Search this article

Fast, accurate leak testing using one flow controller

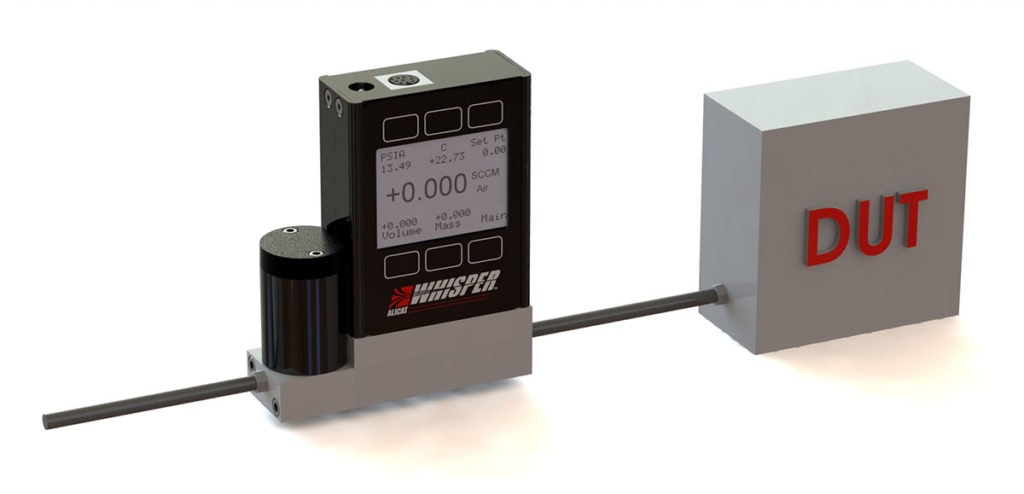

Leak testing setup using a Whisper-Series mass flow controller configured to act as a pressure controller and measure flow.

Looking for a fast, accurate way to leak test your system? Whisper low pressure drop controllers provide a convenient, single instrument solution. A standard controller may also work, however stable leakages are best detected when the meter generates minimal pressure drop (line pressure due to frictional resistance). This makes the low pressure drop (as low as 0.07 PSID) of a Whisper quite useful, especially when leak testing smaller volumes such as valves or sensors.

An Alicat mass flow controller simultaneously displays flow, pressure, and temperature readings and can control either flow or pressure. In the setup above, a single Whisper controller is able to maintain a constant pressure at the device under test (DUT) while providing accurate, real-time mass and volumetric flow readings. When the DUT is subjected to a constant pressure within the closed system, any resulting flow is a direct measure of the DUT’s leakage.

Watch the video below for a demonstration of the leak testing setup:

Speak with an applications engineer about your leak testing setup