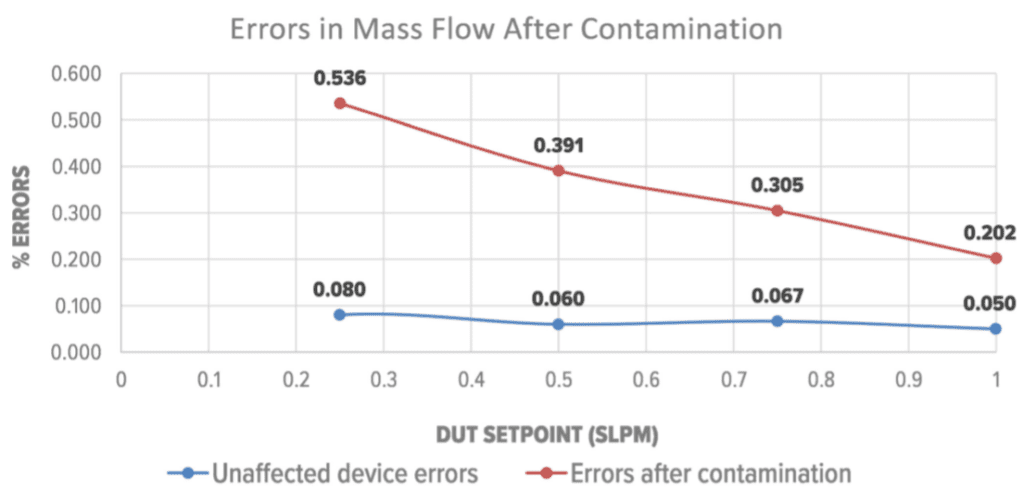

For each set of experiments, we measured the mass flow that the unit was controlling to (in SLPM), as well as the valve drive percentage of scale used (see Figures 2 and 3). Prior to each contamination, measurement accuracy was verified by comparison with a Molbloc standard4,5. The percentage errors before and after contamination are shown in Figure 4. We observed much higher errors after contamination than in the original state; however, the absolute magnitude of the errors is still less than 1% of the reading. The errors after contamination decrease linearly with the mass flow rate setpoints, which may be an indication of a small blockage caused by the contamination. The errors are reduced by approximately half once the device is purged with isopropyl alcohol and subjected to vacuum, to dissolve any residue left behind from the foam and to evaporate the alcohol remaining inside the device.

After both sets of tests were completed, we tested the device to failure by repeatedly flooding it with partially foamy water, in excess of 100 mL, until the foam reached the flow meter and was detected upstream of it. After repeated attempts to induce failure, the device was still functional, but began controlling erroneously.

Figure 2. Valve drive percentage and mass flow (SLPM) at 22 psig input pressure.

Figure 3. Valve drive percentage and mass flow (SLPM) at 73 psig input pressure.

Figure 4. Errors at various stages of testing

Discussion

MFCs are an essential control unit for many industrial processes. This is especially true in a bioreactor environment, where fragile cells depend on proper flow of oxygen for metabolism and carbon dioxide for pH control. We have many anecdotal reports that the robust nature of our differential pressure-based MFCs are an advantage to our customers. The experiments described here are one of the first investigations into defining exactly how much process contamination an Alicat MFC can withstand. The results from these experiments suggest that limited transient contamination with water-based foam, even foam containing substantial biomaterial, has little effect on the controller’s operation.

Alicat MFCs have the ability to report valve drive percentage: this feature reports what percentage of the voltage range is being used to maintain the valve position. Under conditions where it is more difficult to open the valve (typically at higher pressures or in instances of valve contamination), the drive percentage will increase. In the experiments here, however, the valve drive percentage remained constant, suggesting that the valve did not find it increasingly difficult to control flow.

We also measured the reported mass flow vs. actual mass flow using a Fluke Mobloc calibration standard. Even after repeated exposure to the foam solution (in excess of 35 mL within a short time), the device’s flow accuracy changed by less than 1%. While we expected the unit to perform in a robust fashion, these results exceeded our expectations. In order to ensure that our methodology was sound, the device was then flooded completely with the foam solution. Under conditions where most devices would cease to function, the Alicat MFC continued to report and control mass flow. However, when verified with the Mobloc, the mass flow reported was only 25% of the actual flow. Thus, we were able to finally cause the unit to fail in controlling flow accurately. The affected unit was then purged with isopropyl alcohol and vacuum dried at 10-3 torr for one hour before being sent to Alicat’s service department for analysis.

Alicat’s service department concluded that the device was undamaged. The contamination did not affect the sensor performance and the unit displayed no significant deviation from its original state. While we never recommend subjecting an Alicat MFC to this type of harsh treatment, these results verify the anecdotal evidence: under conditions were a thermal MFC would typically fail, an Alicat MFC continues to accurately report and control flow.

Conclusions

1. No significant effect was observed on the device performance, including the valve, when only the valve was flooded with the contaminant.

2. When the mass flow controller was flooded, the calibration of the device was observed to deviate within the correct values.

References

1. Shannon, W. How to Overcome 9 Thermal Mass Flow Meter Limitations. Sage Metering Available at: https://sagemetering.com/overcome-limitations/.

2. Operating Manual for MFCs. Alicat Scientific (2019).

3. ASME Standard. Bioprocessing Equipment ASME BPE-2016. (2016).

4. Delajoud, P., Bair, M., Rombouts, C. & Girard, M. A Primary Calibration System for the Support of High Performance Gas Flow Transfer Standards. In 2006 ISFFM 1, 1–6 (2006).

5. Bair, M. Uncertainty Analysis For Flow Measured By molbloc-L And molbloc-S Mass Flow Transfer Standards. (2009).