Inflating single-use bioreactor bags using dual-valve pressure controllers

The installation specifics vary by bioreactor manufacturer, but they always include an inflation step after the bag is placed into the container. At this point, the various gas lines and sensing ports are sealed shut, and the bag is inflated with an exhaust valve open to prevent over-pressurization.

Once the bag is fully inflated, the sensing, sampling, and other ports can be used. Following the final installation steps, the culture medium and cell strain are added and the bioprocess can proceed.

Challenges: Safety, automation, and process integrity

Bioreactor bags are not pressure vessels, and over-pressurization compromises their integrity – even if the bag does not burst, leak, or otherwise fail. The appropriate pressurization must therefore take into account the gases that will be introduced, consumed, and generated during the growth period, as well as the influences of culture medium, anti-foaming agents, and other fluids introduced into the broth.

It is also necessary for the vessel to be sufficiently inflated during installation. This ensures that the bag can support the full installation and setup process, including the introduction of various fluids.

The inflation process may be fully or partially automated, with controls built into the overall bioreactor controller system. In some facilities, inflation may be a completely manual affair, requiring an operator to start the process while making sure the system doesn’t over-pressurize. In either case, inflation may be completed using only a pressure controller. However, SUB manufacturers also recommend using a pressure controller and transducer for the best monitoring of the inflation process.

Various safeties work to ensure that the bioreactor bag is not damaged during setup, ranging from alarms built into controllers and transducers to interlocks that prevent inflation when the bag is improperly installed. The inflation process generally takes less than 30 minutes but is ultimately dependent on the volume of the vessel and the fill rate of the gas.

Solution: Dual-valve pressure controllers to inflate single-use bioreactor bags

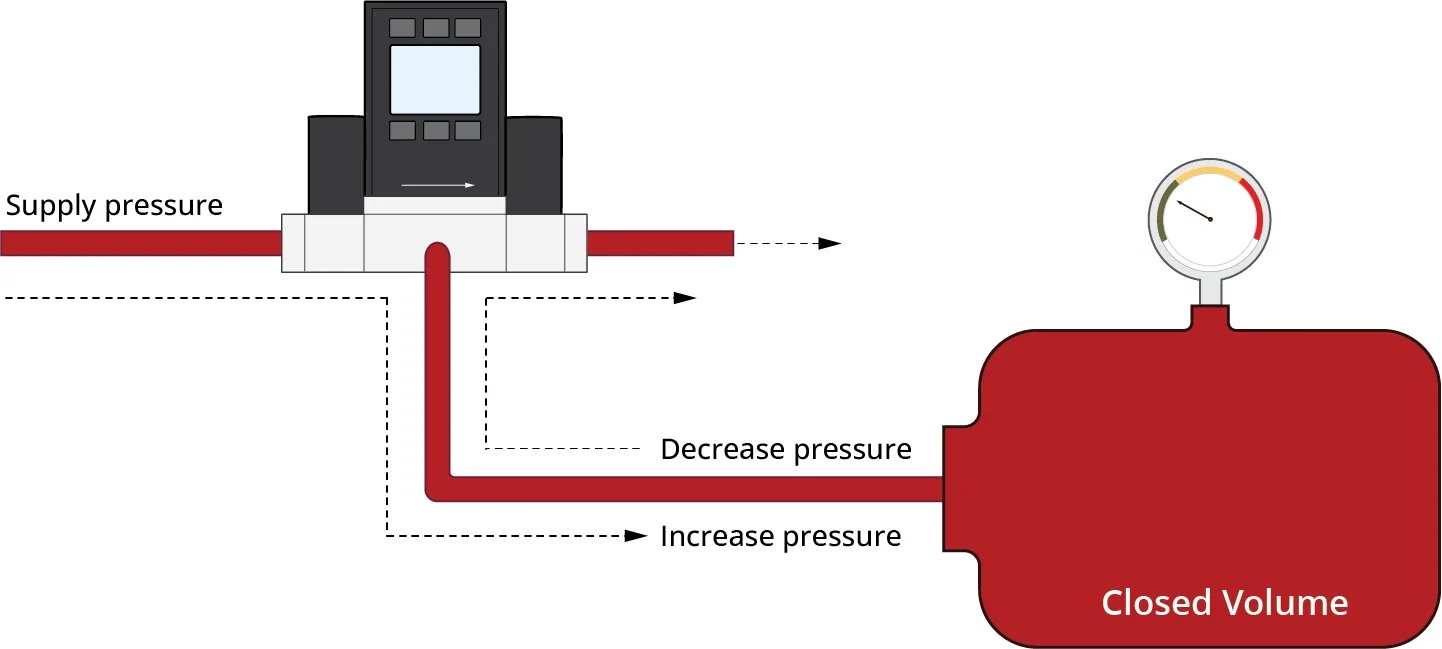

When inflating a SUB vessel, the closed volume shown here represents the bioreactor bag. The PCD initially inflates the bag to the chosen pressure setpoint, then actively relieves the excess air pressure as the bag is filled with liquid at a constant volumetric flow rate.

SUBs range in scale from milliliters to about 5,000 L – with several bag sizes at each order of magnitude. For example, a manufacturer may make bags at 50, 100, 250, 1,000, and 2,000 L, all of which will need to be inflated as part of the installation.

These bags come with instructions to fill them with air to a specific pressure setpoint. Additional pressure may be introduced (often about 1 PSIG) to remove any creases or folds in the bag based upon visual inspection. A dual-valve pressure controller ensures the air in the bioreactor does not exceed the manufacturer’s designed fill pressure, maintaining the integrity of the vessel at all times.

Following inflation, the bag is filled with liquid for the bioreaction to proceed. At this point, the air pressure in the bag can be exhausted at a rate matching the incoming liquid flow. As the pressure controller was designed with valves to accommodate specific inlet and outlet airflow rates, one Alicat dual-valve pressure controller can be used to manage single-use bioreactor bag pressures at all phases of the reaction process.