Safe PEM Electrolysis in Hazardous Zones

In water cracking operations using proton exchange membrane (PEM) electrolyzers, the close proximity of hydrogen and oxygen requires continuous monitoring to maintain both safety and product purity. A certain degree of gas crossover through the PEM is unavoidable; therefore, labs track related indicators such as gas quality, energy efficiency, and production rate to verify that crossover remains within acceptable limits. If left unmonitored, membrane failure can occur, manifesting as water management imbalance, component degradation, or membrane pinholing, which may ultimately lead to stack failure.

To mitigate these risks, laboratories integrate analytic equipment capable of high‑precision measurement and strict safety compliance.

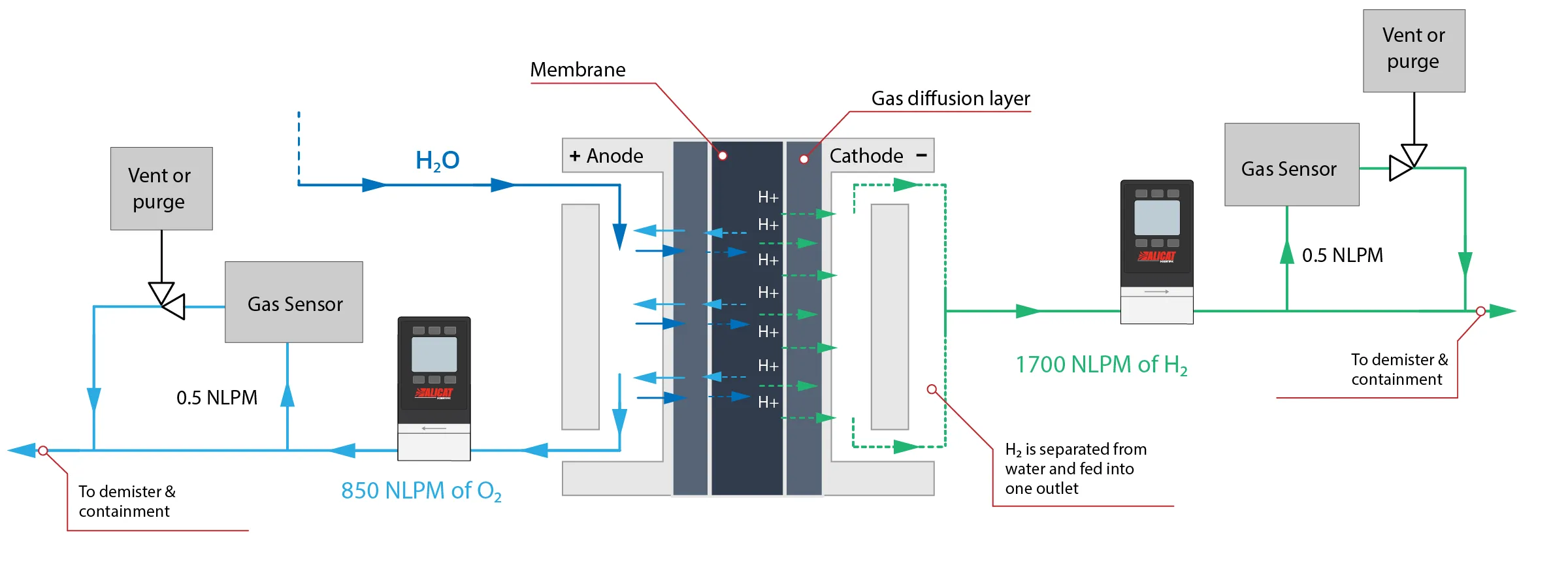

In a Class I, Division 2 (CID2) hydrogen lab, a PEM electrolyzer system was configured with meters to measure hydrogen and oxygen output, warning operators of any cross‑contamination. Each outlet was equipped with an Alicat® Scientific intrinsically safe IS‑MAX™ mass flow meter, with the anode side flowing up to 850 NLPM of oxygen and the cathode side up to 1700 NLPM of hydrogen. Downstream of the meters, both the hydrogen and oxygen lines diverted 0.5 NLPM into separate gas sensors to monitor crossover rate.

By placing the flow meters upstream of the sampling branch, researchers ensured that the purity sensors were working with a steady, well‑characterized gas stream. The meters established the actual production rate of hydrogen and oxygen before any side stream was drawn off, so the sample readings could be interpreted in context. This arrangement let the team determine if the crossover rate was expected for the flow, or if it signaled a deviation that could point to membrane wear or water imbalance.

Membrane degradation and catalyst corrosion

Proton exchange membrane performance can decline under low humidity or elevated temperature, conditions that accelerate ionomer degradation. Inadequate gas flow control or improper shutdown further compound the risks, leading to issues such as flooding or starvation—and in some electrolyzer designs, driving carbon corrosion in the catalyst supports. As the carbon oxidizes, conductivity decreases, catalyst particles detach, and the electrode‑membrane interface weakens. This makes the membrane more vulnerable to physical failure and gas crossover.

Accurate flow measurement is essential for preventing these problems. It confirms that reactant gases are supplied at the correct stoichiometry, minimizing the chance of hydrogen starvation or oxygen oversupply. It also enables operators to spot abnormal shifts in output that may indicate early‑stage corrosion or the onset of membrane pinholing, while long‑term trending helps track gradual degradation before irreversible damage occurs.

Although PEM systems are engineered to operate far outside of lower or upper explosive limits, localized mixing in sampling lines can create pockets where oxygen and hydrogen concentrations might fall within hazardous ranges. Even trace crossover beyond design limits reduces product purity, disrupts downstream processes, and signals potential water‑management or structural issues in the membrane. High‑accuracy, real‑time flow measurements make it possible to detect crossover well before concentrations approach dangerous thresholds. Early intervention allows operators to isolate an affected cell or shut down the stack in time, reducing both downtime and ignition risk.

Multivariate data capabilities

The IS‑MAX meter’s multivariate data reporting captures up to thirteen parameters, including mass and volumetric flow, temperature, absolute/gauge/barometric pressure, and relative humidity. Consolidating these measurements in a single ATEX‑, IECEx‑, and CID1‑compliant device reduces the need for separate barriers and enclosures, while streamlining maintenance in hazardous areas.

Additionally, the meter’s ability to read humidity and dew point serves as a helpful diagnostic tool for membrane health and overall water management. Abrupt changes in process humidity could reveal otherwise hidden facts about the membrane’s performance or hydration balance, prompting further inspection.

The meters’ laminar differential pressure sensing kept flow non‑turbulent, ensuring stability and repeatability across the full range. With flow repeatability of 0.2% of reading and ± 0.02% of full scale, and a sensor response time of < 1 ms, they could capture and trend short‑lived crossover exposure that slower devices might miss. Measuring upstream of the sampling system ensured that purity sensor readings were directly correlated to validated process conditions, improving confidence in system health assessments.

Hydrogen's greener future

Running PEM electrolyzers safely in hazardous areas depends on catching gas crossover before it goes above design limits. Flow meters measure how much hydrogen and oxygen are being produced, giving a baseline for purity sensors to compare against. This setup makes it possible to tell the difference between normal crossover and signs of problems like membrane wear, pinholes, or water imbalance.

High temperature, low humidity, or poor gas flow can damage the system further by causing carbon corrosion or ionomer breakdown. Measuring flow, pressure, and humidity helps keep the gases in the right balance, prevents starvation and flooding, and keeps the membrane and catalyst layers stable.

Using instruments that combine all of these measurements in a single, intrinsically safe package reduces equipment needs in hazardous zones and makes it easier to track system health over time. This leads to faster detection of faults, safer shutdowns, and less risk of dangerous hydrogen‑oxygen mixtures forming.

For the wider hydrogen industry, these tools are key to scaling up. As systems get larger and more common, precise monitoring helps keep efficiency high, downtime low, and operations in line with safety standards. Reliable methods for detecting crossover and checking water balance confirm that hydrogen can be produced safely and consistently, paving the path forward for a greener future.