Search this article

Aerating everything using mass flow instrumentation

Aeration describes the process of infusing air or other gases into liquids. Aeration is an important step in various industries, including food and beverage manufacturing, fish farming, and wastewater and soil treatment.

Aerating wastewater

Aeration is an important step in secondary wastewater treatment. In the activated sludge process, water treatment tanks are carefully monitored for correct nutrient removal. Air is added into the tank or lagoon using aeration pumps to promote the growth of desirable bacteria in the wastewater. Over time, these bacteria feed on the toxic waste in the wastewater, breaking down pollutants so that they can be more easily separated from the treated water. The bacteria then accumulate on the bottoms of the tanks and are recirculated back into the system, further increasing the rate of water cleaning. Aeration is additionally used for sludge storage tanks in order to avoid them becoming populated with harmful anaerobic bacteria.

Alicat’s mass flow controllers optimize these treatment processes by mitigating wasted oxygen and aeration pump use. The total tank volume can be multiplied with the solubility of air in wastewater to determine exact oxygen requirements. Alicat’s mass flow controllers can then supply exactly the right amounts of air or oxygen, reducing the cost of continuous pump use and limiting gas waste. Moreover, Alicat mass flow controllers can include custom batching and totalizer settings to further automate the aeration process. In such configurations, our devices can be set to cycle specific amounts of air or oxygen, repeatedly resetting the totalizer and starting the next batch as automated.

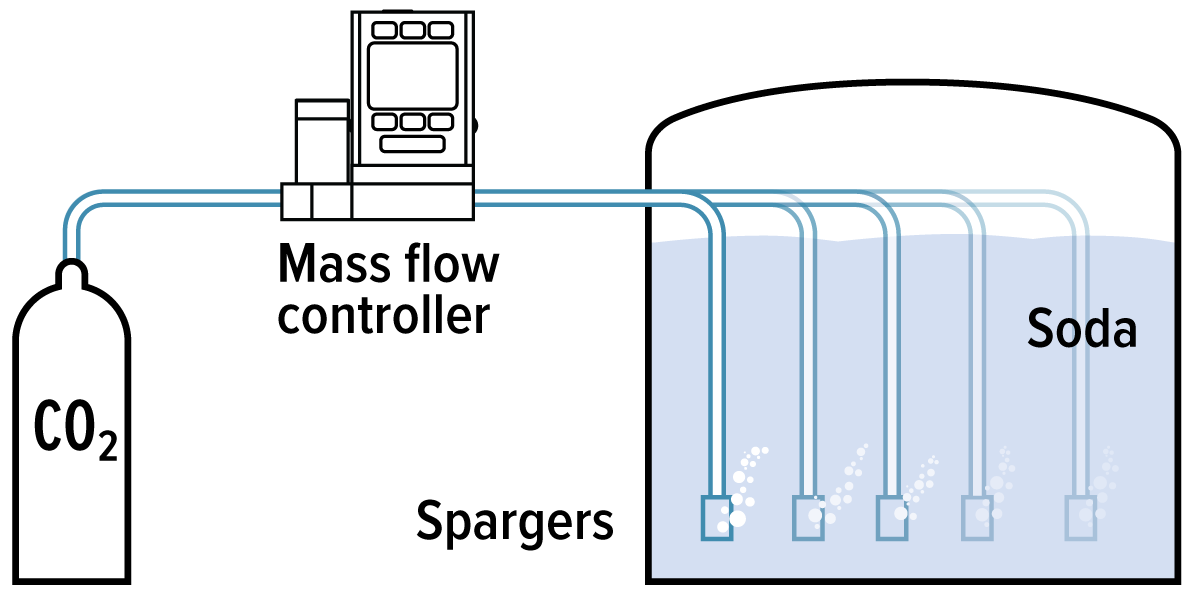

Aerating food and beverages

A wide range of foods and beverages are aerated, including confectionery, dairy products, egg foams, baked products, breakfast cereals, and beverages. Aeration improves the quality of certain foods by creating lighter textures, enhancing shelf-life and food appearances, and enriching flavors. Some common foods which use aeration include ice cream, chocolate and candy, cheese, beer, wine, soda, and pastries.

As an example, aeration is used to increase the oxygen content of wort and must (unfermented beer and wine) to allow yeast to increase their populations and the rate of fermentation.

A critical aspect of aeration within the food industry is repeatability and control of air bubble sizes during food processing. Alicat’s mass flow controllers allow for precise bubble size control during food processing by providing unique device options for controlling gas flow from 0.5 SCCM to 5,000 SLPM within an accuracy of ±0.5% of reading or ±0.05% of full scale and a control range of 0.01-100% (10,000:1 turndown).

Additionally, Alicat’s mass flow controllers can be built using ASME-recommended materials including 316L stainless steel and USP Class VI FDA-grade certified elastomers, allowing for safe direct contact food processing.

Aerating fisheries

With exception for a few microscopic animals that live in extreme environments, all plant and animal life on earth need oxygen. For all animals and plants living in water, proper oxygenation of the water is a necessity. If there is too little dissolved oxygen in the water source, plants and animals will die.

While this is not an issue in natural bodies of water where plants and animals have enough oxygen due to sufficient surface agitation, in artificial lakes and aquariums, which are much smaller than natural water bodies, oxygen must be additionally supplemented.

Therefore, it is either necessary to artificially agitate the surface of an artificial lake or aquarium tank or to use aeration pumps to dissolve additional air or oxygen. Based on the size of the water body, this can be very costly.

Alicat’s mass flow controllers can deliver exactly the right amount of air or oxygen using totalizing and batching options, improving process efficiency since aeration pumps are costly to run and it is important to avoid oversupplying the tank with wasted air or oxygen resources.

Furthermore, in combination with a computer or PLC and dissolved oxygen sensors which are used to collect data on the amount of oxygen in the tank, Alicat’s mass flow controllers can increase or decrease air/oxygen flow at specific dissolved oxygen measurements, further improving process efficiency for perfect 24/7 automated control.

Additional aeration support

Aeration is also used for additional applications such as removing gases like carbon dioxide or chlorine from water sources, laminating the flow of tap water at the faucet, or oxidizing suspended compounds in liquids.

Whether your process requires precision, repeatability, accuracy, or automation, Alicat’s mass flow controllers provide the latest tech and fastest results for both liquid and gas aeration applications.