Search this article

Cambridge CMOS Sensors characterizes and calibrates gas sensors using mass flow control

Cambridge CMOS Sensors (purchased by ams in 2016), is an industry leader in sensor technology. Their patented CMOS MEMS gas sensors use micro-hotplate technology to provide lower power consumption and faster response times for monitoring air quality and hazardous gases.

Challenge: Testing CMOS sensors requires fast flow control flow for a wide range of testing conditions

Cambridge CMOS Sensors needed a test platform for characterization and calibration of the sensors, during which carbon monoxide, ethanol, or volatile organic compounds (VOCs) would be pumped into a test chamber with each sensor.

Because their own sensors are so fast, Cambridge CMOS Sensors needed a mass flow control system that also responded rapidly to generate varying gas concentrations in the test chamber. Each test would require different concentrations of the gases at flow rates ranging from 0.1 ml/min to 500 ml/min. Fast flow stabilization was also necessary to gather transient data and to conduct leak testing of the test chamber.

Solution: Fast, flexible mass flow control system with 2 standard controllers, 2 anticorrosive controllers, and 1 anticorrosive meter

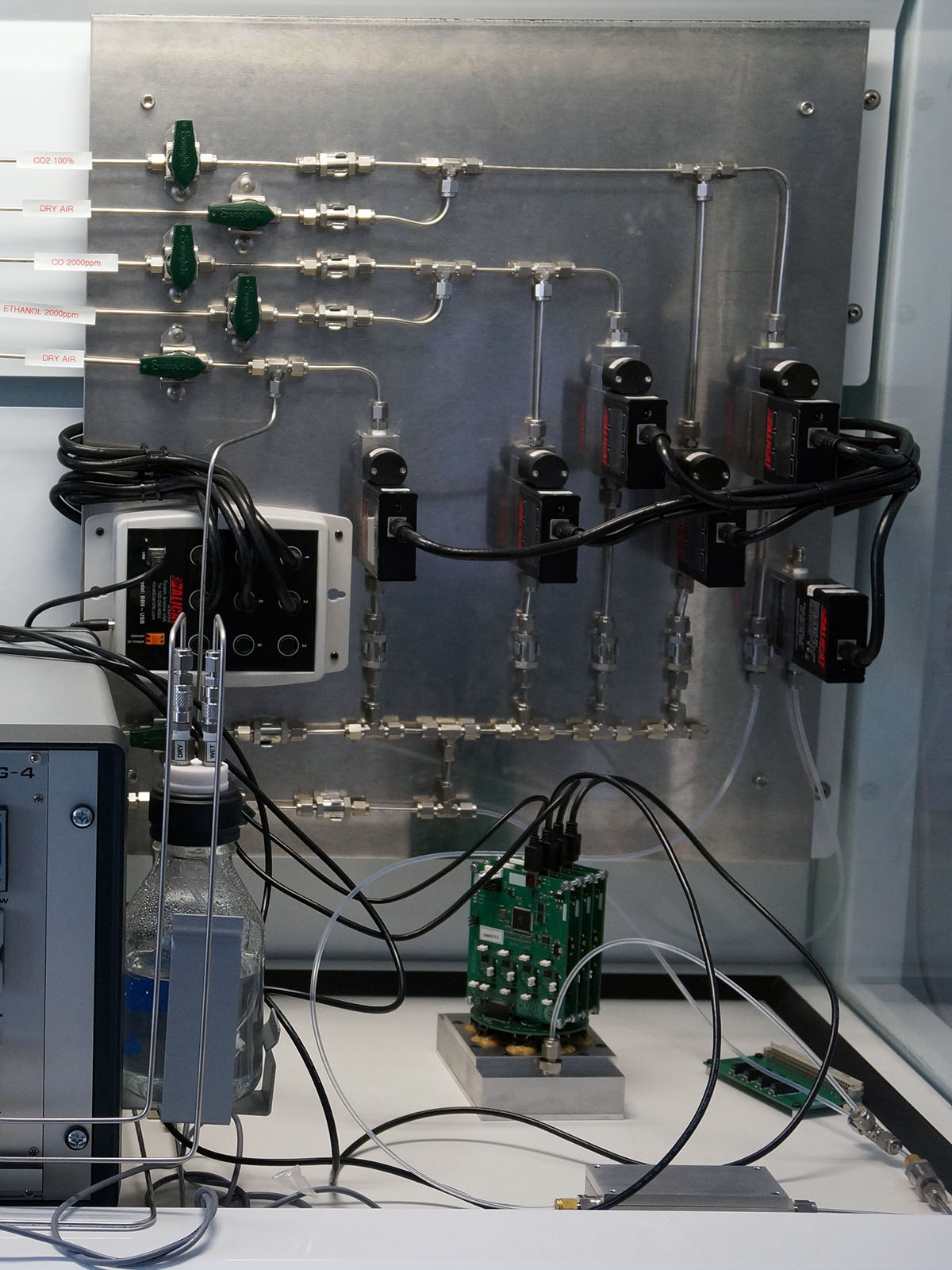

Mass flow control system in situ at Cambridge CMOS Sensors

Mass flow control system, showing (front to back) the BB9 distribution box, 3 standard mass flow controllers, 2 anticorrosive controllers and 1 anticorrosive mass flow meter

Premier Control Technologies responded to these requirements with a responsive and flexible Alicat mass flow control system. The 50-ms valve response times for setpoint changes ensure that test gas concentrations are achieved rapidly and remain stable for the duration of each test. Alicat’s on-board multiple gas calibrations and wide controllable range significantly reduced the equipment costs for setting up the sensor test platform. Each 0.1-500 ml/min flow range could be covered by just two mass flow controllers (500-ml/min and 10-ml/min models), with local pipework tees allowing high or low flows to be selected.

Two pairs of mass flow controllers were selected: one pair of standard controllers for carbon monoxide and ethanol, and a second pair of anticorrosive controllers for the volatile organic compounds. These four controllers were paired with a fifth controller for dilution into clean air, and an anticorrosive mass flow meter to monitor leak rates from the test chamber. All six instruments feature Alicat’s Gas Select COMPOSER, which provides gas properties data for 98+ gases and gas mixtures. This makes the devices “future-proofed” and ready to accommodate additional testing with new gases.

Powering and communicating with the flow control system

These instruments receive power and communicate through Alicat’s BB9-USB distribution box, which can connect up to nine mass flow or pressure instruments to a computer via a single USB connection and power supply. The fact that Cambridge CMOS Sensors can operate the controllers locally using the touchpad interface means they were able to complete preliminary testing without having to program the units through a computer. Now that their automated test platform is in place, they can control all the units over multi-drop RS-232 using their proprietary software control system.

This article comes courtesy of Premier Control Technologies, Alicat’s distributor for the United Kingdom.