Choosing the Right Mass Flow Meter Technology

Accurate measurement and control of fluid flow are critical across diverse industrial applications and research fields. At Alicat Scientific, we offer mass flow devices built on three key technologies: Laminar Differential Pressure, Coriolis, and Thermal (MEMS). Each technology provides distinct advantages tailored to specific application requirements.

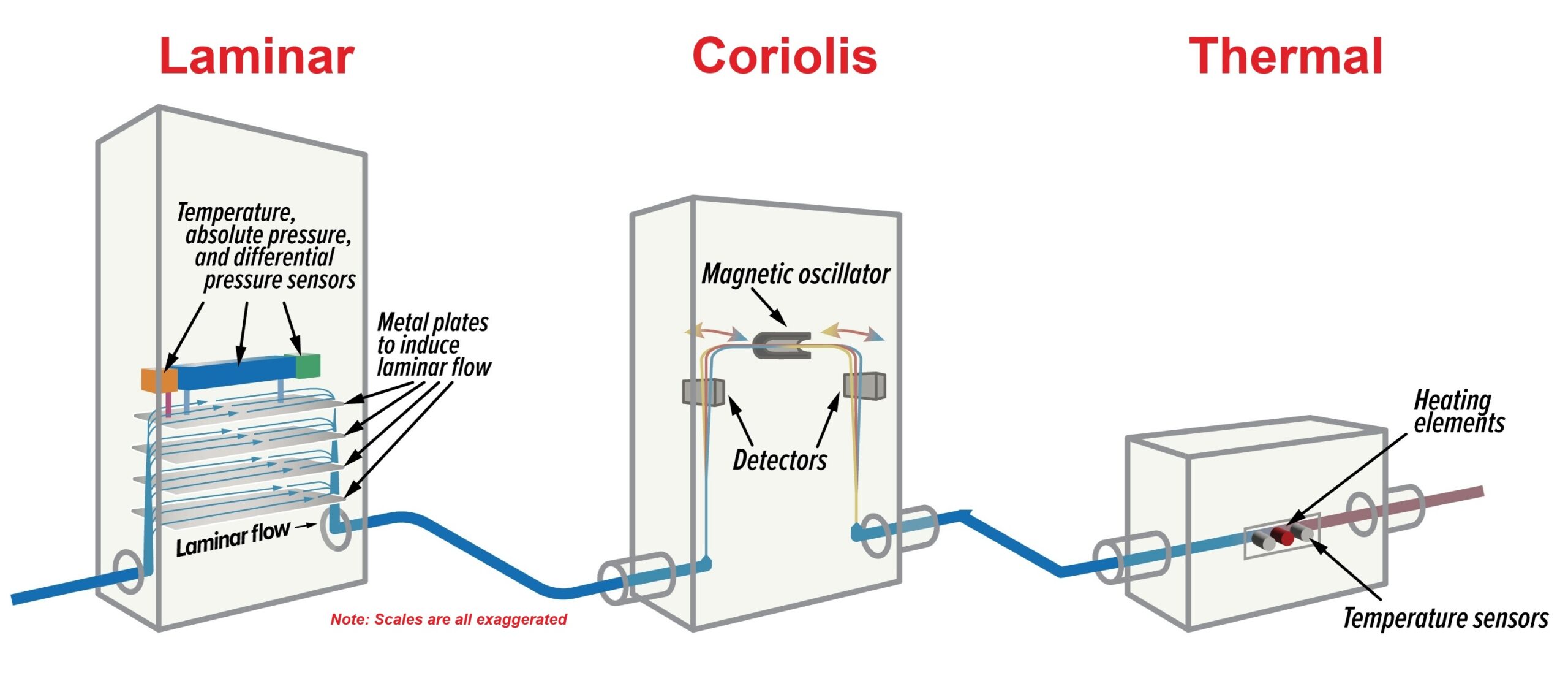

Figure 1. Diagram of Mass Flow Meter Technologies

Understanding Flow Meters and Controllers.

A flow meter measures the flow rate of a fluid traveling through a system, providing essential data for process control, safety, and efficiency. A flow controller, however, not only measures the flow rate but also regulates it to maintain a desired setpoint, ensuring consistent and accurate fluid delivery.

Selecting the appropriate type of flow meter is crucial for achieving accuracy, reliability, and efficiency in various applications. Understanding the distinct characteristics and advantages of each technology enables informed decision-making, ensuring optimal performance for your specific needs.

Laminar Differential Pressure

Laminar Differential Pressure (DP) technology measures true mass flow by applying the Poiseuille principle across a laminar flow element and incorporating temperature, absolute pressure, and differential pressure sensors. In this setup, fluid is forced into laminar (non-turbulent) flow, making the pressure drop directly proportional to volumetric flow. Because the instrument simultaneously measures temperature and absolute pressure, it can calculate actual mass flow rather than just volumetric readings. This approach yields highly precise and repeatable measurements, as the controlled laminar flow path and multi-sensor feedback maintain accuracy even under changing conditions.

How It Works

- Flow Conversion – The device contains an arrangement of thin metal plates that convert incoming turbulent flow into laminar flow.

- Pressure and Temperature Measurement – Sensors measure differential pressure, absolute pressure, and temperature within the laminar flow regime as the fluid passes across the plates.

- Flow Calculation – The pressure and temperature measurements are used in conjunction with the Poiseuille equation to calculate the flow rate.

Read more about the Laminar DP Operating Principle →

Key Benefits of Our Laminar DP Devices

- Multi-Variate Measurement – Simultaneously measures mass flow, volumetric flow, pressure, and temperature, with pressure control capabilities.

- Versatile Gas Compatibility – Gas Select and COMPOSER allow for up to 130 gases to be selected, or up to five constituents to be blended together for a custom gas blend without losing accuracy.

- Stable in Changing Environments – Extensive compensations for pressure and temperature effects enable highly accurate measurements even with changing conditions.

- Optimized Control – Onboard PID adjustment and Autotune for precise control stability.

- Ultra-Fast Response Time – Achieves control response times as low as 30 milliseconds, enabling swift adjustments and precise flow regulation.

- High Resolution – Provides measurable and controllable ranges from 0.01% to 100% of full scale.

- Ultra-Low Pressure Drop – Minimize pressure drop (as low as 0.07 PSID), delivering accurate flow control for systems with limited source pressure.

- Superior Accuracy – Achieves up to 0.5% of reading accuracy.

Coriolis

Coriolis technology measures true mass flow by detecting phase shifts caused by fluid movement through oscillating tubes. This direct measurement method is highly accurate and independent of fluid composition, making it well-suited for dynamic applications where fluid properties may change.

How It Works

- Tube Oscillation – The device contains one tube that is electromagnetically oscillated at its resonant frequency.

- Phase Shift Detection – When there is no flow, the tubes oscillate symmetrically. As fluid flows through, the tubes twist, creating a phase shift between sensors at different points along the tube.

- Direct Mass Flow Measurement – The magnitude of this phase shift is directly proportional to the mass flow rate, allowing for precise measurement.

- Density Measurement – In addition to mass flow, the resonant frequency of the tubes can be used to deduce fluid density.

Read more about the Coriolis Operating Principle →

Key Benefits of Our Coriolis Devices

- Fluid Independent – Measures mass flow accurately, even when fluid composition is changing or unknown.

- Material Compatibility – Suitable for both corrosive and non-corrosive gases.

- Multi-Parameter Measurement – Simultaneously measures mass flow, fluid density, and temperature.

- Integrated Totalizer – Devices can measure and accumulate the total amount of flow that has passed through the device, with easy reset functionality to start new measurements.

- Multiple Pressure Options:

- Economical Standard Option: Compatible with pressures up to 1,500 PSIA (103 barA) and has a reading accuracy of 0.6% for liquid and 1% for gas, even at low flow rates.

- High Accuracy Option: Handles pressures up to 4,000 PSIA (275 barA) and has a reading accuracy of 0.2% for liquid and 0.5% for gas, even at low flow rates.

Thermal (MEMs)

Thermal (MEMs) technology measures mass flow by monitoring temperature changes as fluid moves past heated elements. This approach provides a compact, cost-effective solution for low-flow applications and gases with stable compositions.

How It Works

- MEMs Sensor – small sensors which can measure one of a variety of physical states, including temperature.

- Temperature Differential – As the fluid flows, the downstream sensor registers a higher temperature, creating a temperature differential.

- Flow Rate Correlation – The temperature differential is directly proportional to the mass flow rate, as higher flow rates result in greater heat displacement.

Read more about the Thermal Operating Principle →

Key Benefits of Our MEMs Devices

- Wide Flow Range – Operates from 100 SCCM to 100 SLPM, with a turndown of 1,000:1.

- Multi-Gas Compatibility – Calibrated for nine gases, including Air, N2, O2, CH4, He, H2, Ar, CO2, and N2O.

- Compact and Lightweight – Features a hard-anodized aluminum flow body for durability in a lightweight design.

- Enhanced Features – Includes a totalizer for precise dosing, automated control, and easy customization.

When to use which technology?

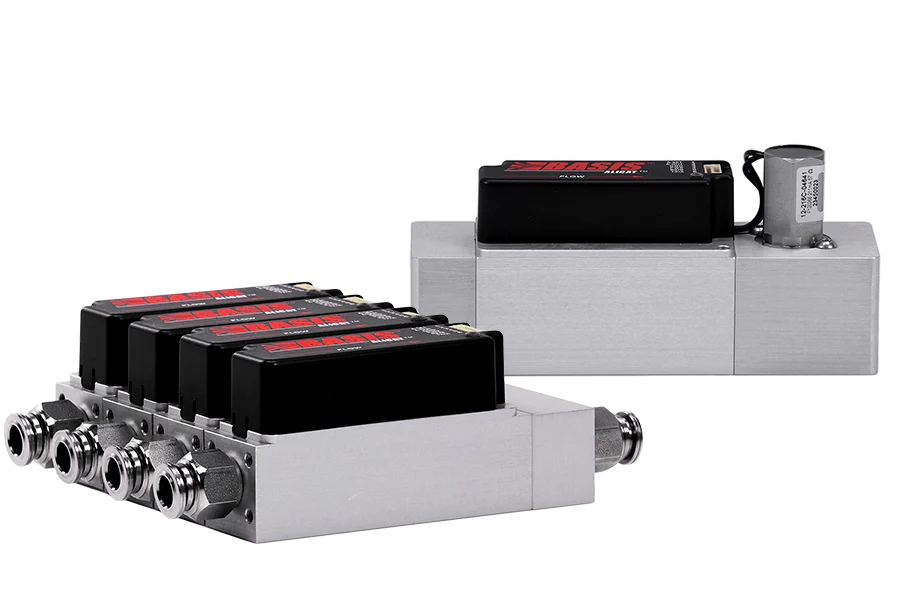

Compare the key specifications of Laminar Differential Pressure, Coriolis (CODA), and Thermal MEMs (Basis) flow technologies. This table highlights factors like gas composition requirements, operating temperature, pressure limits, control range, and ideal applications to help you choose the best fit for your needs.

High Pressure: 320 PSIA (22 barA)

- Fast response time

- Known gas composition

- Clean gases

- Gas mixing

High viscosity gases

- Sanitary applications and with corrosive, dirty, or aggressive gases

- Long-Term reliability

Applications with vibrational noise

- Insertion into pipes

- Lightweight and inexpensive

- Minimal drift over time

Aggressive gases

Find the Optimal Mass Flow Solution for Your Application

Selecting the right type of flow meter and measurement technology depends on your operational needs. Whether you require high accuracy, multi-gas compatibility, or fluid independence, Alicat has the right solution for you.