Coriolis Flow Meter – Operating Principle

The Coriolis flow meter principle technology measures mass flow directly by detecting tiny deflections in a vibrating tube. This page explains the Coriolis effect, shows how it works in mass flow measurement, and reveals why CODA devices excel in precision applications.

The physics behind the Coriolis flow meter principle

The Coriolis effect is commonly used to explain why hurricanes, tornadoes, and typhoons spin clockwise in the Southern Hemisphere and counterclockwise in the Northern Hemisphere. The frictional Coriolis force causes this phenomenon. It deflects objects moving within a rotating frame of reference. In this weather example, air travels through the atmosphere and shifts right or left depending on the hemisphere. This shift determines the spin direction of weather bodies.

While Newtonian laws of motion describe how objects move in a stationary frame, motion in a rotating frame requires an additional correction factor. This factor, known as the fictitious Coriolis force, accounts for the apparent deflection observed in such systems. This is necessary because the object isn’t physically tethered to the frame of reference, or coordinate system, which is used to characterize its motion. The rotating frame of reference makes the object appear to deflect from its original path.

The difference between the intended and actual path is measurable as a deflection resulting from the Coriolis effect. A real-world example to help explain: Imagine that a person calculates a ball trajectory using only Newtonian laws. The person then stands at a spot near the North Pole and launches the ball directly south towards a target on the equator. If the Earth were a perfectly still, stationary frame of reference, the ball would land on the target. But since the Earth is spinning, the ball actually lands somewhere to the west of the target. The magnitude of this westward deflection increases the longer the ball is in the air and the closer it is to the equator.

Other mass flow measurement principles, such as thermal or laminar DP, calculate mass flow rates using measured temperature change or volumetric flow values in conjunction with known fluid properties. Flow meters and controllers, using the Coriolis principle, measure mass flow directly without depending on fluid properties. This is made possible by a clever utilization of the Coriolis effect.

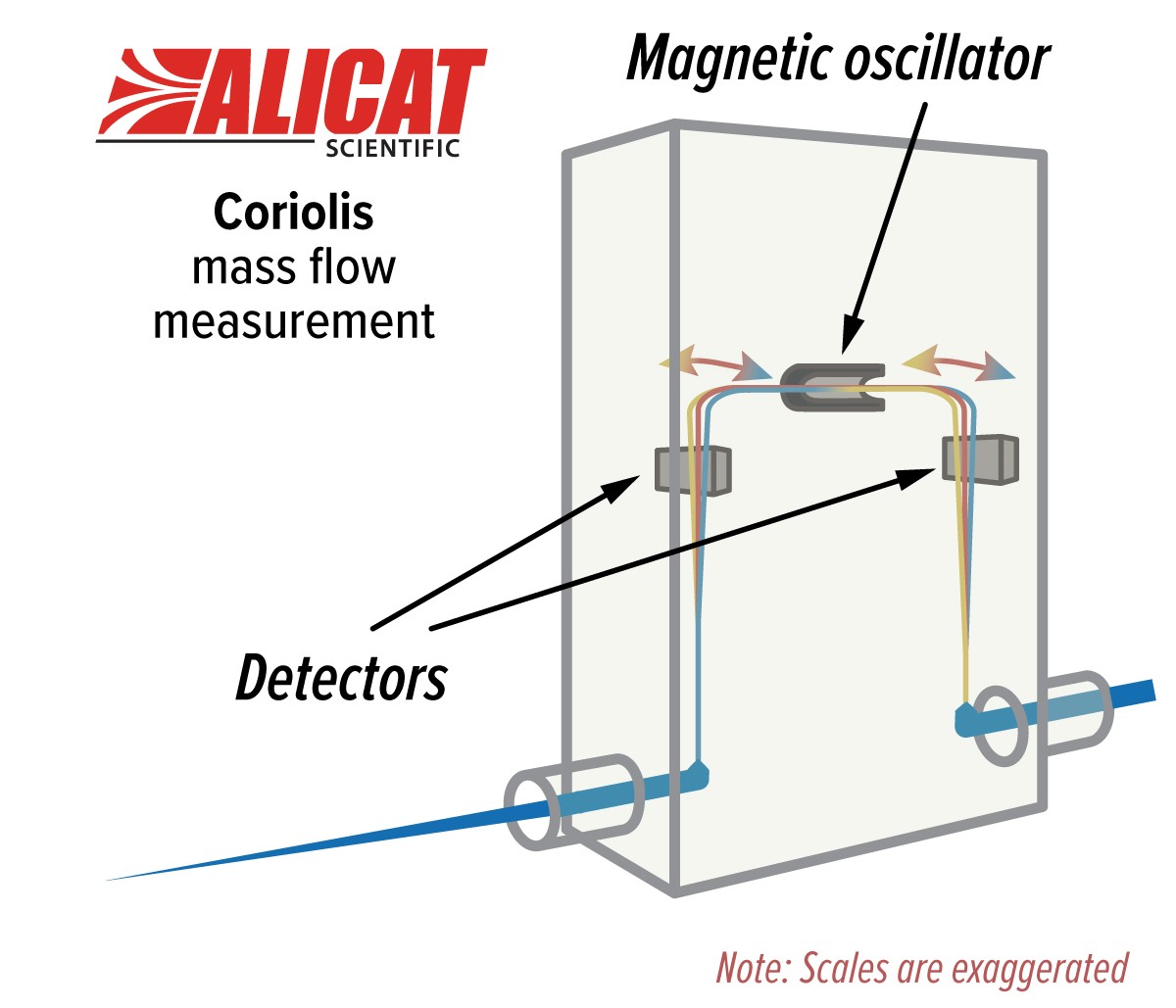

How Coriolis flow meters accurately measure mass flow

A tube (or a set of tubes) is electromagnetically actuated and functions as a moving frame of reference. All fluid entering the device travels through the moving tube and experiences a very tiny deflection from its intended path. Sensors measure the magnitude of the deflection as a vibrational phase shift between different points in the tube. The deflection depends only on the fluid’s mass. This allows Coriolis instruments to measure mass flow precisely, regardless of fluid properties, composition, or temperature. A single temperature sensor measures the tube’s temperature because its physical properties can change slightly depending on temperature. This reading ensures the instrument maintains precise measurement under varying conditions.

Coriolis flow meters can vary greatly in size, with tube diameters as small as a few millimeters and as large as 30 millimeters.

Why CODA™ low flow Coriolis flow meters stand out

Alicat® CODA Coriolis mass flow meters and CODA Coriolis mass flow controllers for gases, as well as CODA meters for liquids and CODA liquid flow controllers, are miniaturized Coriolis instruments for low-flow applications. They cover a wide range of lower flows, from 8 g/hr to 300 kg/hr. They work reliably with unknown gases and liquids.

CODA devices measure mass flow, density, and temperature simultaneously. So they can compensate for changes in these conditions and remain accurate, while reporting multivariate information to you. You see your reported data on the programming display on the front, through digital communications, or over analog feed. Alicat’s Coriolis devices have robust vibration tolerance without excessive weight, and can operate well in noisy environments that disrupt other miniaturized Coriolis instruments.

This video demonstrates the measurement process and shows how the Coriolis flow meter principle delivers unmatched precision in CODA instruments.

CODA low flow Coriolis applications & latest innovations

Fuel cell testing

When process conditions include high pressures and low flow rates, a CODA Coriolis mass flow controller offers a reliable, high-accuracy solution.

Low-flow color dosing

CODA Coriolis flow meters deliver repeatable, precise mass flow readings for low‑flow liquids and gases. Integrated into color dosing systems, they provide real‑time feedback to pumps, ensuring consistent dosing, reduced waste, and process repeatability.

Slot-die coating optimization

In precision coating applications such as OLED, battery manufacturing, or solar panel production, CODA Coriolis mass flow controllers ensure stable, accurate flow rates, up to ± 0.2% of reading, even for fluids of unknown composition. This guarantees predictable, uniform coating thicknesses.