Laminar Differential Pressure (DP) Flow Meter – Operating Principle

Differential pressure flow meters measure flow by monitoring the pressure drop across a restriction in the flow path. In 1992, Alicat® Scientific pioneered the use of laminar differential pressure (DP) flow measurement, a more precise method that forces turbulent flow into laminar flow before measurement. This innovation improved the accuracy, speed, and stability of differential pressure technology and today powers thousands of Alicat flow meters and flow controllers used worldwide.

The physics behind laminar differential pressure flow measurement

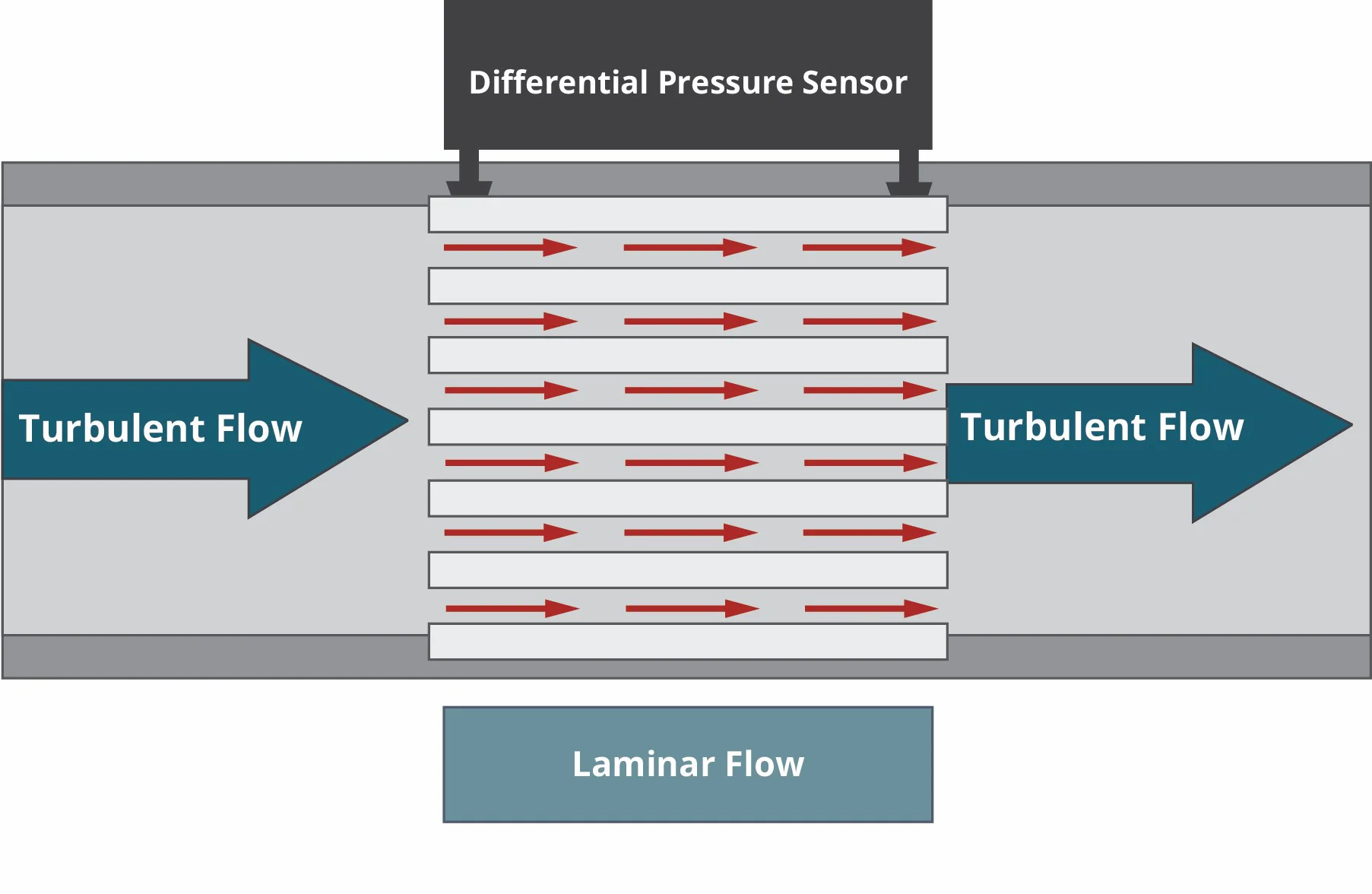

When fluids move through a pipe, they can flow turbulently or laminarly. In a turbulent regime, flow is chaotic and unpredictable, but in a laminar regime, flow moves in smooth, parallel layers.

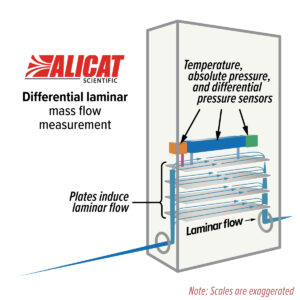

Alicat laminar DP flow meters and laminar DP flow controllers contain a flow passage called a laminar flow element (LFE) that converts all turbulent flow into laminar flow. The instrument first measures the differential pressure drop across the LFE and then uses the Poiseuille Equation to calculate a volumetric flow rate.

This principle allows DP-based instruments to calculate flow with high precision when paired with pressure and temperature sensors.

How laminar DP flow meters measure mass flow

Step 1. Flow conversion

Step 2. Differential pressure and sensor measurement

A differential pressure sensor measures the pressure drop across the LFE, while absolute pressure and temperature sensors capture real-time conditions inside the flow channel.

Step 3. Volumetric flow calculation

Using the Poiseuille equation, the instrument calculates a volumetric flow rate from the measured pressure drop and fluid viscosity.

Poiseuille equation

Volumetric flow = (P1-P2)πr4/8ηL = K(ΔP)/η

P1 = Static pressure at the inlet; P2 = Static pressure at the outlet; r = Hydraulic radius of the restriction;

η = Absolute viscosity of the fluid; L = Length of the restriction

The Poiseuille equation shows the linear relationship between volumetric flow rate, differential pressure (ΔP), and absolute viscosity (η). In the simplified equation, K is a constant that encompasses the geometric factors of the LFE.

Step 4. Mass flow calculation

The system then applies density correction factors for temperature, pressure, and compressibility to calculate the standardized mass flow rate:

Density correction factors

1. Temperature density correction = Ts/Ta

Ta = Absolute temperature at flow conditions; Ts = Absolute temperature at standard conditions (STP)

2. Pressure density correction= Pa/Ps

Pa = Absolute pressure at flow conditions; Ps = Absolute pressure at standard conditions (STP)

3. Compressibility = Zs/Za

Za = Compressibility at flow conditions; Zs = Compressibility at standard conditions (STP)

When combined, you can produce an equation that uses volumetric flow, temperature, pressure, and gas compressibility to calculate a mass flow rate.

Mass flow rate equation

Mass flow = (Volumetric flow)(Ts/Ta)(Pa/Ps)(Zs/Za)

(Ts/Ta)(Pa/Ps)(Zs/Za) = Density correction factors

How laminar DP flow measurement works

Applications of laminar differential pressure devices

Laminar DP flow technology powers a wide range of Alicat instruments, including mass flow meters, mass flow controllers, liquid flow devices, and pressure measurement and control instruments. Because this technology combines speed, accuracy, and versatility, its applications span from laboratory research to industrial process control. Examples include:

Gas chromatography (GC)

Alicat Mass Flow Controller (MC) and Pressure Controller (PC) ensure stable carrier and sample gas control in gas chromatography systems, improving repeatability and simplifying calibration.

Bioreactors & bioprocessing

Alicat mass flow controllers (MC) enable precise oxygen and air delivery in bioreactors, with controllable ranges up to 10,000:1 that reduce system complexity and costs.

Leak testing & aerospace

In rocket engine valve leak test stands, Alicat pressure controllers (PC up to 3,000 PSI) and Whisper low-pressure drop flow meters (MW) ensure accurate, repeatable leak detection.

Frequently asked questions about laminar DP flow meters

How do laminar DP flow meters work?

They measure mass flow in four steps: convert turbulent flow to laminar, measure the pressure drop, calculate volumetric flow, and convert to standardized mass flow.

What is the difference between mass flow and volumetric flow?

- Volumetric flow measures the physical volume of a fluid moving through a system (e.g., liters per minute).

- Mass flow quantifies the actual number of molecules moving per unit time, independent of temperature and pressure changes.

Read more in our Mass vs. Volumetric Flow Guide.

How to choose the right mass flow meter technology?

Accurate measurement and control of fluid flow are critical across many industries and research fields. At Alicat Scientific, we offer three complementary mass flow technologies: Laminar Differential Pressure, Coriolis (CODA), and Thermal MEMS (Basis).

Each technology provides unique advantages:

- Laminar DP: Ultra-fast response, multi-gas compatibility, low pressure drop.

- Coriolis: Direct mass measurement, excellent for unknown or mixed fluids, and density measurement.

- Thermal MEMS: Compact, cost-effective, ideal for embedded OEM and basic gas applications.

To help you decide, compare specifications in our Flow Technology Comparison Table.