Flow and Pressure Control for Gas Chromatography

How to control flow and pressure of gases to achieve better process insights and decrease process variability

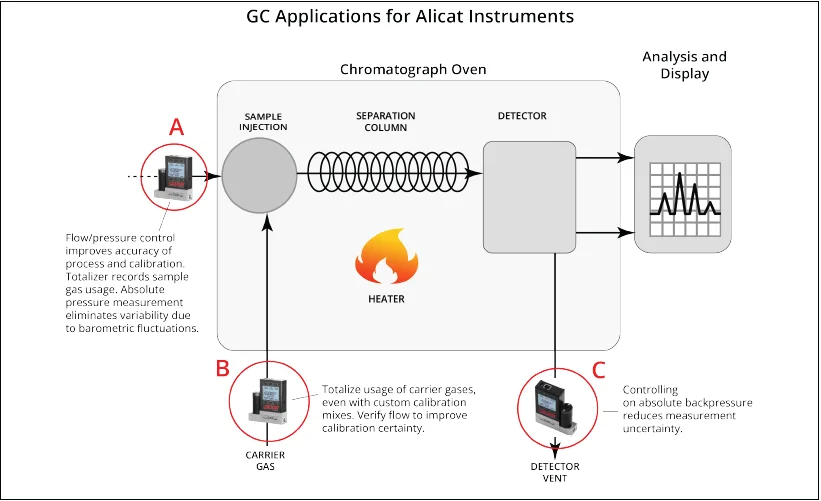

Flow and Pressure Control in a GC

Upstream Flow Control

An Alicat MC mass flow controller upstream of the GC (Figure 2 A) can regulate the process gas or batch a specific amount of gas volume on the sample line. Automatic batch dispensing can improve repeatability and simplify the analysis process.

The controller’s totalizer function can continuously log gas usage over time, both for record keeping and as valuable diagnostic data to interpret anomalies or unexpected results.

In an explosive environment, an intrinsically safe IS‑Max controller can maintain consistent flow control. Using a single device for metering and control simplifies the GC system design and improves safety by eliminating additional sensors, wiring, and valves.

Carrier Gas

The totalizer function on Alicat instruments records carrier gas usage, even for custom calibration mixes. The totalizer function can also retain flow history, which can be useful both for record keeping and for diagnosing process anomalies.

Downstream Flow Control

Absolute and Gauge Pressure Control

The ability to switch between gauge pressure and absolute pressure makes Alicat instruments much more flexible than other metering and control options.

Humidity

Gas chromatography results can be affected by any changes in operating conditions, etc. Alicat instruments can control mass flow or volumetric flow while also monitoring temperature, absolute pressure, gauge pressure, humidity, and other variables. The instruments can be configured using the built‑in display or using a variety of industrial communication protocols. By providing accurate data and combining metering and control, Alicat instruments simplify GC setups while improving their accuracy, calibration, and safety.

Summary

- Improve measurement accuracy

- Remove variability due to barometric fluctuations

- Reduce calibration uncertainty

- Simultaneous humidity monitoring

- Monitoring/control throughout the GC for design simplicity

- Intrinsically safe options for use in explosive environments

IS Intrinsically Safe Instruments

Small Electronic Pressure Controllers and Meters

MB Series Mass Flow Meter