Vent Flow Monitoring in Abandoned Wells

Orphaned and abandoned wells pose a risk for natural gas leaks, which may contaminate aquifers with methane and other hydrocarbons. To control natural gas mitigation from aging or structurally compromised wells, operators carry out plugging and abandonment (P&A) procedues to permanently seal wellbores and prevent fluid leakage.

Despite these safeguards, gas can still escape if seals fail or wellbore cement degrades. To detect leaks early, operators monitor well integrity using two key diagnostics: Surface Casing Pressure (SCP), which identifies pressure buildup in the annular space, and Surface Casing Vent Flow (SCVF), which detects gas actively venting from the casing. Together, these measurements provide a comprehensive view of well integrity over time, guiding decisions about pressure relief, re‑plugging, or other remediation efforts.

However, in some cases — such as wells with an open annulus, where the outermost casing is hydraulically connected to the surrounding formation — SCP may not develop even if gas is migrating. Unless the gas becomes trapped or encounters resistance, pressure won’t build. In these situations, SCVF may be the only observable sign of leakage, making it a critical indicator for gas detection.

Detecting pressure buildup through SCP becomes especially important when gas migration occurs in closed or partially restricted systems. While the relief mechanism itself may operate independently of instrument precision, the ability to detect even modest pressure increases early and reliably is crucial to prevent exceeding safety limits. Most well designs include a Maximum Allowable Annulus Surface Pressure (MAASP) — the highest pressure the casing system can safely withstand at the surface. This value can range from 2,500 psi to over 10,000 psi, depending on factors like casing strength, cement integrity, formation fracture pressure, and hardware constraints. To avoid casing damage or induced formation leaks, pressure relief protocols must be triggered well below this threshold.

Further complicating monitoring, especially in SCVF applications, is the effect of backpressure. Even a modest pressure drop across a flow meter can restrict venting, which can artificially lower measured flow rates, or push gas into alternate pathways. For accurate diagnosis and safe operation, a monitoring system must allow gas to flow freely without adding resistance — all while operating safely in hazardous environments and integrating with existing SCADA infrastructure.

Intrinsically safe monitoring

Monitoring surface casing pressure (SCP) and surface casing vent flow (SCVF) requires instrumentation that can operate reliably in hazardous environments. These areas—typically around the wellhead—are classified as Class I Division 1 or Zone 0 due to the presence of flammable gases. Traditional flow and pressure instruments often require explosion-proof enclosures and protected cabling to meet safety standards, which adds complexity to both system design and field deployment.

Alicat® Scientific’s IS-Max™ mass flow meters and IS-Pro™ pressure meters are designed for direct use in these environments, with ATEX, IECEx, and North American CID1 / Zone 0 hazardous location certifications. IS instruments meet intrinsic safety requirements, allowing operators to install them at the point of measurement without the need for expensive purging systems or explosion-proof housings. In outdoor or high-traffic areas, they should still be placed in a protective enclosure or sun shield to guard against physical impact and direct exposure to sunlight. Even with this basic protection, installation remains far simpler and more compact than traditional explosion-proof systems, making rapid deployment across multiple sites feasible.

Beyond safety compliance, the IS‑MAX also reduces system complexity by combining multiple measurements into a single instrument. It can simultaneously monitor mass flow, volumetric flow, absolute and gauge pressure, barometric pressure, gas temperature, relative humidity, and dew point. This multivariate capability eliminates the need for separate sensors for each variable, streamlining data acquisition. All parameters are measured in the same location and under the same conditions, improving consistency and reducing the chance of measurement discrepancies between instruments.

The meter provides accuracy up to ± 0.4% of reading or ± 0.2% of full scale, which is critical for detecting small changes in annular pressure or low‑volume vent flows. It supports industrial protocols such as MODBUS RTU and Alicat ASCII, as well as analog communications forintegration with SCADA or standalone logging systems. A built‑in display allows technicians to verify system status or review flow totals directly in the field, without requiring a seperate interface.

Case study 1: monitoring without telemetry infrastructure

An environmental monitor, responsible for measuring SCVF at a remote site, needed a CID1‑certified mass flow meter that could function without reliance on digital telemetry infrastructure. Because no SCADA system or serial communication network was available at the site, the operator selected an instrument that supported analog output for basic flow monitoring.

An Alicat IS‑MAX meter was deployed, configured to accommodate a flow rate of 50 SLPM at 15 °C and 2.3 bar. The instrument’s onboard digital flow totalizer displayed the total vented gas volume and elapsed monitoring time since the last reset, allowing field technicians to log precise measurements during site visits. In the absence of modern telemetry, the combination of analog output and local display ensured accurate, low‑complexity data collection and reporting.

Case study 2: low flow monitoring with minimal pressure drop

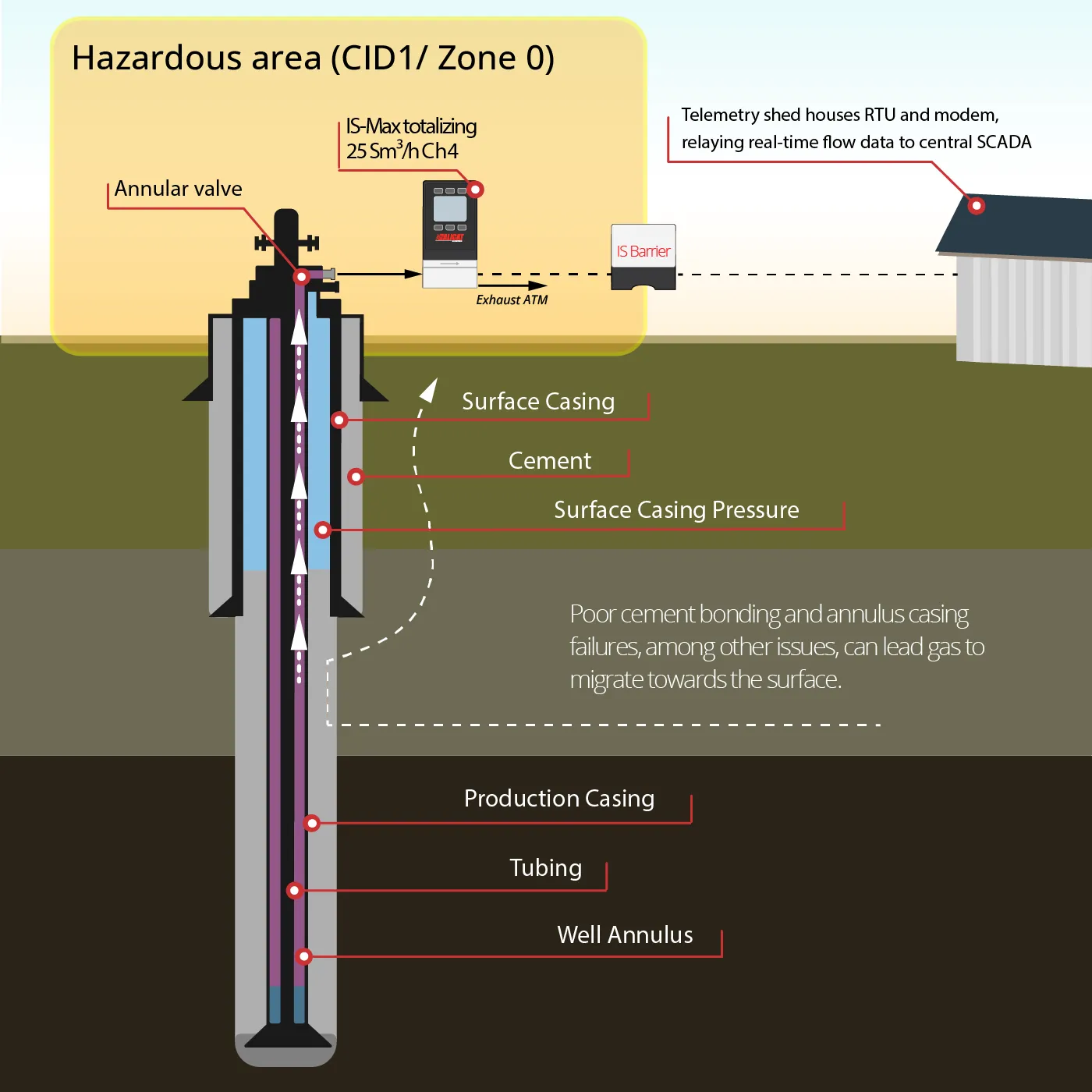

A North American gas producer required continuous monitoring of natural gas venting at 25 Sm³/h and pressures below 10 PSIG from a surface casing vent in a Class I, Division 2 environment. Traditional flow meters introduced excessive pressure drop, impeding natural flow from the annulus and reducing measurement accuracy — a key concern in monitoring surface casing vent flow (SCVF), which can indicate gas migration or well integrity issues.

To address this, the operator selected a Whisper™ variant of the IS‑MAX — an intrinsically safe flowmeter specifically engineered for ultra‑low differential pressure applications. With a pressure drop of only 0.07 PSID, the IS‑MAX enabled precise flow measurement without disturbing the natural venting dynamics of the well.

Data from the meter was routed through an intrinsically safe barrier to an on‑site telemetry shed, allowing seamless integration with the central SCADA system. This setup enabled remote monitoring without altering the existing vent line design or adding risk to field operations. The IS‑MAX’s robust performance, paired with its suitability for classified environments, delivered reliable, real‑time insight while maintaining compliance with safety and operational standards.

Industry impact

Effective SCP and SCVF monitoring are critical to long‑term management of well integrity. Whether during P&A operations or ongoing surveillance of marginal wells, accurate flow and pressure data allows operators to identify sustained venting activity, verify the success of cementing operations, and prioritize high‑risk wells for intervention. Additionally, measured SCVF rates can be used to estimate gas fluxes escaping the wellbore into surrounding formations or the atmosphere, supporting risk assessments for groundwater contamination or natural gas emissions. As environmental regulations expand and emissions accountability becomes more granular, high‑resolution diagnostics like those provided by IS‑MAX are essential for both compliance and operational efficiency.

By enabling engineers to detect leaks earlier, measure flow accurately without impacting system pressure, and streamline data acquisition across their well inventory, these instruments support safer abandonment practices, better natural gas flow control, and reduced remediation costs over time.