Keeping Ethylene Samples Stable in Steam Cracking

Maintaining efficiency and safety in a steam-cracking operation depends on tight control across every stage—from furnace temperature and quench timing to gas separation and recovery. Analyzer sampling loops are a critical part of that control. These small, conditioned streams feed gas chromatographs (GCs), Wobbe index analyzers, and oxygen detectors, delivering the data operators use to tune furnace severity, monitor coking, and maintain safe, efficient operation.

The challenge

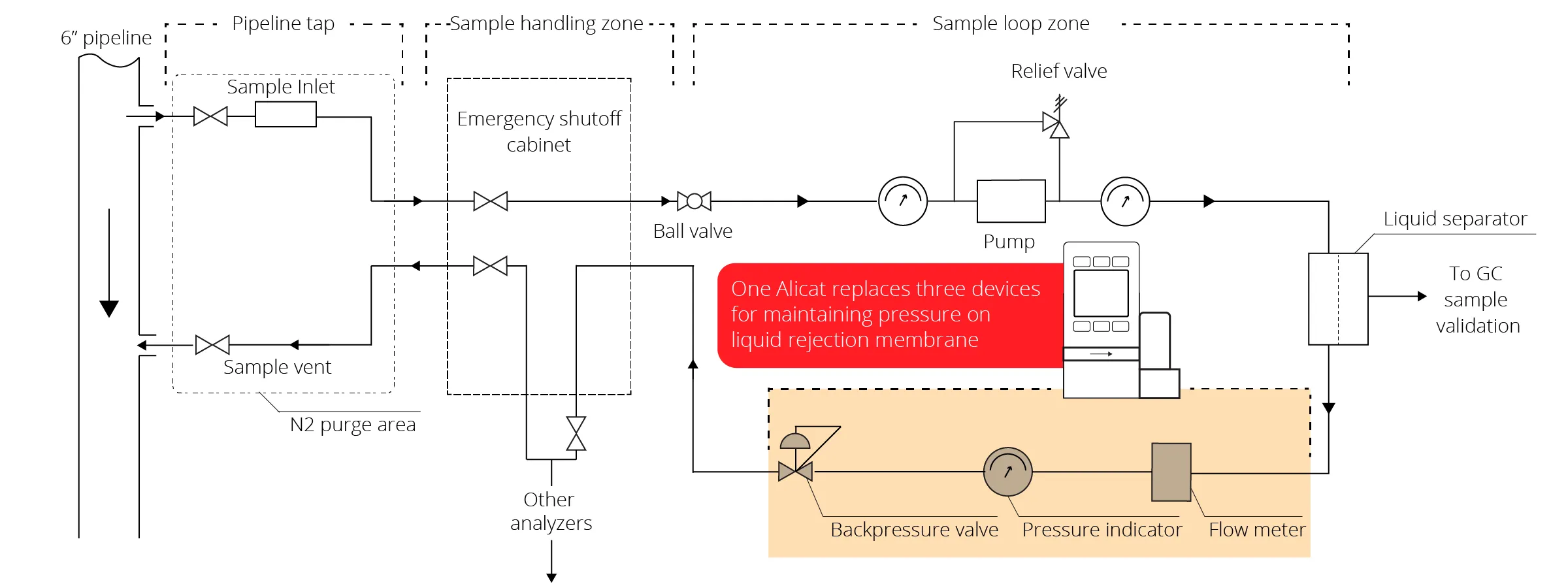

Each analyzer performed a distinct role within the system, making it essential to select instrumentation that could satisfy all their operational requirements simultaneously:

- The liquid rejection membrane needed stable backpressure to prevent collapse and maintain filtration efficiency.

- The oxygen analyzer required precise flow and cell pressure to prevent drift in its readings.

- The gas chromatograph depended on consistent split ratios and stable backpressure; otherwise, retention times and peak clarity could fluctuate with changes in ambient pressure or downstream venting.

- The Wobbe index analyzer required steady balance-loop pressure to ensure accurate combustion-quality calculations.

Without dependable flow and pressure control at each point, these loops risked inconsistent sampling, unreliable analyzer data, and poor furnace optimization.

Smarter options for modern sampling

The membrane loop holds stable pressure downstream of the compression pump with a single IS‑Max. The oxygen analyzer maintains steady purge and cell pressure from one device instead of several. The GC benefits from automatic backpressure control, keeping split ratios constant without seasonal rebalancing. The Wobbe analyzer verifies balance-loop pressure digitally through an IS‑Pro, logging real-time data for operators.

Cleaner data, safer operation

By consolidating instruments and integrating digital control, the sampling system became both simpler and more stable. Analyzer readings stopped drifting, membrane performance stayed consistent, and the overall loop required less technician intervention in hazardous zones.

With continuous digital communication feeding flow, pressure, temperature, humidity, and totalized volume directly into the DCS, operators gained a complete record of sample conditions. They could see and trust the data that guided furnace optimization and compliance reporting.

The outcome was straightforward but significant: fewer devices, fewer leak points, steadier analyzers, and cleaner data. For a process as fast and unforgiving as ethylene cracking, that stability translates directly into better yield, safer operation, and measurable efficiency gains.

As ethylene production continues to expand globally, the systems that support it must evolve just as quickly. Reliable analyzer sampling ensures safety, optimal production, and emissions compliance. By pairing proven control principles with intrinsically safe digital instruments, operators can modernize without sacrificing dependability. The result is cleaner data, safer operation, and a stronger foundation for the future of petrochemical processing.