Burner Testing with a Precision Gas Blender

Burner manufacturers and appliance producers are required to verify that their equipment operates safely, efficiently, and within emissions limits across the range of fuels it may encounter in the field. Certification bodies such as CSA establish testing protocols to confirm that burners maintain stable flame behavior, ignition reliability, and combustion characteristics under varying gas compositions and supply pressures.

Accurate testing depends on the ability to reproduce those fuel properties and flow conditions in a controlled environment. Each test must reflect the correct heating value, air-to-fuel ratio, and specific gravity of the target gas. Reliable results allow engineers and certifying agencies to evaluate burner performance and confirm compliance before products are released for commercial use.

Challenges in burner testing

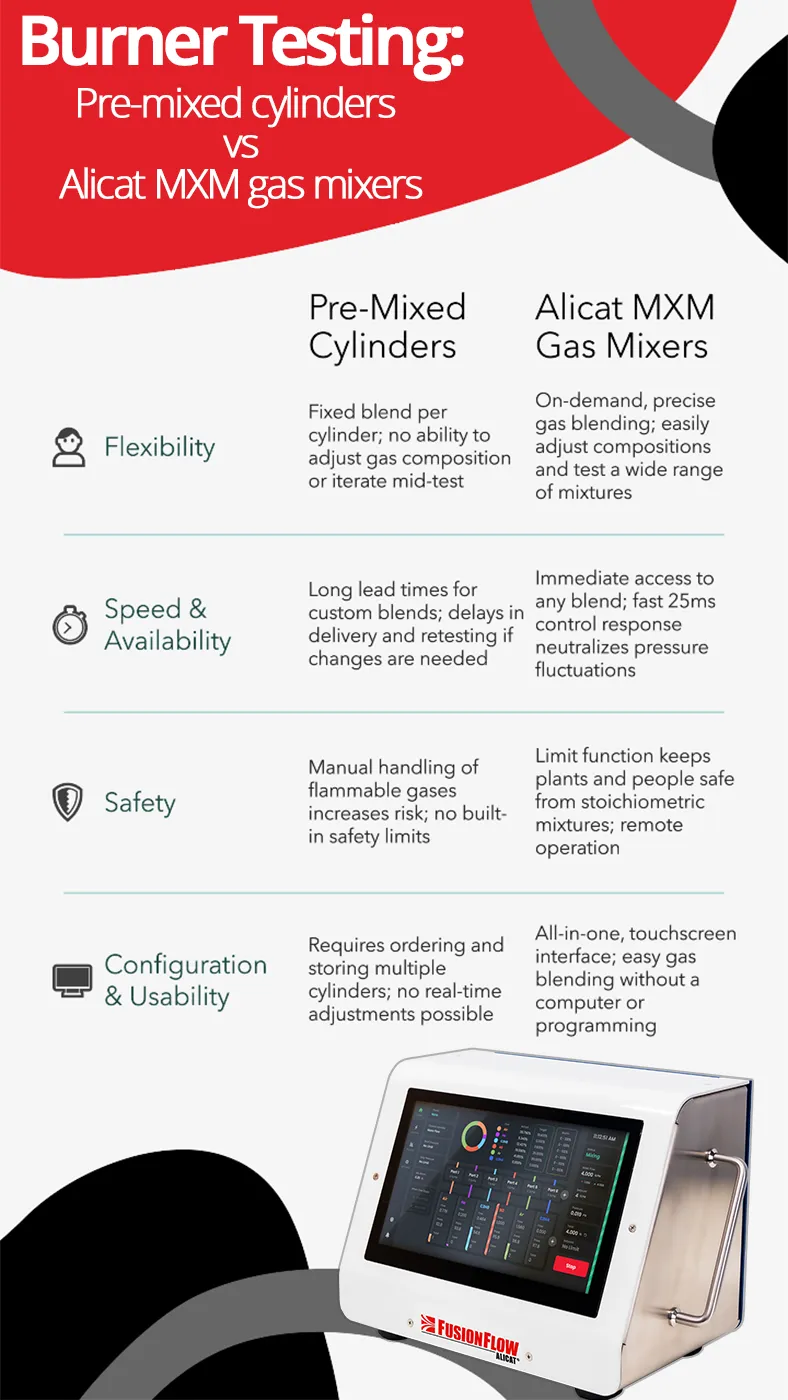

Appliance manufacturers and test facilities commonly use pre-mixed gas cylinders for burner evaluation. Cylinders provide a fixed blend that cannot be changed once delivered, which limits test flexibility. Each gas blend must be ordered separately, and empty cylinders accumulate quickly. Managing storage and disposal becomes a logistical burden that can add cost, administrative work, and unnecessary bulk in the test area while slowing down testing times.

During cyclic burner operation, supply-pressure changes can alter flow and mixture ratios at the burner. These variations affect flame shape, temperature, and emissions data, reducing test repeatability. Manual blending with rotameters or valves offers limited correction and increases both uncertainty in composition and operator exposure to gas.

Custom gas mixing for CSA certification

To maintain accurate mixture ratios during burner cycling, the MXM provided closed-loop composition control with automatic compensation for inlet and outlet pressure changes. The integrated Alicat mass flow controllers allowed researchers to quickly switch between test gases, with 25 ms control response and access to 49 selectable gas calibrations from an onboard library.

Safety limits within the system prevented stoichiometric or otherwise unsafe mixtures. Remote configuration allowed operation from outside the test area, minimizing handling of fuel gases and simplifying setup during certification runs.

The MXM’s interactive HMI displayed real-time flow, pressure, and blend composition. Engineers could adjust setpoints, monitor stability, and log performance data directly through the interface. Its compact, modular layout fit easily on existing test benches or carts commonly used in burner validation.

With the MXM in place, the team produced custom gas blends on demand, adjusted mixture ratios between test points, and maintained stable flow throughout repeated test cycles. Inline analyzers verified composition accuracy, and flame characteristics confirmed consistent burner operation across all test conditions.

Observed Results

- Stable flow maintained during burner cycling

- No measurable drift over multiple days of continuous operation

- Blend accuracy confirmed by gas analysis and flame behavior

- Safe remote operation with automatic mixture protection

Summary

Precise gas control is essential for reliable burner testing. Stable mixture ratios allow engineers to compare burner behavior across multiple operating conditions without interference from gas-supply variability.

Using FusionFlow MXM, fuel composition and flow remained constant during repeated test cycles. The closed-loop system eliminated drift and flow imbalance often seen with pre-mixed cylinders or manual blending. Consistent test conditions produced repeatable flame and emissions data suitable for certification review.