Search this article

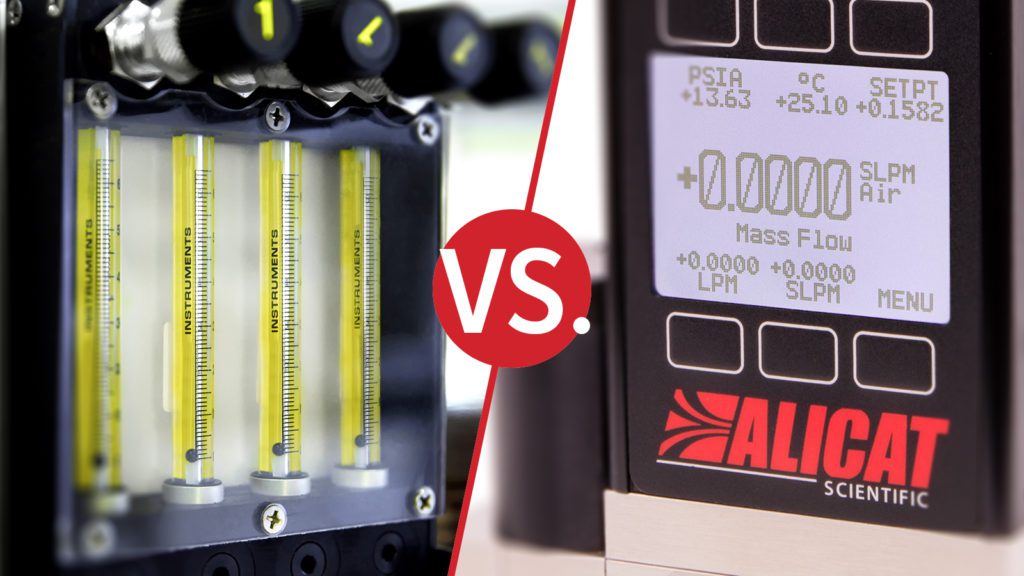

Calibrating a variable area flow meter with an Alicat

Variable area flow meters, commonly known as rotameters, use the pressure of a flow stream to determine a volumetric flow measurement. The pressure causes a ball within a conical tube to float, and the height is directly correlated with the flow rate of the gas or liquid. When operating in standard fluid, temperature, and pressure conditions, the volumetric flow equals the mass flow of the fluid.

Each variable flow meter is calibrated to a specific gas, standard temperature, and standard pressure. Rotameters provide high accuracy measurements when operating within these specific calibration conditions, however this accuracy decreases as process conditions change. It is important to calibrate a rotameter using its original calibration conditions. If a calibration lab is not easily accessible, an Alicat mass flow controller can be used to perform calibrations.

Challenge: Fluctuating temperature and pressure conditions

It is important to regulate temperature and pressure conditions during calibration to ensure the rotameter is properly calibrated. Most industrial environments are kept within a few degrees of one another, so temperature-induced inaccuracies tend to be a minimal. If needed, a thermostat can be adjusted to match the calibration conditions more closely.

Pressure conditions tend to be a bit more variable, due to factors such as local barometric pressure differences or operation at varying altitudes. This can significantly impact the accuracy of the calibration. The local pressure can easily be measured and compared to the calibration conditions using standard sensors.

Solution: Maintaining pressure and measuring flow with a mass flow controller

Alicat mass flow controllers have two important features that make them ideal for calibrating variable area flow meters. The first is the closed loop pressure feature and he second is multivariate measurement of mass flow rate, volumetric flow rate, pressure, and temperature. This means that one mass flow controller can be used to maintain pressure while simultaneously providing mass flow rates.

To perform the calibration, follow these steps:

- Ensure that the outlet pressure of the variable area flow meter is known.

- Plumb a mass flow controller with a downstream valve configuration inline and downstream of the rotameter. Make sure the device is in closed loop pressure control mode.

- Ensure the gas selection and STP settings on the Alicat are identical to the calibration conditions of the variable area flow meter.

- Set the back pressure control point on the Alicat to equal the outlet pressure of the rotameter.

- Introduce a flow and use it to calibrate the variable area flow meter.

Here are a few tricks to maximize calibration accuracy:

- Adjust ambient temperature and pressure conditions so that the mass flow controller matches the standard conditions of the variable flow meter

- Put the Alicat as physically close as possible to the variable area flow meter

- If the ranges and gases allow, use a low pressure drop flow controller to minimize the pressure drop

This setup allows the Alicat to precisely control the rotameter’s pressure, ensuring the calibration is performed at the exact calibration conditions.