Industries

Whether leak testing space vehicle parts, dynamically regulating flows into banks of bioreactors, or environmental monitoring of explosive gases at a well cap, our devices help every person in the system, from process designers to maintenance technicians, do their work quickly, successfully and in thorough control.

Professionals from all industries select our products for their comprehensive data collection, versatility, and ease of use. And they love us for our responsive and informed product support.

Don’t see your industry below?

Contact us to see how we can help.

Jump to an industry

Aerospace & defense

Bioreactors & fermenters

Calibration & metrology

Environmental & air monitoring

Environmental & air monitoring

Food & beverage

Gas chromatography

Gas mixing

Glass & Optical Fiber

Glass & Optical Fiber

Hydrogen

Lab grown diamonds

Leak testing

Leak testing

Research laboratories

Thin film deposition

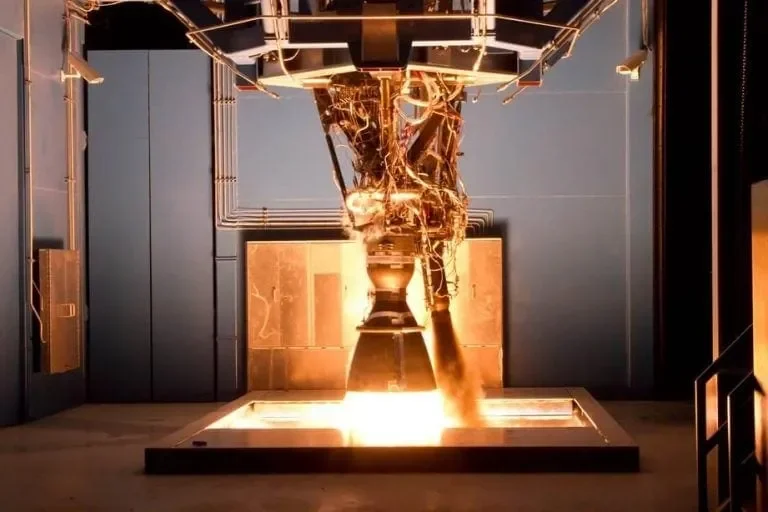

Aerospace and defense

Manufacture and test mission-critical components and systems

Find our instruments in thruster test stations, environment control systems, exotic atmosphere simulations, or handling coolants. Alicat supports your manufacturing and validation testing for space and flight.

Use cases:

- Characterize flow, and leak test, valves and thrusters

- Breathing simulation

- Space suit leak checking

Bioreactors and fermenters

Fine tune, automate, and scale bioreactor and fermentation systems

Use cases:

- Back pressure control in scale out and scale down parallel fermentation processes

- Headspace monitoring for real-time control of culture growth

- Inflating single-use bioreactor bags using dual‑valve pressure controllers

Calibration and metrology

In-field and in-house calibration and metrology using portable transfer standards

Use cases:

- Wireless transfer standards used for in‑field calibration and verification without outlets, cables or computers

- Using multivariate meters to fully compensate for ambient conditions

- Calibration, validation, and verification with dependable accuracy, flexibility and durability

Environmental and air monitoring

Measure and analyze ambient air quality and industrial emissions

Use cases:

- Performing field audits to meet EPA, and CNEMC monitoring requirements of atmospheric methane emissions

- Operating at near‑atmospheric pressures to enable ambient air measurements

- Characterizing ozone production using mass flow control

Food and beverage

Process and package long-lasting food and beverage products

Use cases:

- Blanketing with gases mixed on site eliminates the need for expensive pre-mixed gases and enables easy traceability of all packaging elements

- Accurate, low-flow dosing ensures consistent introduction of additives, maintaining quality control

- Aeration, carbonation, or nitrogenation introduce the bubbles and creaminess customers crave

Gas chromatography

Optimizing and verifying gas chromatography processes

Use cases:

- Carrier gas flow

- GC flow calibration and verification

- Controlling back pressure to run GCs at higher internal pressure

Gas mixing

Customize and dynamically program in-house gas mixing

Use cases:

- Gas sensor testing and calibration

- Welding shield gas blending

- Modified Atmosphere Packaging

Glass and optical fiber

Fabricate high-purity preforms and draw low-loss glass and optical fiber

Use cases:

- Fuel and shield gas control for preform purity

- Furnace temperature control gases

- Automating glass blowing

Hydrogen

Regulating and control of electrolysis and fuel cell systems processes

Use cases:

- Electrolysis feed pressure, flow metering, totalizing H2 and O2

- Fuel cell production and testing optimization

- Hydrogen leak testing

- Novel CO2 hydrogenation processes

Lab grown diamonds

High-performance flow and pressure controllers designed for lab grown diamonds

Use cases:

- Controlling mixes of hydrogen, methane, and carrier gas for diamonds

- Pressure control of vacuum plenum and deposition chambers

Leak testing

Faster leak testing with accurate leak rate measurement

Use cases:

- Fast accurate leak testing using flow

- Pressure decay testing the easy way

- Maintain pressure while measuring flow with one device

Oil & gas

Streamline petrochemical analysis and automate system pressure control

Alicat ticks all the boxes.

- Intrinsically safe, no explosion proof housings

- Automation reducing risk in hazardous zones

- Great for DLPRs or piloting other industrial pressure controllers

Use cases:

- Piloting DLPRs for pressure vessels, natural gas lines, etc.

- CEMS at well sites or processing facilities

- Sample conditioning & analysis: backpressure control for gas chromatographs, liquid rejection membranes & more

Research laboratories

Scientific discoveries and technological developments begin in the lab

Use cases:

- Closed-volume pressure control

- Atmospheric chemistry research

- Sensor development and testing

Thin film deposition

Optimize thin film deposition setups for maximum throughput and film quality

Use cases:

- Upgrade reactive sputtering systems

- Gas switching into film processes

- Faster vacuum stability