Thin Film Deposition Techniques

What is thin film deposition?

Thin film deposition involves applying extremely thin material layers to a substrate. These coatings play an essential role in semiconductors, solar cells, optics, and various other applications that specifically demand precision in thickness and uniformity.

Thin film deposition techniques enhance the surface properties of engineering components by applying thin (< 1 micron) material coatings. As a result, these modifications can improve conductivity, corrosion resistance, wear, fatigue strength, hardness, and more, depending on the material and application.

Common thin film applications include:

- Electronic components and displays

- Optical coatings

- Biomedical devices

- Solid surface coatings

- Data storage systems

Thin film deposition techniques

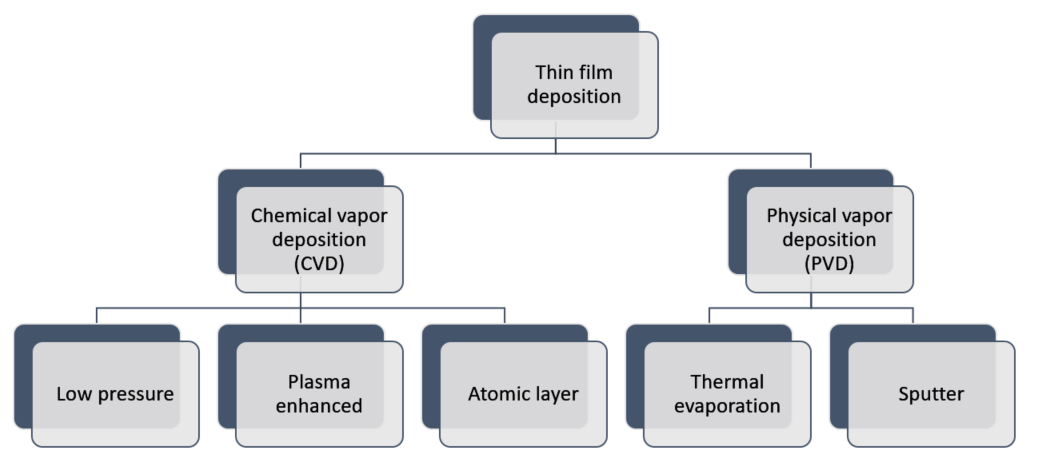

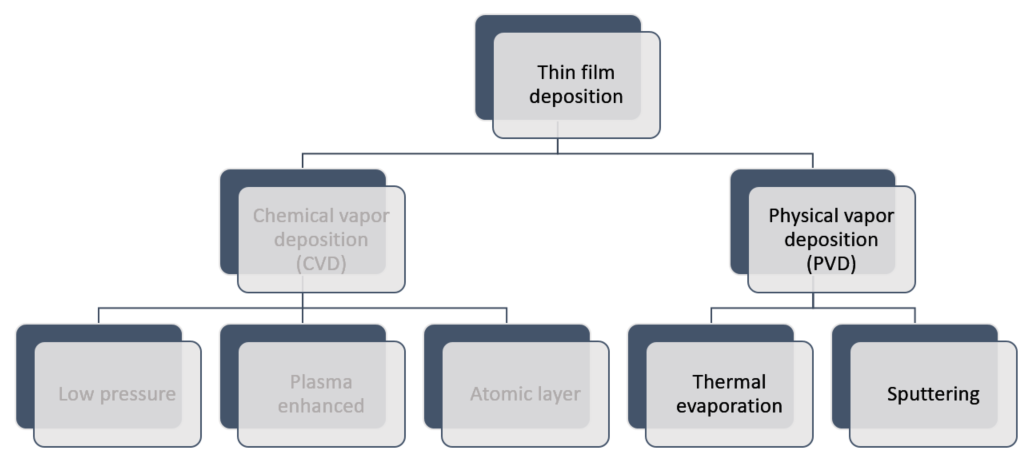

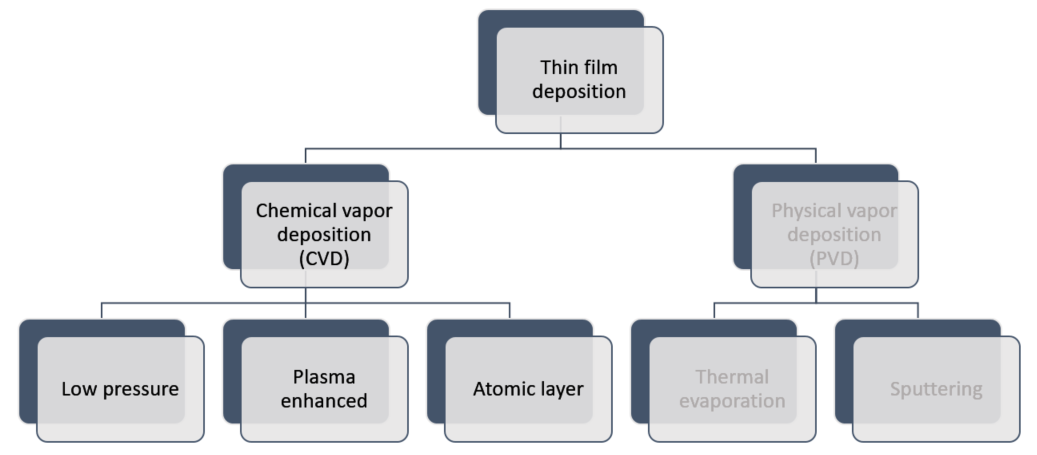

While many deposition techniques exist, this article focuses on those shown in Figure 1, namely PVD and CVD.

Physical vapor deposition (PVD)

As the name suggests, physical vapor deposition relies on a physical process to deposit thin films. The target material is first vaporized from a solid form into plasma or ions. Subsequently, it moves to the substrate surface, where it condenses and grows into a film.

Thermal evaporation

Thermal evaporation uses thermal energy from a tungsten heating element or an electron beam to vaporize the target material. After vaporization, the material passes through a high-pressure vacuum (1 x 10‑6 to 1 x 10‑9 Torr) and deposits onto the substrate, where it condenses into a solid film.

This method typically deposits pure metals, oxides, nitrides, and non-metals. Notably, it is used to deposit electrically conductive metallic layers on solar cells, OLED displays, and thin‑film transistors.

Sputtering deposition

Sputtering deposition transfers ions from a target material onto a substrate material using plasma, often argon, in a vacuum chamber (0 – 0.03 Torr).

While sputtering deposition techniques vary, the core setup remains consistent. The target material connects to a negatively charged cathode, and the substrate connects to a positively charged anode. Free electrons accelerate toward the anode and collide with argon atoms, creating positively charged ions. These ions then accelerate toward the cathode and knock atoms loose from the target, which then settle on the substrate surface.

Sputtering deposition was first applied in computer hard disk production. Today, it is used extensively in integrated circuit processing, anti‑reflective and high-emissivity film coatings, cutting tools, and CD/DVD coating.

Chemical vapor deposition (CVD)

Chemical vapor deposition forms a thin film through a chemical reaction, usually involving a gaseous target material that reacts near the substrate. CVD processes use mass flow controllers to introduce precise amounts of gas reactants to a process chamber. These reactants travel to the substrate surface, where the desired chemical reaction takes place. Afterward, by-products are removed.

Low pressure chemical vapor deposition (LPCVD)

Low pressure chemical vapor deposition (LPCVD) operates at 0.1–10 Torr and 200–800 °C. Reactants enter the chamber via a showerhead system, while the chamber walls remain cool and the substrate is heated. This setup encourages heterogeneous surface reactions. Once the reaction completes, the by‑products exit using vacuum pumps.

LPCVD is often used to produce resistors, capacitor dielectrics, MEMS, and anti‑reflective coatings.

Plasma enhanced chemical vapor deposition (PECVD)

Plasma enhanced chemical vapor deposition uses plasma to provide the energy required to facilitate the chemical reaction that drives the deposition. Electrical energy creates this neutral gas plasma. PECVD is performed at 2 – 10 Torr and relatively low temperatures from 200 – 400°C.

PECVD is widely used in the production of solar cells and microelectronics. Importantly, because PECVD works at lower temperatures, it is suitable for substrates that can’t withstand the high heat of other techniques.

Atomic layer deposition (ALD)

Atomic layer deposition generally employs two precursors that react with the substrate surface sequentially. The thin film is deposited by alternating the precursors fed into the chamber. Consequently, this allows the user to deposit the desired thin film layer by layer and offers superior control over film thickness.

ALD is commonly used in microelectronics fabrication. For example, applications include magnetic recording heads, MOSFET gate stacks, DRAM capacitors, and nonvolatile ferroelectric memories. It is also used to enhance the surface properties of implantable biomedical devices.

Conclusion

Choosing the right thin film deposition method ultimately depends on your process requirements. Therefore, understanding these techniques helps you select the best option to maximize coating quality and throughput.

With a 10 ms response time, accuracy as good as 0.5% of reading, and the ability to integrate easily into your pre‑existing setup, Alicat’s MCE or MCV‑Series mass flow controllers enable the production of high quality, repeatable coatings across a variety of deposition setups.