Rocket Propulsion System Validation with Precision Gas Mixing

How gas mixing powers rocket propulsion testing

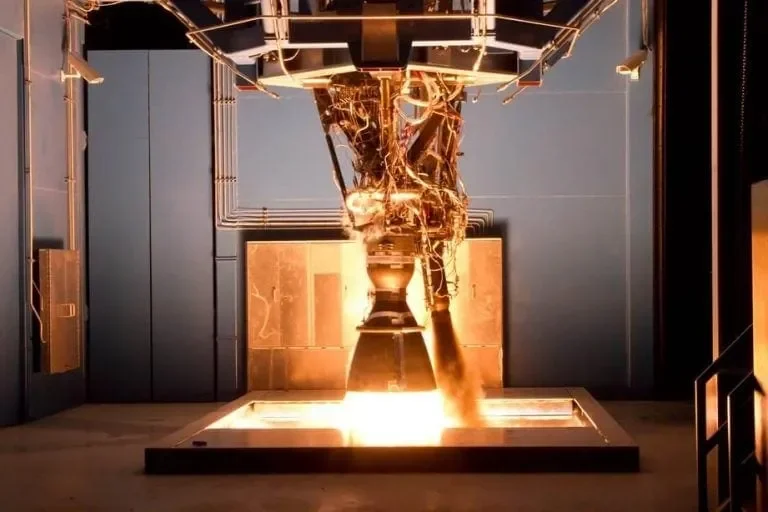

Rocket propulsion test labs recreate a wide range of atmospheric and engine conditions to understand how engines behave under changing loads, altitudes, and fuel blends. In these labs, controlling gas mixtures is directly responsible for helping researchers determine critical mission variables. Accurate blends of combustible, and carrier gases allow engineers to simulate flame temperature, ignition stability, injector performance, and exhaust chemistry far before any of the rockets launch, making it a foundational step in the process.

Because propulsion testing is extraordinarily sensitive, even small shifts in gas composition can distort results. A precise mixing system allows propulsion teams to diagnose real problems and make mission-critical decisions based on trustworthy lab results.

Challenge

Because of how rigorous fuel-blend test regimes must be, two challenges emerge immediately:

- How do you repeatedly combust large volumes of fuel at an affordable cost?

- How do you maintain accurate, repeatable gas compositions without constant recalibration or bottle changes?

Test engineers working at a rocket propulsion research facility faced these questions when they determined their setup would require a gas mixing platform capable of blending several combustible gases with precision and programmability.

This system would need to:

- Continuously deliver time-varied compositions during transient runs

- Account for unique combinations of oxygen, nitrogen, hydrogen, and methane

- Maintain tight ratio control, even as total flow, pressure, and downstream processes changed

- Integrate into a pre-existing lab environment with minimal manual intervention, and minimal downtime between tests

Options

Static, manual, and premixed sources

When considering their options, the engineering team evaluated several approaches:

Premixed cylinders

- Premixed cylinders are simple to deploy and offer known fixed ratios, but they limit flexibility. Any change in test conditions requires swapping. Sitting cylinders can take up space, require specialized disposal procedures, and risk gas stratification over time in some cases

Manual blending panels

- Manual blending panels rely on needle valves, rotameters, and operator adjustment to set flow ratios. They can produce acceptable fixed mixtures, generally at a lower cost-point, but they do not provide closed-loop control, digital feedback, or active correction when downstream conditions change. Maintaining traceable accuracy over long test sequences would require frequent retuning, slowing down operations

Static gas mixers

- Simple electronic mixers reduce manual labor, but like cylinders, they have limited flexibility. Fixed-ratio mixers are unable to account for unexpected changes in composition, often have fewer channels, and in some systems require a separate tool for gas recalibration

None of these options fully met the facility’s combined requirements for precision, flexibility, rapid reconfiguration, and integration with an existing automated test stand.

Selection

All-in-one dynamic gas blending

To meet the facility’s requirements for precision, programmability, and multi-gas flexibility, the team selected an Alicat® Scientific FusionFlow™ MXM gas blender. The MXM provided closed-loop control across up to 10 independent channels, while providing continuously correcting flow to maintain target compositions. The MXM was an attractive option for its many features that allowed the team to run extended testing sessions with accuracy and confidence.

Closed loop multi-channel control

The MXM provides closed-loop control across all gas channels, using integrated Alicat mass flow controllers to maintain tight ratio accuracy during dynamic test profiles. Because each channel is regulated independently and corrected in real time, the system held mixture compositions even as total flow demand shifted. With precision down to ±0.6% of the targeted mix percentage and support for flows spanning 0 – 20 SCCM up to 0 – 120,000 SLPM (depending on configuration), the MXM offered the stability required for sensitive propulsion testing.

Programmable alarms and safety behavior

The MXM allowed the team to program step changes, ramps, and timed transitions between mixtures, enabling smooth composition shifts during complex test sequences. Built-in scheduling tools let researchers predefine full test profiles and alter ratios automatically while maintaining continuous flow. UEL and LEL safety features and alarms ensured each test ran smoothly, automatically shutting down if it surpassed the set boundaries.

Practical setup

The MXM fit cleanly into the lab’s existing setup with minimal rework. Researchers configured it to feed a ballast volume upstream of the test stand, smoothing pressure behavior during transient combustion cycles. An alternative rack-mounted form factor allowed easy repositioning as experiments moved between stations. Both the onboard touchscreen and browser-based controls simplified day-to-day use, allowing engineers to adjust mixtures or verify performance without interrupting a run.

Setup tips

Mixer setup features to check:

- Set the gas mixer to control pressure while measuring mass flow into a ballast volume for smooth control.

- Use high-quality tubing rated for all gas types.

- Reduce the chance of backflow, by ensuring all supply gases have a similar pressure at the mixer.

- Confirm compatibility of reactive or corrosive gases with the mixer’s manufacturer. The spec sheet should list all standard materials, and whether or not custom builds are available.

- For iterative testing, or to dynamically shift combustion mix during a test, use a mixer that has a dynamic scripting capability.

Outcomes

Supporting critical research

Because the MXM can operate across a wide dynamic range, the same system supported multiple test types—from low-flow ignition studies to higher-flow combustion experiments. Similar MXM configurations are already in use for cold-gas thruster work, bipropellant condition mapping, hybrid rocket development, and combustion-efficiency studies across both government and academic labs. Alicat Scientific instruments are trusted throughout the aerospace sector for mission-critical testing and control.

The future of aerospace research will depend on instrumentation that excels in connectivity, accuracy, and responsive control, giving rocket propulsion researchers the confidence to innovate without compromising precision.