Search this article

Upgrading reactive sputtering systems with closed loop flow control

Reactive sputtering, a physical vapor deposition (PVD) technique, is used to coat surfaces in a variety of manufacturing processes. Common examples include:

- Flat-panel displays for televisions and cell phones

- Photovoltaic coatings on solar cells

- Optical coatings on sunglasses

- Decorative coatings on hardware and automotive components

- Insulating coatings on architectural glass

Here we discuss a few challenges encountered in reactive sputtering applications and suggest mass flow control solutions to upgrade your PVD system.

Challenges: Regulating reactive gas flow and preventing target poisoning

The partial pressure of the reactive gas significantly affects thin film characteristics. As this pressure is directly proportional to the gas flow rate, it is critical to carefully control the amount and distribution of the reactive gas in the vacuum chamber.

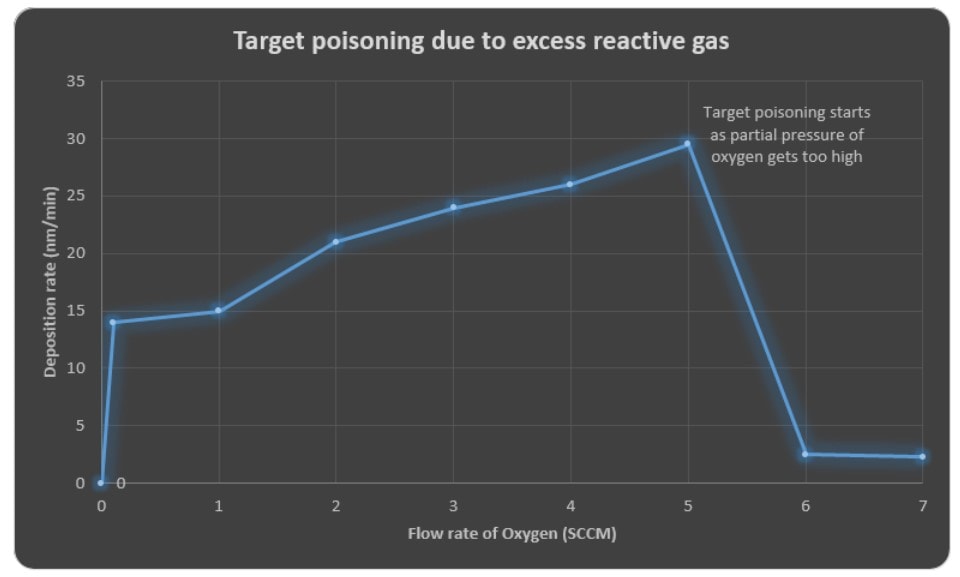

It is also important to maintain the condition of the target during the sputtering process. While increasing reactive gas flow to the process speeds up the chemical reaction, it can also lead to full coverage of the target or “target poisoning.” This may decrease the deposition rate and lead to changes in vacuum and voltage levels that damage the target and substrate.

Solution: Versatile, drop-in compatible devices with closed-loop control

An open-loop control method can be used to modulate reactive gas flows, deposition rates, and thin film properties with some degree of precision. However, much tighter closed-loop control is possible when residual gas analyzers (RGAs) are used in combination with mass flow controllers (MFCs). RGAs can be used to monitor the partial pressures of gases and to command flow controller setpoints, improving control over the “transition” state of the target and preventing target poisoning.

Advantages of Alicat mass flow control:

- Fast response times | Electrochemical reactions may occur only milliseconds after the target contacts the substrate. Alicat MFCs have an indication response time of 10 ms, and a typical control response time of 50-100 ms for vacuum applications. Controllers are additionally equipped with a field-adjustable PID algorithm, providing increased control performance.

- Compatibility with common reactive gases across a wide flow range | Each MFC can easily switch between 98+ preloaded gas calibrations including oxygen, nitrogen, acetylene, and methane with a 0.01% to 100% controllable range (10,000:1). This reduces the number of devices required in the sputtering setup.

- Easy integration into existing setups | Devices are compatible with mechanical and electrical connections used on existing sputtering setups. Many digital and analog interfaces are additionally available, including RS-232 and RS-485 in combination with DeviceNet, EtherNet/IP, or EtherCAT.

Alicat offers several device configurations, so you can choose the one that will best fit into your existing setup with minimal need for redesign:

- MCE-Series SEMI standard MFCs have 1/4″ VCR fittings that match end-to-end with SEMI standard MFCs

- MCV-Series MFCs also have 1/4″ VCR fittings and a pneumatic shutoff valve

- MC-Series standard MFCs are configurable with a variety of fitting options