Annual Recalibration FAQ

Recalibrating your Alicat meters and controllers ensures they are performing in tip-top shape. In this article, we answer common recalibration questions.

When do I need to get my Alicat device calibrated?

All Alicat meters and controllers should be recalibrated annually to maintain the limited lifetime warranty of the device.

You can find the date of the device’s most recent calibration on the back of the device, or stored in MENU > ABOUT > DEVICE INFO.

Why do I need to recalibrate my device?

Over time, particulate deposits or minor physical changes within the flow body or internal electronics can lead to deviations from the calibrated flow curve. Recalibration brings instruments back to their optimal calibration specifications.

What is included in the annual recalibration?

Each recalibrated device is returned to the customer with a NIST-traceable certificate of calibration that includes parameters and conditions related to the calibration.

What happens if damage requiring more than calibration is found?

Service technicians will evaluate the damage and determine repair needs on a case by case basis.

Will my device be updated or reconfigured during recalibration?

How long does it take to recalibrate a device?

It typically takes 15 business days after arriving at the factory or service center, however lead time may vary.

Where can Alicat instruments be calibrated?

We recommend that all devices are returned to an Alicat-approved facility for recalibration. Many devices are recalibrated in our US office, however we also have service centers in China, India, and the Netherlands.

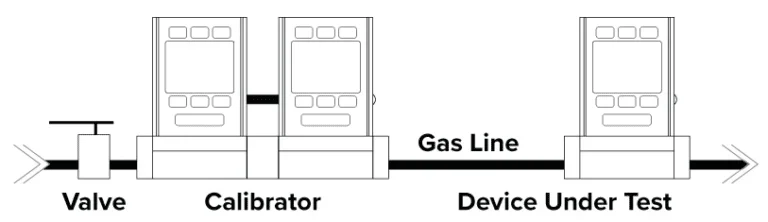

How is my device calibrated?

Alicat calibrations evaluate readings at five points within the full scale range of your device: 0%, 25%, 50%, 75%, and 100% of full scale. You can also request a custom calibration, for which you choose the specific calibration points and may use more than 5. These readings are compared with readings taken from one of our in-house flow or pressure standards.

When calibrating controllers, additional valve calibration is required. Service technicians often alter the PID tuning of a device to improve control performance.

How do I request a recalibration from Alicat?

Fill out a service request form. Once we receive your request, we will issue you an RMA (Return of Materials Authorization) and send you shipping instructions.

FastTrack Ordering

METER RANGES

2 SCCM – 500SLPM

CONTROLLER RANGES

2 SCCM – 100SLPM

Service and Support

Whether it is time for your instrument’s annual recalibration or your instrument needs a repair or upgrade,

you can fill out the Service Request Form below, email us, call us, or start a live chat session to get the service process started.