Control Systems for Benchtop Bioreactors

Process analytical technology (PAT) focuses on incorporating sensor data into system-level controls to provide precise, real‑time monitoring and control of various process parameters — and bioreactor systems are largely ahead of the curve in their adoption of PAT technologies.

Smart sensors and advanced analytics have clearly and consistently provided better control and scalability of bioreactor processes. The ability to monitor and analyze key process parameters has made it easier for scientists and manufacturers to move processes between benchtop research, troubleshooting, pilot, and production environments.

Benchtop control systems mean compromising between flexibility and scalability

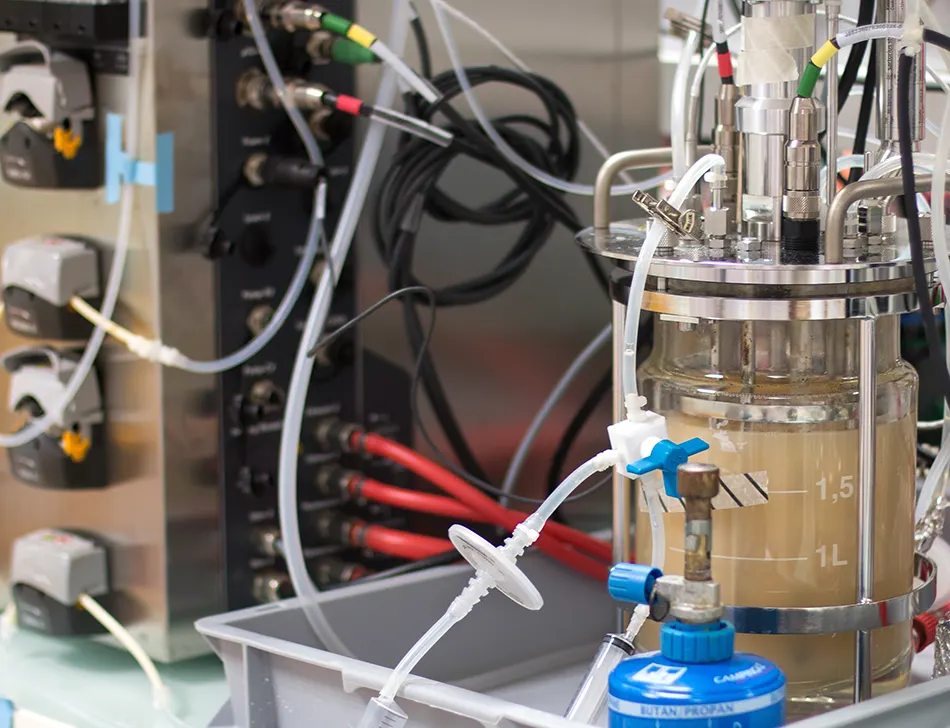

For these reactors, control systems are generally highly flexible, designed for modularity or easy configuration with a variety of physical features and sensors. This allows the researcher to experiment with a mix of spargers, impellers, probes, dip tubes, and other sensors and equipment.

This setup gives the researcher flexibility to determine optimal values for key process parameters — but it is not very scalable. The next step is to redesign the process for scalability, using control systems that will grow with the process development group.

Process development systems enable scaling up and down

For both system types, appropriately monitoring and controlling process parameters is key to success. While this is of course true for parameters such as oxygen transfer and uptake rates, it is equally important to ensure that the sensors and control system will successfully scale.

For instance, vessel material, size, shape, and stirring mechanism can all stay constant, largely regardless of process phase. But parameters such as bubble size, which has a direct effect on oxygen uptake, must be optimized for each new culture size and bioreactor configuration, and cannot be fully determined at the benchtop.

Some controllers are designed to handle a wide array of applications and culture types at the benchtop level. While these controllers are highly flexible, they are not designed for scalability. For example, bioreactors and fermenters can often be used interchangeably for cultures up to 1 liter. At larger scales, however, the different processes require equipment specialized to either microorganisms or microbes.

Other controllers are more conveniently designed to be used across multiple process phases, with a single interface focused on scaled data handling and the ability to easily integrate with a SCADA.

Monitoring per PAT directive allows for better process control

There are significant advantages to monitoring these variables as early in development as possible. By establishing process conditions at benchtop and carrying those through to manufacturing operations, engineers and scientists are able to better understand and control their processes, leading to more precise scale‑ups and simpler troubleshooting at any step of the process.

For example, back pressure is most often only measured in production environments, largely for control of steam‑in‑place. However, the back pressure on a bioreactor also impacts oxygen mass transfer and uptake, providing information needed to maximize oxygen uptake by cells. A bioreactor control system designed to measure back pressure therefore gives us information on the culture growth that would otherwise have been unavailable, and gives us better control over scaling with the process.