Flow control in direct air capture

Environmental concerns about global warming have led to the development of emerging technologies to mitigate new emissions of greenhouse gases. Although reducing these new emissions helps to reduce the magnitude of global warming, it does not reduce the impact of previous emissions which are already in Earth’s atmosphere.

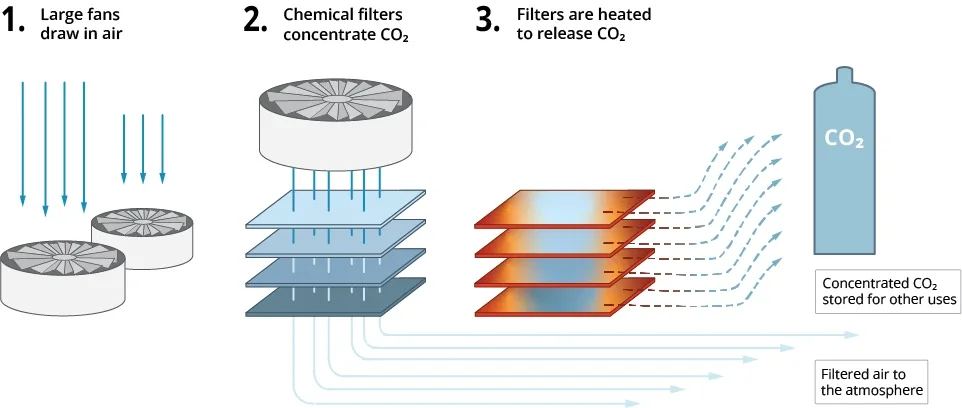

A practical solution to lower previous carbon dioxide and other greenhouse emissions is direct air capture, or DAC, which is the process of sequestering, storing, or reusing the CO2 or other greenhouse gases concentrated from ambient air.

Improving DAC systems

Many companies around the world are working to build more efficient DAC systems by researching, developing, and scaling improved methods of capturing CO2 from ambient air and reducing energy use while improving CO2 conversion rates.

Companies such as Verdox and Carbon Collect are testing novel methods to optimize DAC systems using technologies such as electro-swing adsorption and passive direct air capture (PDAC). Over time, these innovations along with other developments in the industry will lead to lower direct air capture costs, increasing the economic value of these systems. Verdox, a company using electro-swing adsorption in its DAC systems, developed a process which relies on electricity instead of heat to reduce the energy needed to capture and release CO2 from ambient or process gases. Alternatively, Carbon Collect has developed a method which passively captures ambient air without the use of fans, reducing the total energy of their DAC systems.

Alicat devices can optimize the research and development of DAC system design by providing flow and pressure regulation, including useful features such as:

- Totalizing and batching control options to record how much CO2, air, or process gas is being flowed or captured

- Gas compatibility with 98+ gases, including ambient air and CO2, for creating up to 20 custom-defined gas mixes in research settings

- Accurate, repeatable, precise, and fast measurement and control

- Various control and automation settings with analog, serial, and industrial protocol communication options

Using Alicat devices in DAC systems

Flow regulation

In most DAC systems, ambient air (or sometimes process gases such as flue gases) is collected using fans or pumps and stored in sorbents, or adsorption surfaces, until saturated to holding capacity. Then, incoming ambient air flow is stopped and vacuumed out. Lastly, captured CO2 is flowed to be sequestered, stored, or chemically processed.

Additionally, sometimes intermittent steps also occur to concentrate and purify the CO2 to regulatory standards needed for different industrial processes. Highly concentrated >95% CO2 gas mixes can be developed using this method.

Alicat mass flow controllers such as the MC-Series can be used to create input gas mixes for research and development DAC systems as well as to track and control CO2 gas moving through a DAC system, allowing for precise measurement of how much CO2 is being captured from the ambient air as well as flow control for storage or further chemical processing.

If using flue or other process gases instead of ambient air, Alicat mass flow controllers can additionally track the movement of these input gases.

Alicat’s MC-Series offers the following features and specifications for optimizing DAC system development:

- CO2 flow control up to 5000 SLPM with accuracy up to ±0.4% of reading and ±0.2% of full scale

- Warm up time <1 s

- Humidity range up to 95%

- Control response time <30 ms

- Repeatability up to ±0.2% of reading + 0.02% of full scale

- Custom gas settings for 98+ gases, allowing for research and development of different gas mixes with different sorbents

- Automation and communication options for continuous batching and system control

Pressure regulation

Alicat pressure controllers such as the PC-Series can be used to help create automated control of vacuum conditions in combination with vacuum pumps in DAC systems, ensuring that CO2 gas purity is not contaminated by unwanted ambient gases.

Alicat’s PC-Series include the following features to create ideal vacuum conditions in DAC systems:

- Absolute pressure control from 0–3000 PSIA

- Control range of 0.01% – 100% of full scale

- Control response time <30 ms

- Warm up times <1 s

- Various communication options for automated system control and batching