MXM-TK Benchtop Turnkey

All-in-one 6‑channel mixer for low to medium flow applications

- Table-top gas blending in one box

- 2 to 6 integrated MFCs, where any can be from 0 – 100 SCCM to 0 – 100 SLPM units

- 9.2” x 14.0” x 14.2” powder-coated chassis with stainless-steel flow path

MXM-MINI Benchtop Turnkey

All-in-one 6‑channel mixer for low flow applications

- A small form‑factor version of the turnkey MXM, for low flow applications

- 2 to 6 integrated MFCs, where any can be from 0 – 10 SCCM to 0 – 10 SLPM units (non-corrosive gases only)

- Full rear panel connectivity for all gases and connections

- 9.2” x 11.7” x 7.3” powder‑coated chassis with aluminum flow path

MXM-SA Benchtop Remote

Open form‑factor 10‑channel mixer for all flow applications (table‑top)

- Remote control interface box

- 2 to 10 onboard MFCs, where any can be from 0 – 100 SCCM to 0 – 12,000 SLPM units

- Fixed flow applications and dynamic pressure control for added range

- 9.2” x 11.7” x 7.3” compact table-top controller

MXM-RM Rackmount Remote

Open form-factor 10‑channel mixer for all flow applications (rack mount)

- An industrial form‑factor that includes all the same features and capabilities of the benchtop remote MXM

- 2 to 10 onboard MFCs, where any can be from 0 – 100 SCCM to 0 – 12,000 SLPM units

- 19” 4U rack space, steel chassis, rear pressure ports

Recommended Minimum Flow Rate for Individual MFCs

0 – 200 SCCM to 0 – 5 SLPM MFCs: 50 SCCM

0 – 10 SLPM to 0 – 100 SLPM MFCs: 1% of full scale

0 – 250 SLPM to 0 – 12,000 SLPM MFCs: 2% of full scale (remote form‑factors only)

Build Features

Export all gas mixer data to .CSV files, MySQL, PostGres, MSSQL, or Microsoft Azure cloud

Integrated scripting, scheduling, and event handling system

1280 x 720 resolution, 500 cd/m^2 brightness, 170 degree viewing angle

2 x USB 3.0

1 X RJ45 Gigabit Ethernet

24 v DC

Service port

Outboard controllers

Remote form-factors: 1/8” compression tube bulkhead fittings on rear panel

Mini Turnkey form-factor: 1/8” Female NPT on rear panel

For explosive environments, see the IS-Max™ Series

Ready for the final details?

Each product is made-to-order. Alicat’s Applications Engineers are ready to provide expertise and discuss custom options, ensuring the best fit for your needs.

Add-ons + Accessories

Digital I/O Module

USB-powered digital I/O module with 4 inputs / 4 outputs

Static Mixing Tubes

Stainless steel static mixing tubes in various lengths and diameters

Analog I/O Module

USB-powered analog I/O module with 4 inputs / 2 outputs

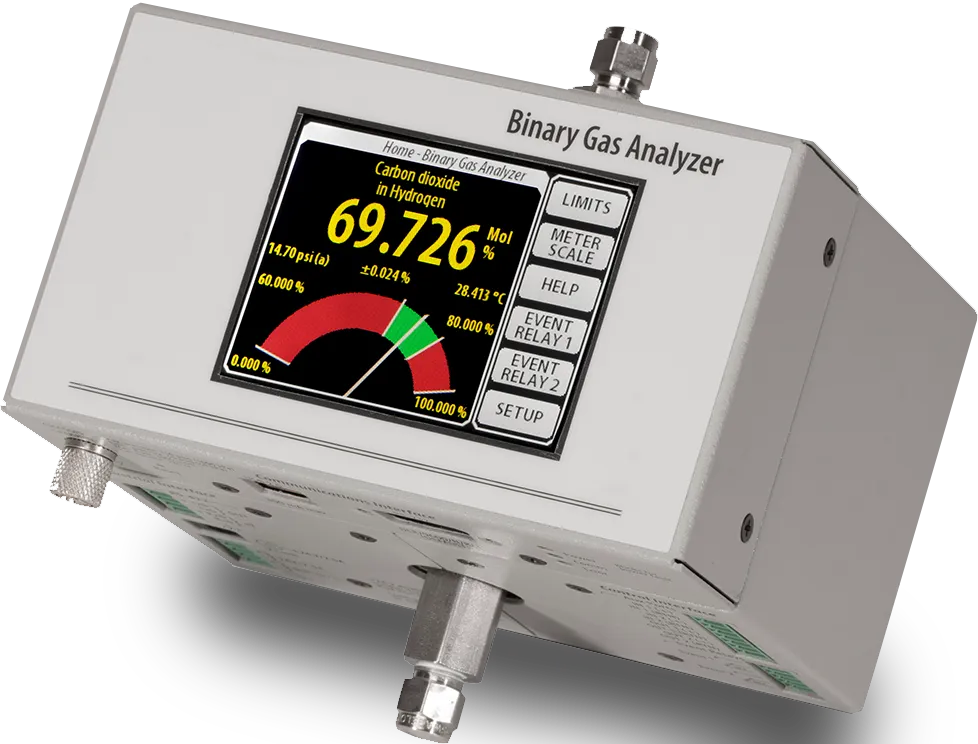

Binary Gas Analyzer

High-accuracy binary gas analyzer for 2‑gas blends

Ballast Cylinders

Stainless steel ballast cylinders in 6 different sizes

Pelican Transit Case

Rugged and high‑quality Pelican cases custom‑fitted for MXM systems

Ask an engineer

Our Applications Engineers can answer your questions and help you find the best option.

Service and Support

Whether it is time for your instrument’s annual recalibration or your instrument needs a repair or upgrade, you can fill out the Service Request Form below, email us, call us, or start a live chat session to get the service process started.

Call us

+1 (888) 290-6060

Live chat

Ask us a question

Help near you

Find a local representative

Tech docs

Reference materials