Applications and use cases

Benefits of Alicat’s main-line technology

- 10,000:1 turndown ratio enables flexible placement and reduces the need for multiple flow lines

- Repeatable and stable measurement remains accurate across varying temperatures and conditions

- Highly configurable devices specified to custom application requirements and system setups with highly versatile communication options

- Fast response times provide rapid control times, as low as 30 ms

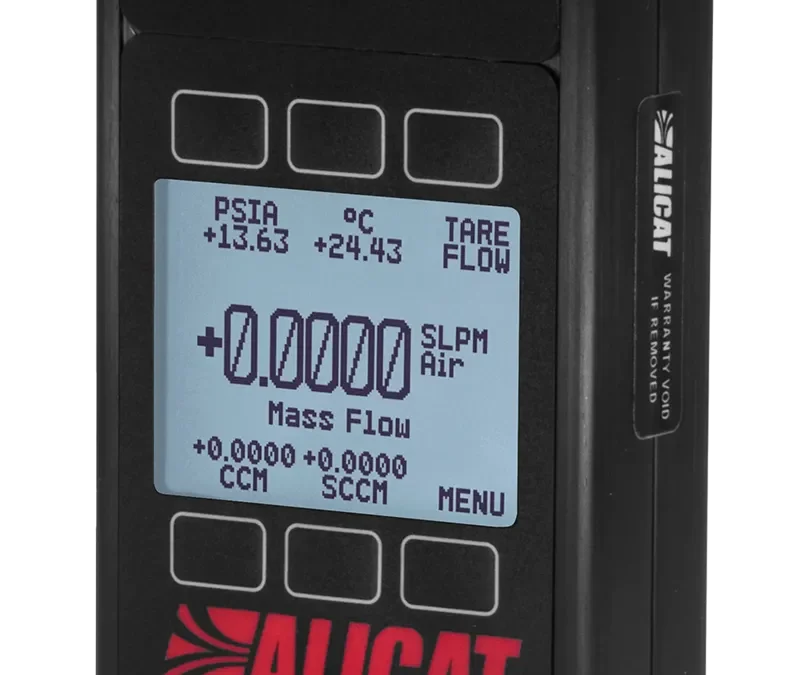

- Integrated display & reporting that shows real-time, configurable flow and pressure data

- No recalibration during gas change with 98 – 130 pre-loaded gas calibrations that devices can switch between without losing accuracy

Related articles

What Are Gas Mixers?

Countless industrial processes, consumer applications, and areas of academic study require finely‑tuned gas mixtures in...

Portable Flow Meters to Leak Test Bioreactors

Bioreactors must be leak tested to ensure all seals are tight and that there are no holes or gaps in equipment. Portable flow...

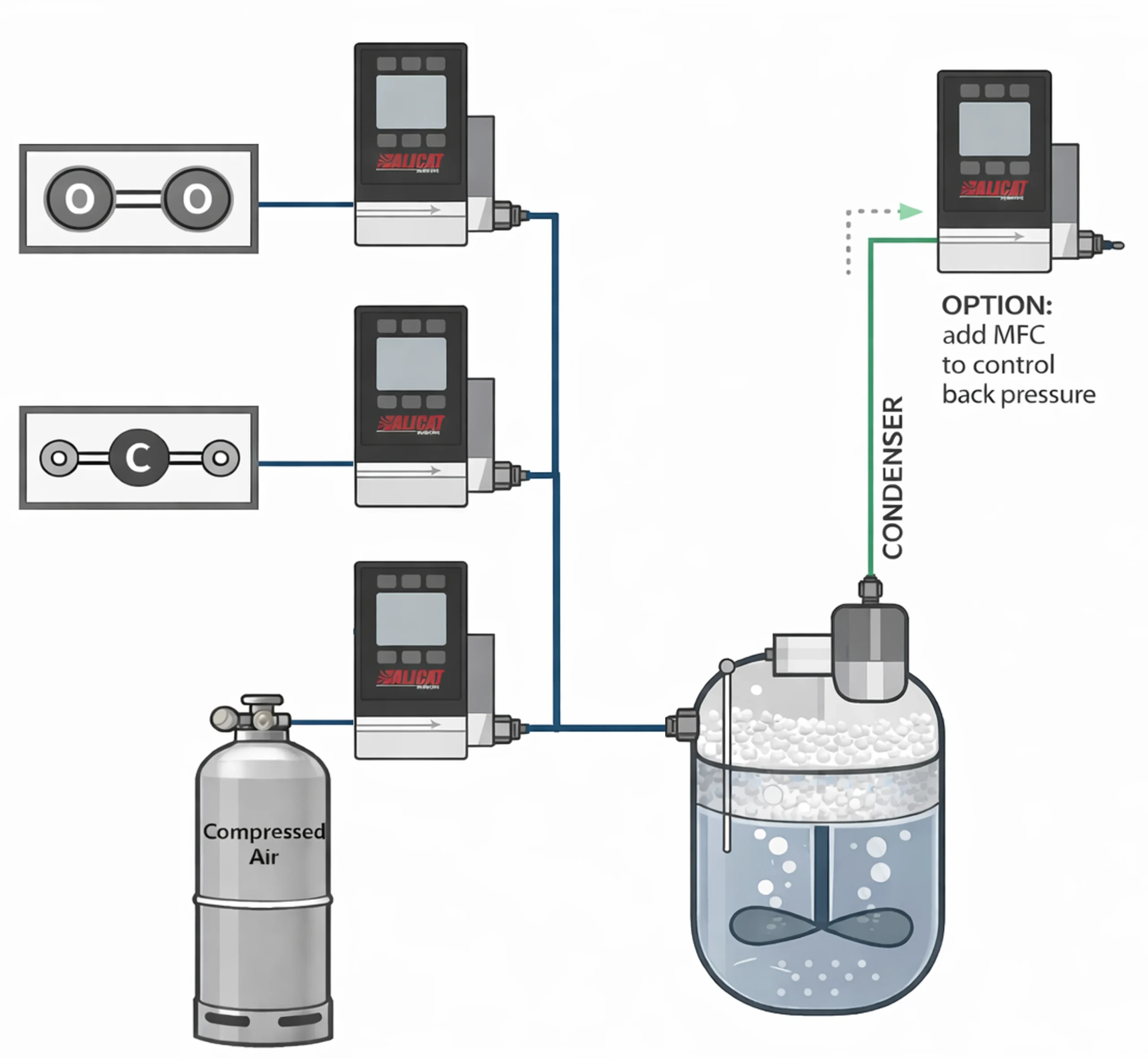

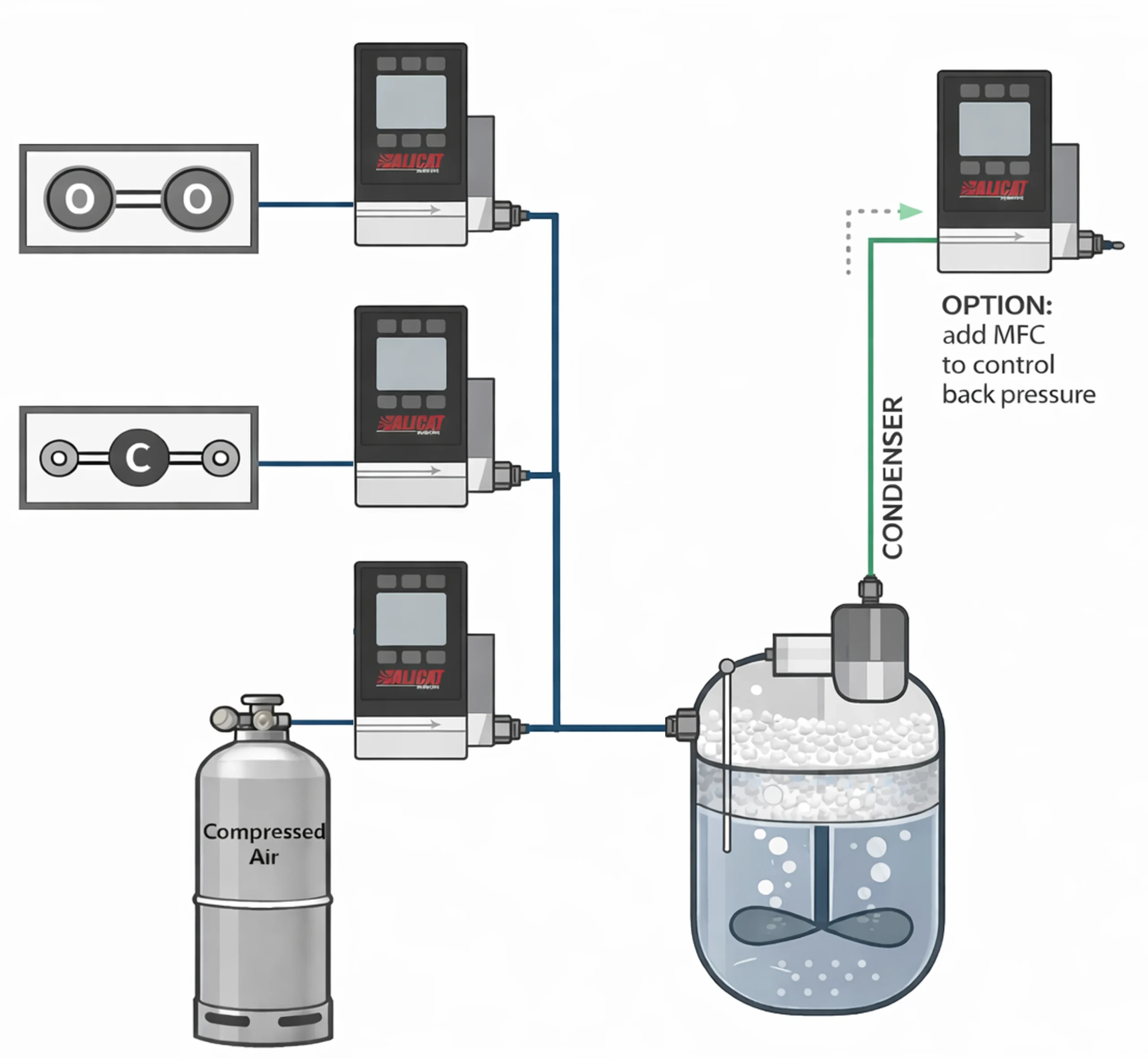

Control Systems for Benchtop Bioreactors

In the past, successes and failures of large‑scale biologics production could largely be attributed to the experience of...

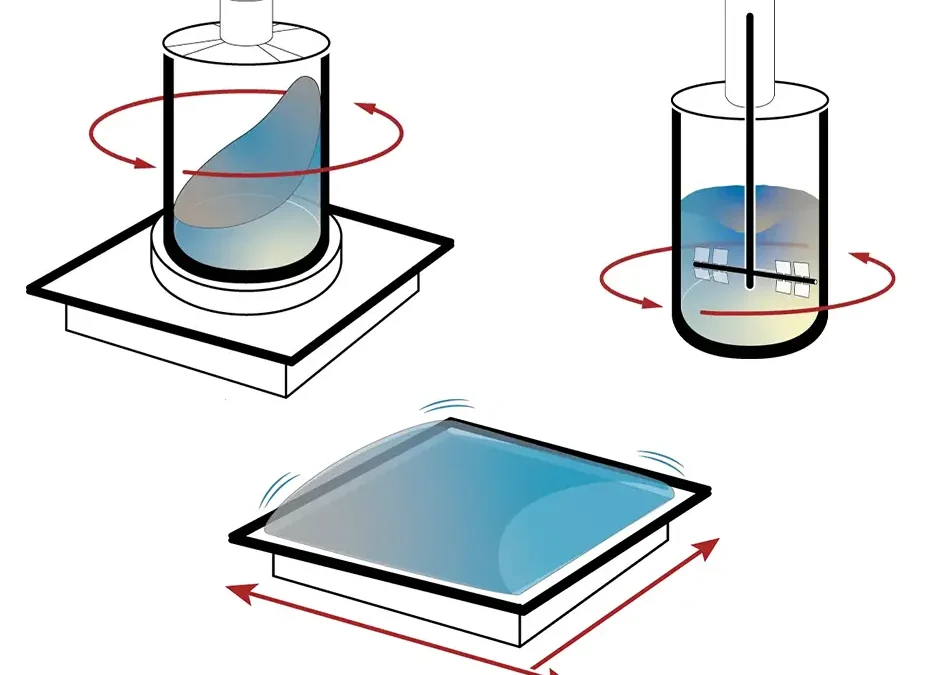

Shakers, Rockers, and Stirred Tank Bioreactors – Advantages of Each

We’ve previously written articles comparing single‑use bioreactors to stainless steel or glass multi‑use bioreactors. You can...

Related products

Ask an engineer

Your flow rate, pressure, and choice of gas can all affect which Alicat instruments work for your application.

Our Applications Engineers can answer your questions and help you find the best option.

Call us

+1 (888) 290-6060

Live chat

Ask us a question

Help near you

Find a local representative

Tech docs

Reference materials