- Flow Controllers & Meters

- BASIS™ MEMS Thermal Mass Flow Meters & Controllers

model

Small flow mass flow instruments with the performance of a premier product.

BASIS™ MEMS Thermal Mass Flow Meters & Controllers

Small flow mass flow instruments with the performance of a premier product.

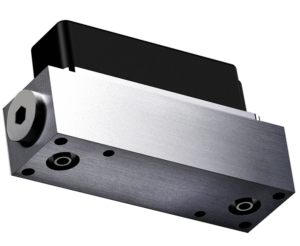

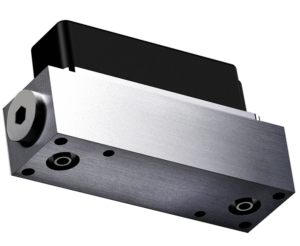

Alicat Scientific’s smallest mass flow controller uses MEMS thermal technology to measure mass flow. Cost-effective, small enough to fit in the palm of your hand and yet packed with impressive performance. Work with our engineering team for custom manifolds and gas mixing arrays.

- Accurate flow control in a compact, durable, metal flow body.

- Run sophisticated flow-control scripts using a fast, robust Alicat ASCII command set.

- Dispense dosing and batches with a built-in totalizer.

Compact manifolds

Ideal for benchtop bioreactors, glass manufacturing, and OEM builds with space constraints. Contact us with your specifications.

Easily connect to PC or PLC

Available with a wide range of fittings

Built to your process

Quick Specs

| Full-scale flow ranges | 100 SCCM to 100 SLPM |

| Fluids | Air, N2, O2, CH4, He, H2, Ar, CO2, N2O |

| Accuracy | As good as ±1.5% reading or ±0.2% full scale, gas dependent |

| Measurement & control ranges | 0.1% – 100% of full scale (1,000:1 turndown) |

| Flow repeatability (2σ) | ±0.25% of reading or ±0.05% of full scale |

| Sensor response time | < 6 ms |

| Control response time | As fast as 100 ms |

| Operating temperature | 0 – 50°C |

| Operating pressure | 0 – 145 PSIG |

| Humidity | 0 – 95% non-condensing |

Build Options

| Communication protocols | Alicat ASCII and Modbus-RTU over RS–232 or RS–485 |

| Analog Communication | 4-20 mA or 0-5 Vdc |

| Process connections | NPT or SAE |

| Ingress Protection | IP40 |

| Dimensions | As small as 0.88″ (22.23 mm) x 2.7″ (68.6 mm) x 1.55″ (39.4 mm) (WxDxH) |

Above specifications apply to most ranges.

Downloads

Purchase Now*

BASIS meters and controllers are available in our online shop.

Buy select devices online

*Available in CA, US, MX. If your country is not displayed, or you’re looking for faster shipping, contact us for more options: +1-520-290-6060 or via email at info@alicat.com.

Need downports or machined fittings?

Our fast prototyping will help you get to a production build quickly.

BASIS improves industry efficiency

Verify flow and optimize carrier gas control in gas chromatography

Enable full system stability. Fluctuations in flow rate disrupt the detection of chemical compounds. Tightly regulate carrier gas flow rate to ensure accurate compound detection, using a BASIS electronic mass flow controller.

Lowering cost and increasing speed of biologics production

Ensure your process is repeatable and scalable. BASIS provide accurate and responsive gas flow with a large turndown ratio and integrated gas selection. The number of spares required is reduced without sacrificing performance.

Ensure consistent batches in glass production

BASIS mass flow devices are used in burner control applications to control gases that heat the glass and facilitate drawing. Scripting and electronic control make your process repeatable and precise. Great for production of lab-quality and other high-volume, low-variability glass.

Gas mixing in molar ratios

Use BASIS mass flow controller’s intuitive serial commands to make gas mixtures in molecular proportions, and stop paying premiums for custom mixes.