Search this article

Inchfab uses mass flow and pressure control in nanoscale fabrication systems

Cowritten by Alicat; Mitchell Hsing, Ph.D., CEO & Co-Founder of Inchfab; and Parker Gould, Ph.D., CTO & Co-Founder of Inchfab

Background: Nanoscale fabrication systems & Inchfab

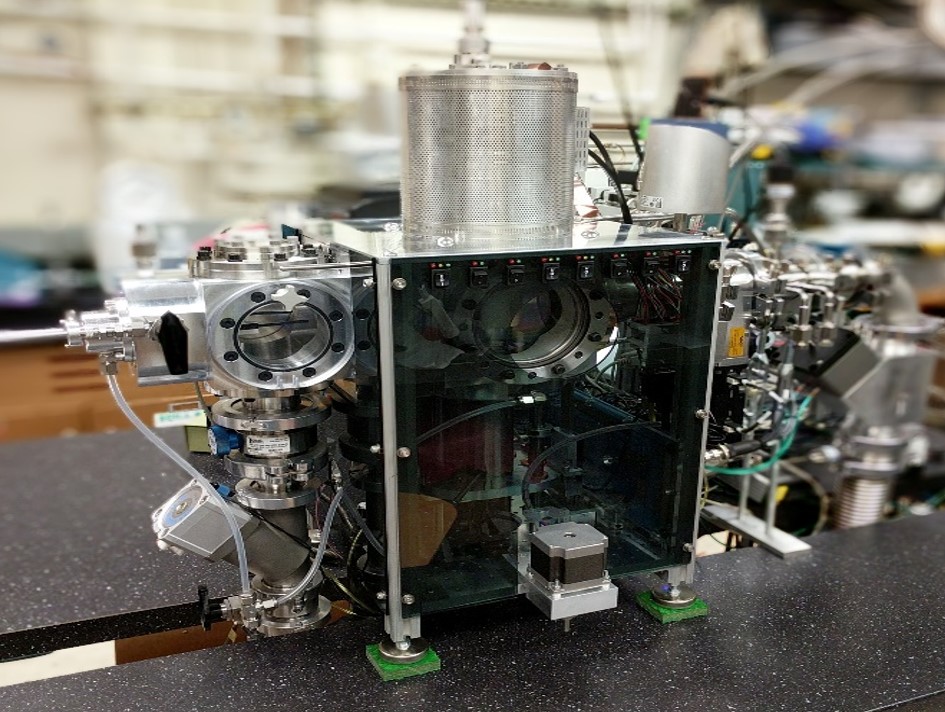

Figure 1. Prototype Inchfab ICP-CVD system

The increasing demand for computing power over the past 60+ years has led to exponential increases in both device complexity and production volumes. To keep up with this demand, the latest advances in micro- and nanofabrication technology have become inextricably coupled with increasingly larger substrate sizes. This has led to some of the most awe-inspiring engineering feats in history.

Not surprisingly, accomplishing such feats has neither been cheap nor easy. The capital cost of modern nanoscale fabrication facilities (“fabs”) now routinely stretches well into the billions of USD and requires strict process controls that severely limit the types of devices that a single fab can create. The high cost and minimal flexibility of nanoscale fabrication has become a major barrier in many different markets for groups seeking to develop innovative devices.

Mitchell Hsing and Parker Gould, co-founders of Inchfab

Inchfab’s novel platform of ultra-low-cost, high-performance fabrication tools is tearing down that barrier by decoupling advanced processing capabilities from large substrate sizes. By stepping back from the 150–300 mm (≈1 foot) diameter substrates commonly used in high-volume production today, the capital cost and physical footprint of the tools and facilities needed for nanoscale fabrication can be decreased by orders of magnitude, radically increasing their accessibility. Additionally, Inchfab has demonstrated that the use of smaller substrates can also lead to performance improvements over existing commercial tools. See their prototype ICP-CVD system in Figure 1, below.

Challenge 1: Repeatable, uniform mass flow control

Two of the most important characteristics required of micro- and nanofabrication systems are run-to-run repeatability and spatial uniformity. Achieving high levels of repeatability and uniformity relies on the ability to control many different process inputs and environmental conditions. Among the most important of these are mass flow rates and process pressures.

Solution: Laminar differential pressure mass flow control

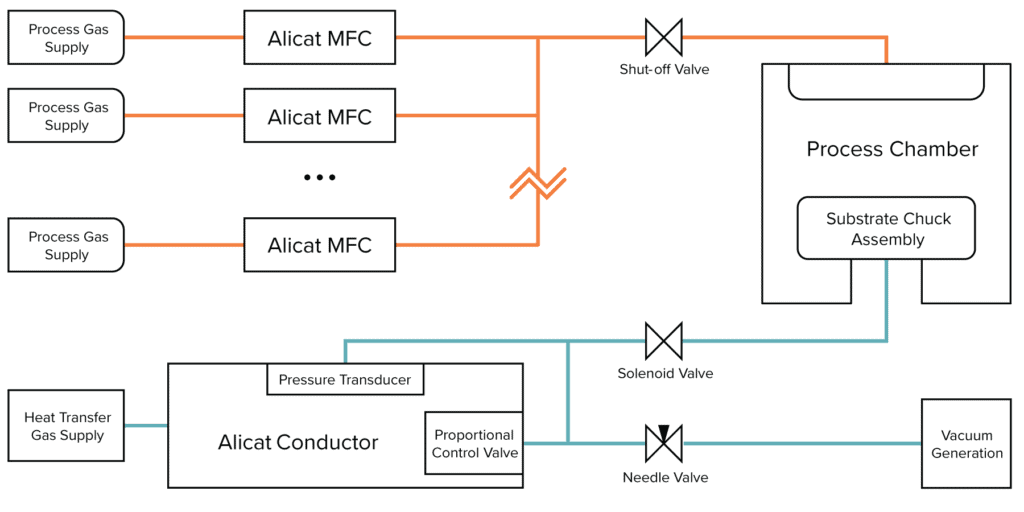

Figure 2. Block diagram showing how the Alicat controllers are used in the Inchfab ICP-CVD system.

Inchfab needed an affordable mass flow solution with fast response times, wide operating ranges, and no warm-up times. They ended up choosing Alicat mass flow controllers (MFCs), primarily due to the benefits stemming from their laminar differential pressure-based operating principle. These controllers provided Inchfab with high-accuracy measurements to 0.6% of reading, 30 ms response times, a control range of 0.01 to 100% of full scale, and no warm-up times. Figure 2 shows how Alicat MFCs are connected in Inchfab’s ICP-CVD system.

Challenge 2: Repeatable, uniform substrate temperature profiles

Just like reliable mass flow rates, repeatable and uniform substrate temperature profiles are also essential for consistent and uniform deposition and etch profiles. For example, in plasma-based etching, excess substrate heat is generated largely from bombardment from energetic particles generated in the plasma discharge and exothermic chemical reactions on the substrate surface. For fluorine-based silicon etching, as the substrate temperature increases, the etch rate decreases and commonly used masking materials like photoresist can begin to erode, decreasing selectivity. To counteract this heating, heat exchangers are used to conduct heat away from the substrate. Because the substrates being processed may have delicate features on their backside, direct thermal contact with the chuck assembly is not advisable. Thus an effective solution is to introduce a layer of heat-conducting gas between the substrate and the chuck.

Solution: Integrated vacuum pressure control

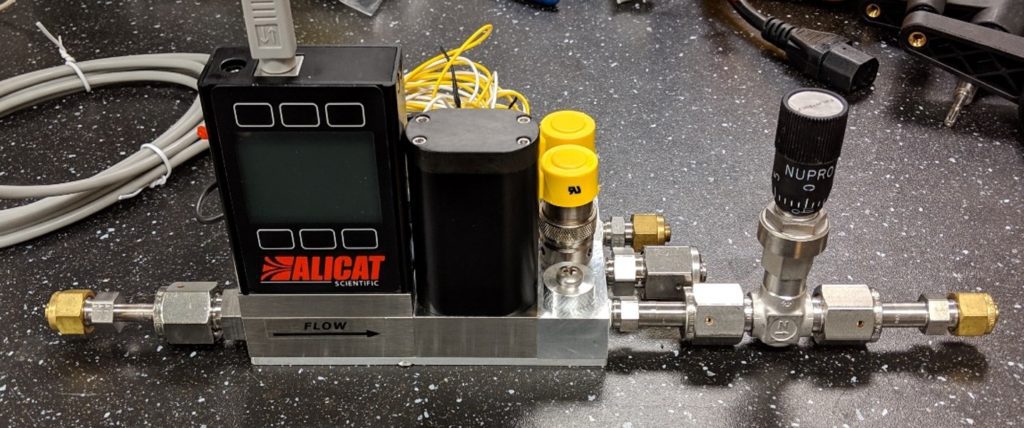

Figure 3. Alicat IVC-Series pressure controller with additional manifold for substrate heat transfer

To improve heat transfer between chuck assemblies and the substrates being processed, Inchfab used an Alicat IVC-Series pressure controller (see Figure 3). This pressure controller maintained sub-atmospheric gas pressures (typically 5–20 torr, depending on the process) on the backside of the substrate, minimizing the time needed to reach thermal equilibrium with the chuck assembly and maintaining equilibrium throughout processing.

The vacuum sensor in the IVC pressure controller provided precise, gas-independent pressure measurement in the substrate-chuck layer, with the ability to be routed independently of the fluid outlet. Inchfab was able to replace a more expensive controller with this device and removed several extra pieces of control hardware due to a common digital interface between the IVC and the MFCs. They were also able to use the standard intuitive Alicat digital communications protocol, making it very simple to monitor the pressure and update setpoints whenever needed. Figure 2 shows how the IVC (labeled Alicat conductor) is integrated into Inchfab’s ICP-CVD system.

Conclusion

As a member of the Activate – Cyclotron Road program at Berkeley National Lab, Inchfab is working with its partners to provide innovative and economical fabrication solutions for the micro- and nanoscale device community. Inchfab continually strives to refine and expand its micro- and nanofabrication capabilities and continuously looks for new technology that can assist in that effort.

Contact an applications engineer to discuss your process control methods