Search this article

Verifying and optimizing gas chromatography processes

Gas chromatography (GC) is an important analytical technique used to separate and analyze chemical components in a mixture. Here, we provide a brief introduction to GC and discuss some of the common application challenges and mass flow/pressure solutions.

How does gas chromatography work?

The sample is first injected into the inlet of the GC, where a steady flow of an inert “carrier gas” is used to move it through a packed column. As the sample passes through the column, the various components interact with the column material. Each component elutes at a different rate, depending on how strongly it interacts with the column. The outlet of the column feeds directly into a detector that characterizes the eluted compounds based on column retention time and signal strength. Eventually, the sample and carrier gas are vented out as waste.

Maintaining constant carrier gas flow

It is critical that the GC outputs accurate, repeatable results to ensure differences between two sample injections are only due to differences in chemical composition. It is therefore imperative to keep the flow rate of the carrier gas constant, as deviations disrupt the detection of chemical compounds.

Alicat makes fast, precise, highly accurate mass flow controllers that can be used to deliver exacting inert gas flows to your GC column. They provide the following benefits to GC applications:

- Stable, low-flow control: Even in low flow conditions, Alicat mass flow controllers provide stable flow from zero to full scale within tens of milliseconds.

- Versatile gas compatibility: One controller can measure 98+ gases and custom gas blends, including common inert gases like N2, He, Ar, and CO2.

- Easy to integrate & use: Devices come standard with 6-button backlit displays for easy control, or you can connect via a variety of industrial communication protocols.

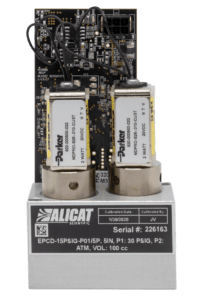

Maintaining stable pressure control with fixed orifices

Gas chromatographs with fixed orifice valves require stable pressure control. A common solution is our OEM pressure controller (EPC-Series), which provides numerous benefits to GC applications, including:

- Compact & easy to integrate: These compact controllers are easy to integrate into pre-existing setups, and can be customized to almost any flow rate, pressure condition, or speed required for GC applications.

- High quantity: These are a good option for high-volume OEM applications, as they are sold in batches of 25 or more units.

- Fast, versatile control: An EPC can be configured with either single proportional valves, dual proportional valves, or to control back pressure with control response times to 50 ms.

In addition, to use in gas chromatography applications, a single-valve EPC is ideal for regulating straightforward applications such as using a pressure regulator to knock down inlet pressure off a gas bottle, providing volumetric flow control against a calibrated orifice, or controlling stability in any desktop analyzer, lab in a box, reactor, or sample preparer.

Single valve electronic pressure controller

Dual valve electronic pressure controller

Verifying gas chromatograph operation in-house

The flow rate of the carrier gas in the gas chromatograph is critical to the accurate performance of the instrument. An Alicat portable mass flow meter is an accurate and versatile device that is capable of verifying the performance of a GC, such as the flow rate of the carrier gas. It can be used to check mass flow, pressure, and volume measurement on the input and vent of the GC.

These meters offer numerous benefits including:

- Fast, accurate, & repeatable: NIST-traceable accuracy of ±0.5% of reading or ±0.1% of full scale with <10 ms response times and a repeatability of ±(0.1% of reading + 0.02% of full scale).

- Highly versatile measurement: One device can verify both the pressure and flow of 98+ gases across a wide 10,000:1 operating range to cover both capillary and carrier gas flows.

- Easy integration into existing setups: RS-232 serial communications for data logging to any PC, PDA, or other device with serial terminal capability

Conclusion

Alicat has been working with customers on gas chromatography applications for over 25 years. Contact one of our applications engineers to find the best GC control or verification solutions for your process.