Meet Mira: A hydrogen powered boat with an Alicat MCRQ mass flow controller

- ATEX Zone 2 IIC certification, requires minimal additional safety infrastructure.

- ± 1.0% accuracy of reading (or ± 0.2% of full scale)

- Upstream valve position, enables precise regulation of downstream feed pressure, supporting target values like the ~2.5 bar commonly seen in fuel cell stacks.

- 4 – 20 mA analog output for high-speed update rates (kHz range)

Applications and use cases

Advantages of electronic flow and pressure control for hydrogen PEM electrolysis and fuel cell testing.

From direct regulation of electrolysis and fuel cell system processes to test benches for membrane and catalyst verification, we provide process solutions so you can focus on creating a more sustainable future.

Use Alicats for:

- Electrolysis & fuel cell system pressure regulation

- Multi-gas control in fuel cell test stands

- Back pressure of hot-wet hydrogen from fuel cell stacks

Related articles

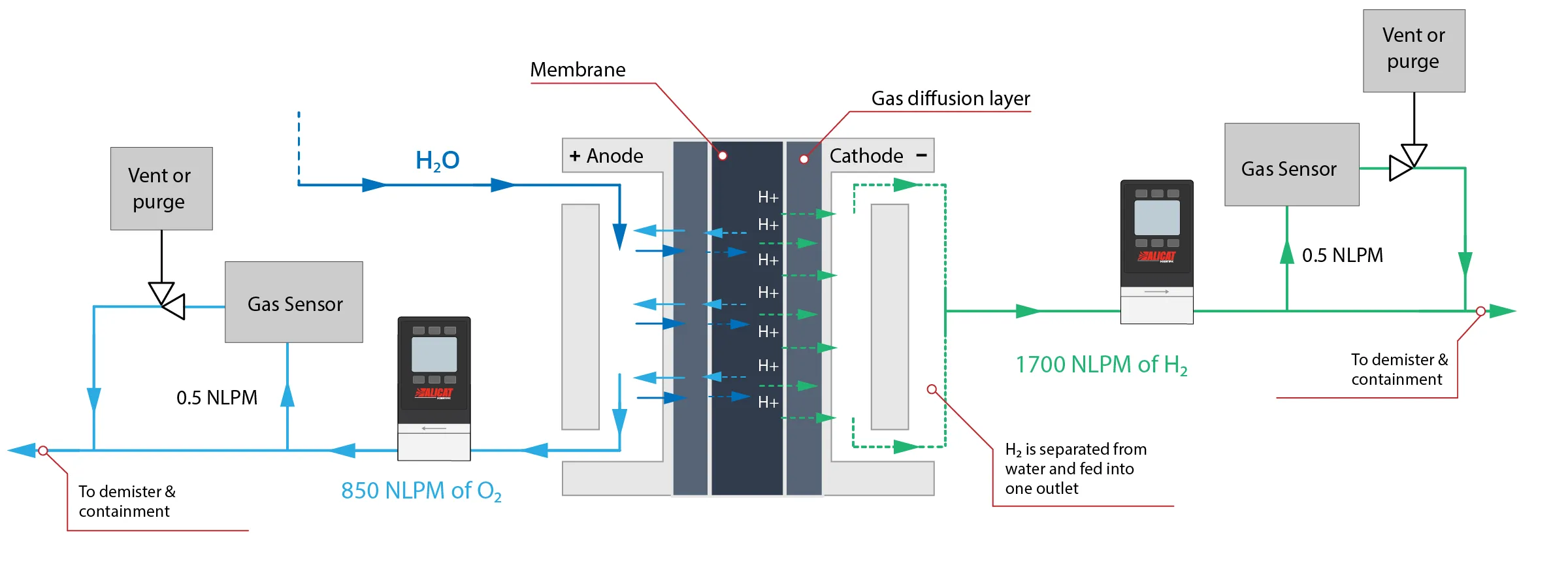

Safe PEM Electrolysis in Hazardous Zones

In water cracking operations using proton exchange membrane (PEM) electrolyzers, the close proximity of hydrogen and oxygen...

Liquid Hydrogen Fuel Systems for Marine Innovation

Figure 1: Mira at the official reveal. Hydro Motion Team’s 2025 liquid hydrogen-powered boat. The transition to sustainable...

Photoelectrocatalytic Water Splitting Research

The products of photosynthetic processes such as photocatalysis and CO2 reduction are motivating technological developments in...

Solar Hydrogen Electrolysis Systems

There are two primary ways to generate solar hydrogen: hydrogen produced from solar energy. The first is via a photochemical...

Related products

Ask an engineer

Your flow rate, pressure, and choice of gas can all affect which Alicat instruments work for your application.

Our Applications Engineers can answer your questions and help you find the best option.

Call us

+1 (888) 290-6060

Live chat

Ask us a question

Help near you

Find a local representative

Tech docs

Reference materials