- Flow Controllers & Meters

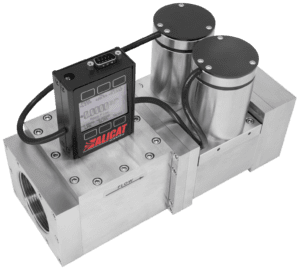

- MC–Series: Gas Mass Flow Controllers

model

MC–Series: Gas Mass Flow Controllers

- Full-scale flow rates between 0.5 SCCM and 5000 SLPM for all gases (10,000 SLPM for H2)

- Monitor four variables: mass flow, volumetric flow, pressure, and temperature

- Control one of three variables: mass flow, volumetric flow, or pressure

- 98+ gas calibrations preloaded and user-selectable

- Local, analog, or digital control, including industrial protocols

Beloved by metrology departments, cherished by researchers, and depended on by systems engineers – the MC-Series does more, and does it faster.

Specifications

Performance (most ranges)

- Steady state control range: 0.01% – 100% of full scale

- NIST-traceable calibration

- Standard accuracy: ±0.6% of reading or ±0.1% of full scale, whichever is greater

- High accuracy: ±0.5% of reading or ±0.1% of full scale, whichever is greater

- Repeatability: ±(0.1% of reading + 0.02% of full scale)

- Typical control response time: as fast as 30 ms

- Warm-up time: <1 s

Specification sheets (by full-scale flow rate):

0.5 – 5 SCCM 10 SCCM – 20 SLPM 50 – 10,000 SLPM

Operating conditions

- Compatible gases: 98+ pure and mixed non-corrosive gases

- Operating temperature: –10°C to +60°C

- Full scale operating pressure: 160 PSIA (11 barA)

All MC-Series Specifications (by full-scale ranges)

Customization Options

Do you have unique requirements? That’s our specialty.

Build and performance options

- Communication protocol: Analog (4-20 mA, 0-10 Vdc, 0-5 Vdc, or 1-5 Vdc), RS–232, RS–485, DeviceNet, EtherCAT, EtherNet/IP, Modbus RTU or TCP/IP, PROFIBUS, PROFINET

- Display: Backlit monochrome or TFT color; integrated or panel–mount

- Process connections: NPT, SAE, AN, BSPP/G, compression, VCR, or VCO fittings

- Elastomers: Viton, FFKM, EPDM, Silicone

- Calibration: Standard, high-accuracy; custom calibration points

- Ingress Protection: IP40, IP66, IP67

- Hazardous Environment Rating: CSA Class 1 Div 2, ATEX Class 1 Zone 2

Included with all MC-Series

- Setpoint ramping and limits: Control your process as fast or slow as desired with ramp rates. Protect your process from inadvertent setpoint changes with setpoint limits.

- Valve close and valve open override: Quickly stop all flow or vent your system as needed with alarms.

- Totalizers and batch control: Track total flow every 1 ms or dispense precise volumes with our integrated totalizers.

Valve options

Accessories

Included with purchase

- FlowVision software

Sold separately

- Process port fittings and filters

- Power supplies

- Communications cables and conversion cables

- BB3 and BB9 multi-drop breakout boxes

Need Devices Now?

Online Ordering*

*Available in CA, US, MX. If your country is not displayed, or you’re looking for faster shipping, contact us for more options: +1-520-290-6060 or via email at info@alicat.com.

Explore More at Alicat

- MCQ-Series | High operating pressures (320 PSIA)

- MCW-Series | Low pressure drops (0.07 PSID)

- MCS-Series | Corrosive gases (128+ gases, including 32 corrosives)

- CODA Coriolis | Fluids of unknown or changing composition; Pressures up to 4000 PSIA

Not sure which mass flow controller is the best for you?