Search this article

LD Integrated Technologies characterizes medical device flows using LabVIEW pressure control

LD Integrated Technologies (LDIT) is a consulting firm that specializes in system integration and automated testing projects. The firm often develops custom hardware, circuit design, embedded firmware, and software to meet the needs of their customers. LDIT focuses especially on integration projects within the medical device, aerospace, manufacturing, automotive, and oil and gas industries.

LD Integrated Technologies (LDIT) is a consulting firm that specializes in system integration and automated testing projects. The firm often develops custom hardware, circuit design, embedded firmware, and software to meet the needs of their customers. LDIT focuses especially on integration projects within the medical device, aerospace, manufacturing, automotive, and oil and gas industries.

Challenge: Controlling pressure to characterize a medical device prototype

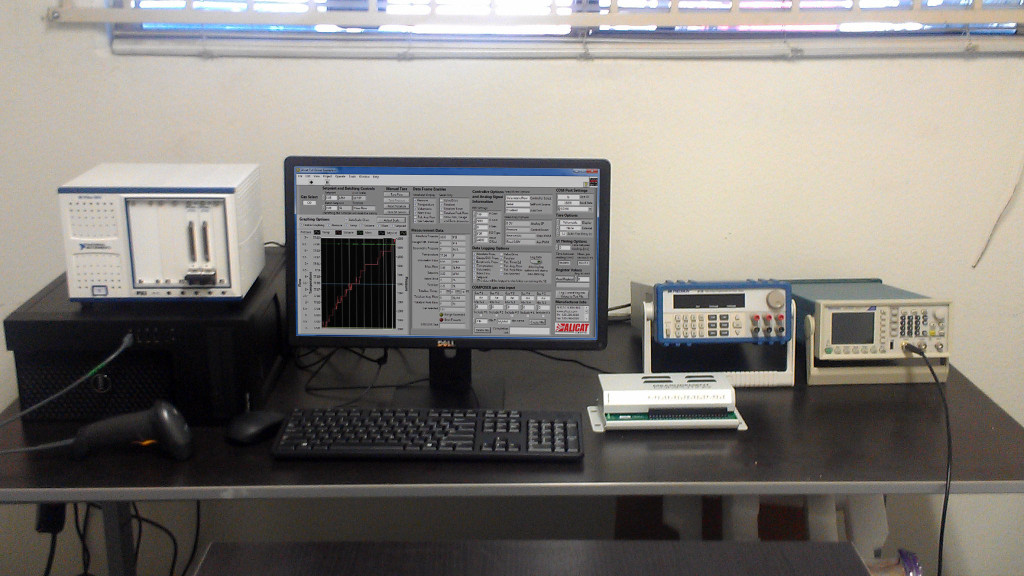

LDIT worked with a medical device company to develop a system to visually track a slow-moving object as a means to determine the flow rate for a diabetes-related application. The system ultimately needed a camera, a syringe pump, a pressure transducer, and the ability to communicate with LabVIEW.

Early in the development of this system, LDIT designed a high-fidelity prototype that would determine product feasibility. The prototype required the use of a pressure controller that could mimic the design pressure characteristics of the medical device and its operation in relation to the human body. The testing process was to incorporate flow characterization of the prototype throughout the full range of possible real-world pressures it might encounter. This would ensure that the device exhibited the desired flow rates at each of these test pressures.

Pressure control requirements

- Capable of maintaining a stable pressure at a precise point within a closed volume, while receiving positive pressure at its inlet and exhausting to a vacuum pump.

- Built of stainless steel materials to flow fluids without corrosion.

- Compatible with LabVIEW, as the medical device company already used this control software.

Solution: Alicat dual-valve pressure controller with remote sense port

LDIT came to Alicat Scientific for their pressure control solution. They first came across our LabVIEW drivers, which are used for easy remote monitoring of flow data and control of instrument setpoints and other functions.

The instrument itself was a dual-valve pressure controller with a remote sense port. Built with an absolute pressure sensor and two valves, this device is able to maintain precise control down to sub-atmospheric pressures within a closed volume. The remote pressure sense port can be plumbed anywhere in the system to maintain pressure at that point.

When technical issues come up during integration, LDIT needs answers right away so they can quickly ship the test setup to the customer. Our applications engineers are readily available to help with both instrument operation and LabVIEW drivers, which has helped LDIT ship systems on time.

Conclusion

The test system designed and built by LD Integrated Technologies made the medical device company’s R&D process more efficient. They were able to use the LabVIEW-controlled pressure controller to test a variety of pressure conditions, making it easy to mimic real-world situations and put the prototype medical device through its next phase.

Learn more: Catagen tests automotive catalysts using mass flow control