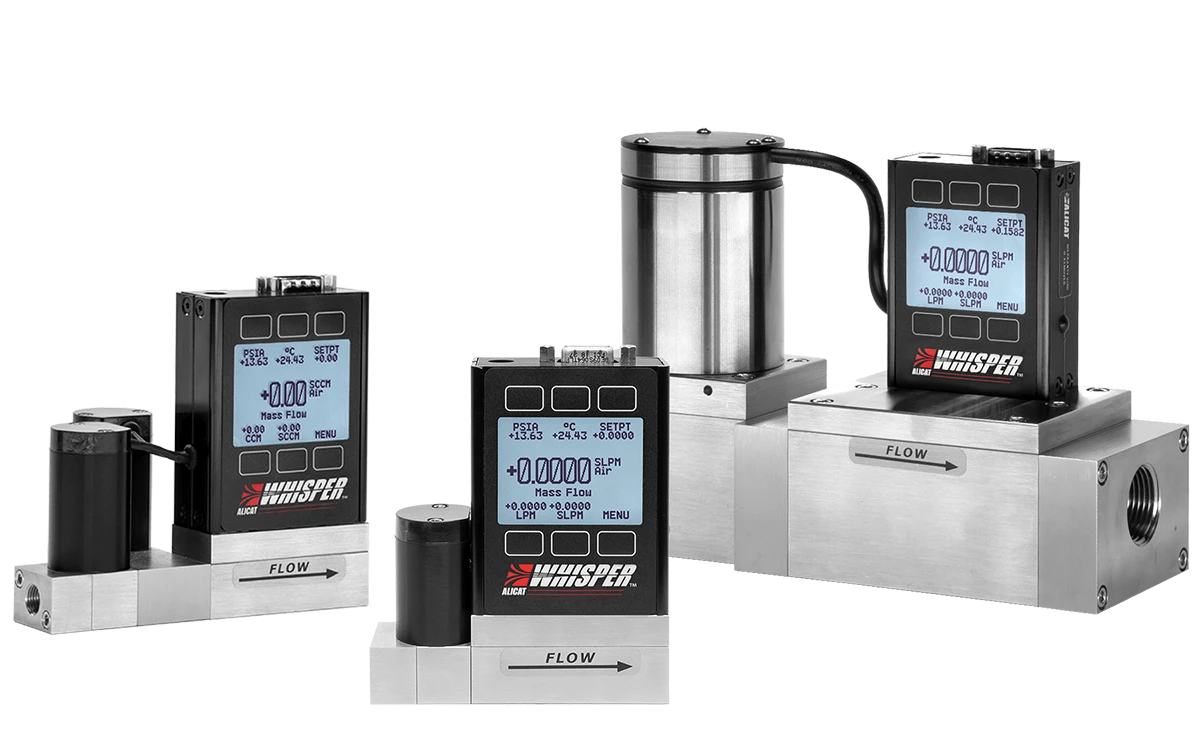

MCW Series Controller

For gas control with low pressure drop

fast proportional control

- 0.5 SCCM – 1,000 SLPM options

- 60 PSIA max operating pressure

- Accuracy as good as ± 0.6% of reading or ± 0.1% of full scale, whichever is greater

- 0.5 – 100% of full scale control range (200:1 turndown)

- 30 ms control response

Spec Sheets

MCDW Series Controller

For bi-directional flow applications

Control in both directions

- 0.5 SCCM – 500 SLPM options

- 60 PSIA max operating pressure

- Accuracy as good as ± (0.4% of total span from positive full scale to negative full scale)

- 0.5 – 100% of full scale control range (200:1 turndown)

- 100 ms control response

- Controls pressure in a closed volume, measures flow rate (leak checking)

Spec Sheets

Available Variants

MC Series Controller

Our standard laminar DP MFCs

SFF / MCV Series Controller

Control gas at vacuum pressures, SEMI footprint options

IS-Max Series Controller

Intrinsically safe MFC for explosive atmospheres

Build Options

Communication Protocols

RS-232 Serial (default)

RS-485 Serial

Analog (4-20 mA, 0-10 Vdc, 0-5 Vdc, or 1-5 Vdc)

Modbus RTU (over RS-232 or RS-485)

Modbus TCP/IP

DeviceNet

EtherCAT

EtherNet/IP

PROFIBUS

PROFINET

IO-Link

RS-485 Serial

Analog (4-20 mA, 0-10 Vdc, 0-5 Vdc, or 1-5 Vdc)

Modbus RTU (over RS-232 or RS-485)

Modbus TCP/IP

DeviceNet

EtherCAT

EtherNet/IP

PROFIBUS

PROFINET

IO-Link

Process Connections

Ingress Protection

Hazardous Environment Ratings

For explosive environments, see the IS-Max Series

Humid Gases

Relative humidity compensation

FastTrack Flow & Pressure Devices

Alicat instruments built and shipped just 3 – 5 business days from your order.

Alicat instruments built and shipped just 10 – 15 business days from your order.

CALIBRATION

Standard or High Accuracy

DISPLAY

Monochrome, Color, or None

PROTOCOL

Analog, RS-232, RS-485, Modbus RTU, PROFIBUS, EtherNet/IP, EtherCAT, MODBUS TCP/IP, or PROFINET

CONNECTOR

MD8, Locking Industrial, DB9M, DB15

FITTINGS

NPT

FLOW METER RANGES

2 SCCM – 500 SLPM

FLOW CONTROLLER RANGES

2 SCCM – 100 SLPM

PRESSURE METER RANGES

1 – 100 PSI

SINGLE AND DUAL VALVE PRESSURE CONTROLLER RANGES

1 – 100 PSI

Do FastTrack instruments meet your requirements?

Ready for the final details?

Each product is made-to-order. Alicat’s Applications Engineers are ready to provide expertise and discuss custom options, ensuring the best fit for your needs.

Downloads

Manuals

Brochures

Software & Utilities

Service and Support

Whether it is time for your instrument’s annual recalibration or your instrument needs a repair or upgrade, you can fill out the Service Request Form below, email us, call us, or start a live chat session to get the service process started.

Call Us

+1 (888) 290-6060

Live Chat

Ask us a question

Help Near You

Find a local representative

Self Help

Technical documentation

Call Us

+31 262-031-651

Live Chat

Ask us a question

Help Near You

Find a local representative

Self Help

Technical documentation