Search this article

Regulating cold plasma flow and pressure

Plasma, the 4th state of matter, makes up a remarkable 99% of all mass in the universe, including stars and lightning. Cold plasma, sometimes called non-thermal plasma or non-equilibrium plasma, is a special type of plasma. While other molecular and atomic constituents remain near room temperature, cold plasma is made at ambient conditions when electron temperatures in gases are raised to more than 10,000 K. As a result, it is possible to touch cold plasma without burning oneself. Common examples of cold plasma include fluorescent and neon lights.

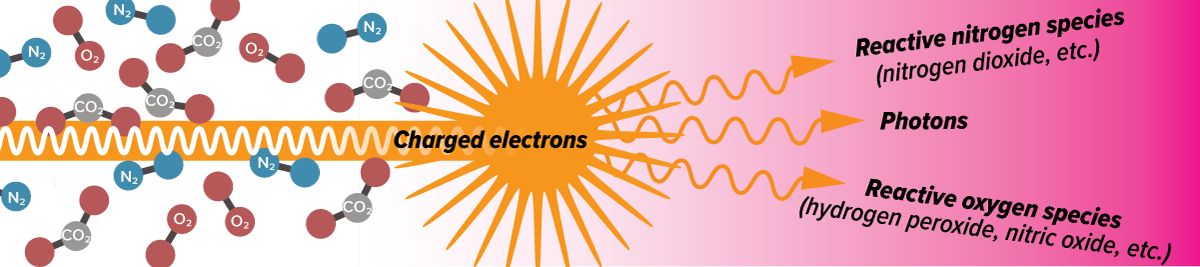

To create cold plasma, an electric current passes through gases such as nitrogen, oxygen, or air. As charged electrons hit the atoms and molecules with energy, electrons of the atoms in the gas are stripped away, creating an amalgam of free electrons and free ions. The gas itself remains at around room temperature since the combined mass of its electrons and their total thermal energy cannot transfer sufficient heat to other surfaces. However, the formation of cold plasma results in production of energetic reactive species, such as ultraviolet (UV) photons, electrons, ions, free radicals, and excited or non-excited molecules including hydrogen peroxide, nitric oxide, and nitrogen dioxide.

Cold plasma technology is important for sterilization, plant germination, wound-healing, soil reclamation, water treatment, dentistry, and oncology. In this article, we discuss how Alicat’s pressure and mass flow controllers are used in various cold plasma applications.

Sterilization

Cold plasma can efficiently sterilize surfaces from various bacteria, fungi, and viruses. In fact, cold plasma disinfection is more effective than ultraviolet sterilization. Because cold plasma disinfection doesn’t actually heat objects, it provides an ideal temperature-sensitive solution for food and medicine processing.

Challenge: Flow and pressure control of unique input gases

Flow solution: Standard MC-Series mass flow controllers are customizable for 98+ gases and can store up to 20 mixed gas calibrations. Anticorrosive MCS-Series mass flow controllers offer an additional 32 corrosive gas options for as many as 128+ gases. Both options are available for flow rates ranging from 0.5 SCCM to 5,000 SLPM with accuracy to ±0.5% of reading or ±0.05% of full scale and a control range of 0.01-100% (10,000:1 turndown).

Pressure solution: PCD-Series dual valve pressure controllers can regulate the pressure of a cold plasma chamber to an accuracy of ±0.25% of full scale, with a measurement range from 0.01-100% of full scale, allowing for sub-atmospheric plasma creation and lower energy requirements.

Wound-healing

Cold atmospheric plasma (CAP) provides new solutions in wound healing. Modern studies show that CAP eliminates bacteria and quickens the healing process without harming normal tissue in humans. Moreover, CAP effects the inflammation of wounds by stimulating growth factors, allowing wounds to heal more quickly and safely. Additionally, CAP acidifies wounds, further promoting quicker healing.

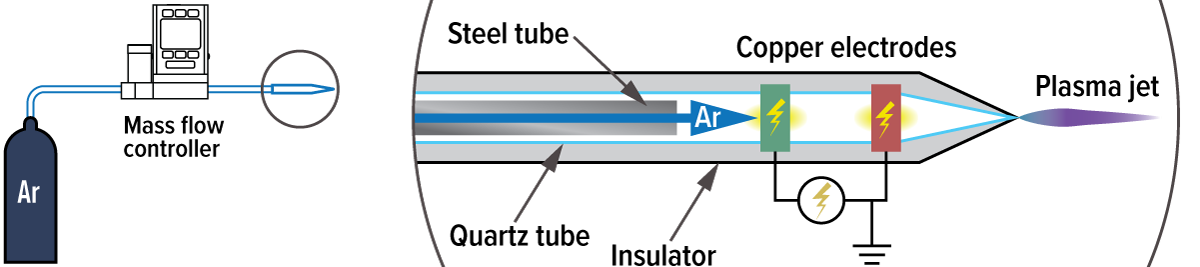

Challenge: Making well-characterized plasma jet tools for treating different sizes of internal and external wounds.

Solution: Alicat’s mass flow controllers have been used extensively for scientific research to create cold plasma jets, including characterizing an argon atmospheric pressure cold plasma jet. Alicat’s devices have appeared in over 1,000 scientific papers and are recognized for their repeatability and reliability in research applications.

Soil reclamation and water treatment

Cold plasmas also provide solutions for decontamination and modification of soil and water. Due to its radicals, cold plasma can remove toxins such as PFAS “forever chemicals” and oil sludge in both soils and fluids. In another study, cold plasma removed 90-99% of pharmaceutical residues from wastewater.

Challenge: Aerating plasma into water and selectively reducing toxins, unwanted fungi, and detrimental bacteria while preserving beneficial fungi and bacteria

Solution: Alicat’s mass flow controllers can work in series for testing various gas mixes in soil remediation. By adjusting the final plasma composition using Alicat devices, different toxins can be targeted. Moreover, Alicat’s mass flow controllers can help to control plasma aeration flow rates, resulting in more precise water treatment and less wasted plasma.

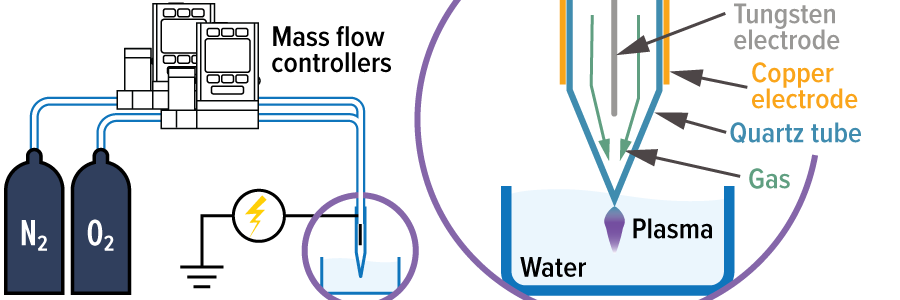

PAW fertilizer

Plasma activated water (PAW) is created by mixing cold plasma with water. When nitrogen rich gases are used in the process, PAW generates nitrogen fertilizer. PAW fertilizer uses a similar process as natural nitrogen fixation, converting N2 gas into NOx which reacts with O2 to create nitrates (NO3) that mix into the water. Relative to the Haber-Bosch process of making nitrogen fertilizer, which consumes 1-2% of the world’s total energy, PAW is cheaper to manufacture, uses less energy, and works at standard temperatures and pressures.

Challenge: Control of plasma aeration for different sized volumes of water.

Solution: When creating PAW fertilizers, higher plasma aeration flow rates equate to more nitrogen in the final fertilizer solution whereas lower flow rates equate to less nitrogen in the final fertilizer solution. Alicat’s mass flow controllers set accurate flow rates that can be adjusted via screen settings on devices, using FlowVision on a computer, or via PLC protocols, depending on the desired final NPK of a PAW fertilizer.

Dentistry and oncology

Cold plasma technology also has important applications for dentistry and oncology. Within dentistry, cold plasma technology creates solutions for bacterial inactivation, sterilization, teeth whitening, dental implant placement, and treatment of tooth decay.

Cold plasma has also been found effective for treating cancer, causing cancer cell apoptosis, growth inhibition, selective cancer cell death, cell cycle arrest, DNA and mitochondrial damage, selective increase of ROS, or immunogenic cell death. Studies even suggest that cancer cells are more sensitive to cold plasma treatment than normal cells, causing less cytotoxicity in nonmalignant cells.

Challenge: The development of products for niche applications. For example, a cold plasma “scalpel” kills cancer cells using cold atmospheric plasma while sparing normal cells and tissues.

Solution: Alicat’s mass flow controllers help to optimize plasma flume length and width in the creation of precise cold plasma applications, allowing for research and development of new types of surgical tools.