Pilot Pressure: Alicat Devices Paired with Dome Loaded Pressure Regulators

What is pilot pressure?

Despite the name, “pilot pressure” isn’t about how a pilot feels while landing a plane…

Instead, it refers to the pneumatic control signal that defines a regulator’s setpoint. In pressure control systems that use dome-loaded pressure regulators, this pilot signal is generated by a separate pilot device and directly determines how the regulator opens and closes to maintain the desired process pressure.

In applications with extreme temperatures and pressures, severe chemistry, mixed fluid phases, or other challenging operating conditions, a dome-loaded pressure regulator (DLPR) is often the preferred solution. Unlike conventional spring-loaded regulators, dome-loaded designs use a flexible diaphragm and an externally applied control pressure to balance against the process pressure. This operating principle allows them to handle large pressure differentials while maintaining stable, repeatable control across a wide range of flows.

Some common conditions where DLPR valves shine include:

- Operating pressures above 1000 PSI, where spring-based regulators struggle with stability and hysteresis

- Extreme process temperatures, including environments that degrade elastomers or mechanical springs

- High flow rates with wide turndown requirements

- Corrosive or reactive materials, where isolating the control device from the process is critical

Because a dome-loaded regulator cannot generate its own setpoint, its performance is largely determined by the device supplying pilot pressure to the dome. In simple systems, this pilot pressure may be provided by a manual regulator or a fixed pressure source. For applications that require dynamically adjustable setpoints, tight pressure tolerances, or integration into automated control systems, electronic pilot pressure control is often required to fully realize the regulator’s precision, responsiveness, and repeatability.

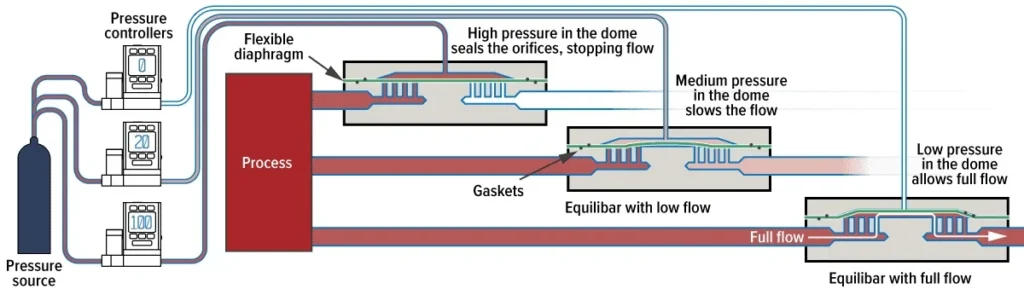

Raising the Equilibar

Equilibar back pressure regulators (BPRs) and flow control valves (FCVs) offer stable control across an extremely wide range of flow rates, with models offering control of valve flow coefficient (Cv) down to 1e-9. Equilibar valves also come in models with chemical resistance and high temperature tolerances up to 450ºC. The dome-loaded, multiple orifice design offers instantaneous control and exceptional precision for the most complex of applications. Using a flexible mechanical diaphragm as its only moving part to provide frictionless and stable operation, Equilibar valves provide superior precision and repeatability, especially for low flow rates, mixed phase fluids, corrosive media, and extreme temperatures and pressures.

Equilibar valves and Alicat precision instruments are complementary when used in combination. Both have extremely high resolution, allowing each to take advantage of the other’s high precision control.

Pairing an Equilibar back pressure regulator and Alicat pressure controller

In applications where the pilot or backpressure gas is non-toxic, such as air or inert gases, this approach also allows pilot pressure to be safely vented to atmosphere, simplifying system design.

Because the PCD incorporates both inlet and exhaust control valves, it can actively increase or bleed pilot pressure as needed to maintain the commanded setpoint. Working in tandem with pressure relief valves and other system-level pressure protection devices, this controlled venting improves system response, minimizes overshoot, and helps stabilize pressure during setpoint changes or transient conditions. By actively managing pilot pressure rather than relying on passive elements alone, the PCD enables smoother, more predictable control of dome-loaded regulators in demanding applications.

Pressure control in hazardous locations

Alicat’s intrinsically safe series of electronic pressure controllers are designed for use in classified environments where conventional enclosures or purge systems may be impractical. These controllers provide closed-loop electronic pilot pressure control while meeting applicable hazardous area requirements, enabling precise regulation without introducing ignition risks.

In one application, a North American gas company designing a pressure control system for pressurized vessels used an IS-Pro™ PCD to pilot a dome-loaded pressure regulator. By adjusting the pilot pressure proportionally, the ISPCD enabled high-resolution, closed-loop control of the DLPR, allowing vessel pressure to be regulated automatically in a Class I, Division 1 hazardous location. The system was configured to maintain vessel pressure between 0 and 100 PSIG (0 to ~6.9 bar), with inlet pressures ranging from 120 to 150 PSIG (8.3 to 10.3 bar). Pilot exhaust was vented to atmosphere, and the system operated across an ambient temperature range of 20 to 115 °F (−6.7 to 46.1 °C).

Closing thoughts

Key capabilities

- Compatible with a wide range of non-corrosive and corrosive fluids

- Available in absolute, gauge, or differential pressure

- ± 0.125% of full scale accuracy

- ± 0.08% of full scale repeatability

- 0.01 – 100% measurement and control range (10,000:1 turndown)