Acetylene Sample Analysis in a CID1 Hazardous Location

Even in small concentrations, acetylene is highly reactive and unstable. Its presence in ethylene production can disrupt downstream processes and increase the risk of reactions. To address this, some cracking facilities incorporate thermal‑catalytic hydrogenation systems to catalyze acetylene and increase ethylene yields. While effective, the selective removal of acetylene must be tightly controlled to avoid under‑ or over‑conversion, both of which can impact product quality and safety.

As such, monitoring the effectiveness of this removal while ensuring trace levels of acetylene remain within acceptable limits requires regular and precise gas sampling. While many facilities use online analyzers for continuous process control, post‑hydrogenation acetylene analysis is often conducted through closed‑loop lab‑based sampling. These laboratories provide actionable data that helps confirm both process efficiency and operational safety.

Case study: closed loop sample line

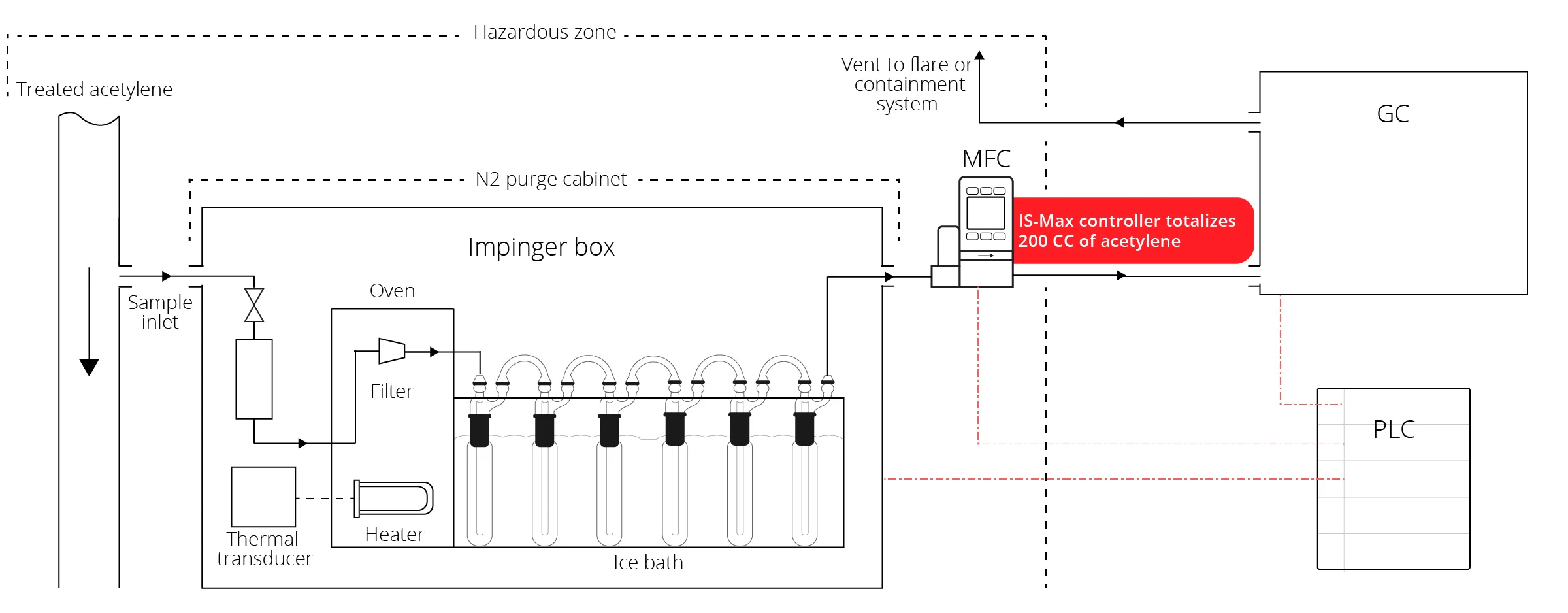

In a North American process laboratory operating within a Class 1, Division 1 (C1D1) hazardous area, a gas sampling system monitored post-hydrogenation acetylene conversion from a side‑stream off the main process line. A portion of the hydrogenated gas was diverted through a sample tap and conveyed via an electrically heated transfer line to prevent premature condensation before cooling. The sample then entered a thermally insulated icebox containing an impinger train, where it was deliberately chilled to condense and remove volatile components and particulates.

After preconditioning in the ice bath, the sample was routed through an Alicat® Scientific IS-Max™ mass flow controller and into a gas analyzer to verify that residual acetylene concentrations were reduced to safe operating levels. The IS‑MAX maintained a precise 0 – 200 CCM sampling flow rate at an inlet pressure of 15 PSIG, with setpoints controlled by a central PLC via Modbus RTU over RS‑485. Its ± 0.5% of reading or ± 0.1% of full‑scale accuracy ensured stable flow and prevented sample loss or pressure fluctuations that could compromise trace measurements.

Outcome

In off‑stream sampling systems where gas is not returned to the process line, steady, traceable flow is essential for reliably quantifying contaminants such as acetylene. The IS‑Max is the industry’s first fully integrated mass flow controller to achieve both C1D1 and Zone 0 certification. Unlike most intrinsically safe systems, which require separate flow/pressure sensors and external control hardware, Alicat’s design integrates sensing and actuation into a single instrument. This reduces system complexity, minimizes wiring, shortens installation time, and improves safety while maintaining high measurement accuracy and fast control response.

Other intrinsically safe instrumentation may provide basic flow indication, limited pressure control, or standalone data logging, but the IS‑MAX combines all of these functions with active compensation for pressure changes, precise closed‑loop flow control, and direct integration with plant digital control systems to deliver a complete solution for high‑precision, automated sampling.

The benefits extend beyond this single process. In the wider oil and gas industry, achieving high‑precision, intrinsically safe flow control in a compact, integrated package reduces the footprint and complexity of sampling systems, improves compliance with hazardous‑area requirements, and cuts downtime for maintenance or reconfiguration. For operators, that translates into lower total cost of ownership, higher uptime, and more consistent data quality across multiple facilities. Technologies like the IS‑Max support safer operations, strengthening both regulatory compliance and efficiency in safety‑critical environments worldwide.